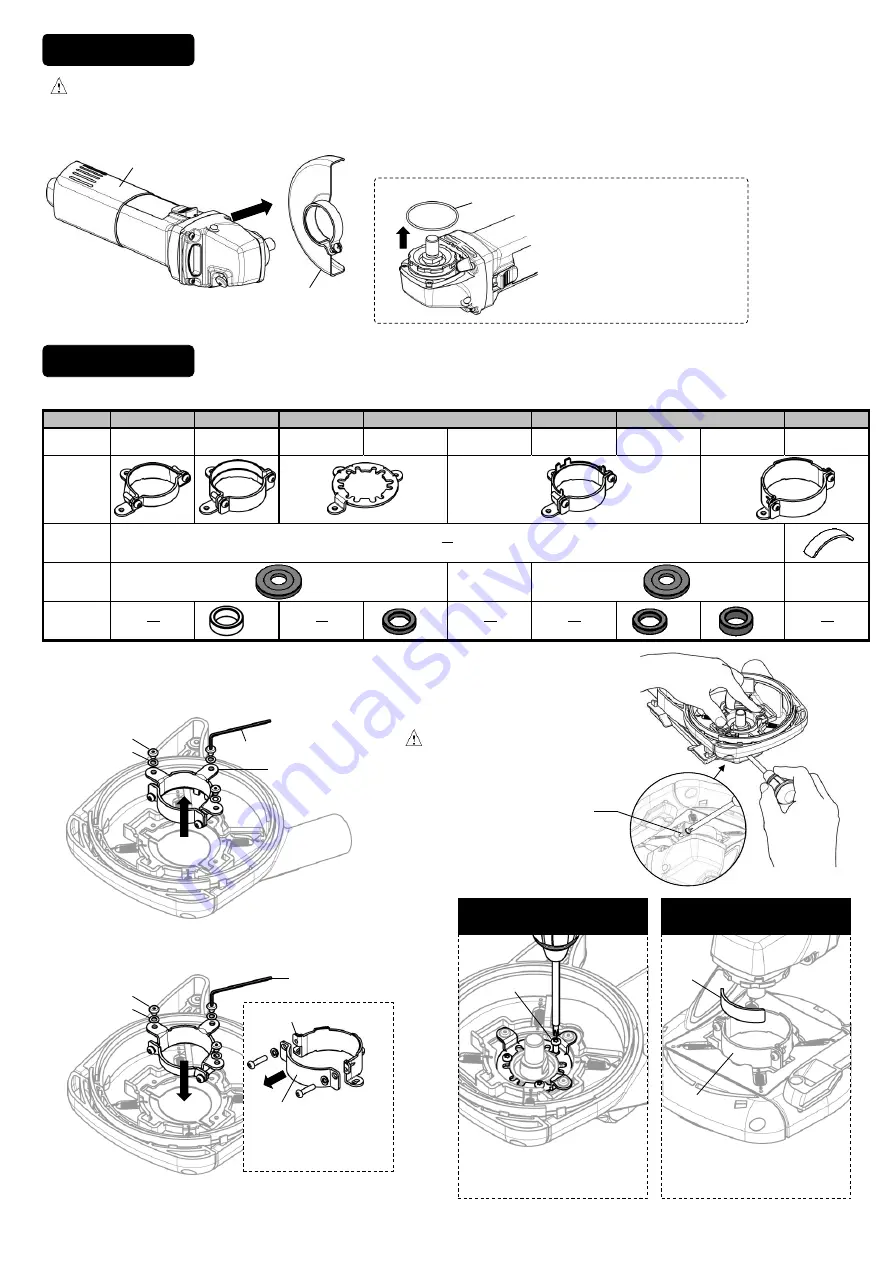

1. Choose the correct components for Angle Grinder to be used, according to the following table.

Brand

HITACHI

DEWALT

FLEX

MAKITA

METABO

Model

G13SR3/G13SB3

etc.

D28134 etc.

L3410FR etc.

AG8-125Q etc.

AG12-125X etc.

9558NB/9565CV/

GA4530 etc.

GWS8-125 etc.

GWS14-125CI etc.

WE14-125 Plus etc.

Connector

Collar

Flange

(Standard Flange)

(Standard Flange)

Spacer *

* When using a diamond cup wheels with the height 21mm.

MILWAUKEE

BOSCH

PREPARATION

WARNING

・

Be sure to turn off the angle grinder and remove the plug from the electrical outlet in advance.

・

If the connector is loose and cannot be securely attached on the angle grinder, do NOT use HURRICANE in this state.

otherwise it could lead to injury.

GWS8-115/GWS8-125/GWS10-125/

GWS11-125CI/GWS14-125CI

Remove O-Ring

if it is equipped.

O-Ring

INSTALLATION

-2-

Grinder

Guard

Take the Guard off from the Grinder.

T4.5

[d]

(Factory Preset)

[e]

[g]

[h]

[ f ]

[ i ]

[m]

[m]

T4.5

T7.3

(1) Loosen the screws by [k] Wrench and

remove the preset connector.

(2) Set the correct Connector and tighten the

screws. (Don't forget to fit the washers)

Hold 3points of the Connector and tighten

the fitting screws. (2pls.)

When using [f] B-connector,

take the Clamp Piece apart

before setting.

[ f ]

Clamp Piece

[ k ]

[ k ]

WARNING

Make sure HURRICANE is securely

attached, otherwise it may come loose,

causing injury.

Pre-set Connector

( [d] M-Connector )

Fitting screw

FLEX /

Milwaukee

(AG8/AG9 series)

2. Change the Connector. (if needed)

3. Fit on an Angle Grinder.

T7.3

iD16

[p]

[n]

[n]

[o]

Metabo

Tighten 3pcs of TORX screws as

fitted to the angle grinder.

Put [ i ] Collar between a Clamp

Piece and angle grinder.

TORX screw

Clamp Piece

[ i ]

Screw

Washer

Screw

Washer