Page -12-

N.A.C.E.

Operator's Manual -

SM1200 & SM1600

Steel Core Brush

WARNING: Turn off the switch and disconnect

unit from electrical supply before replacing

brush strips.

1. New brush strips inserts are supplied in sets. To

replace, first disconnect the machine from the

electrical outlet.

2. Remove the brush roll, see the section "How to

Replace the Belt."

3. Take the rubber end cap cover from the end of the

brush roll.

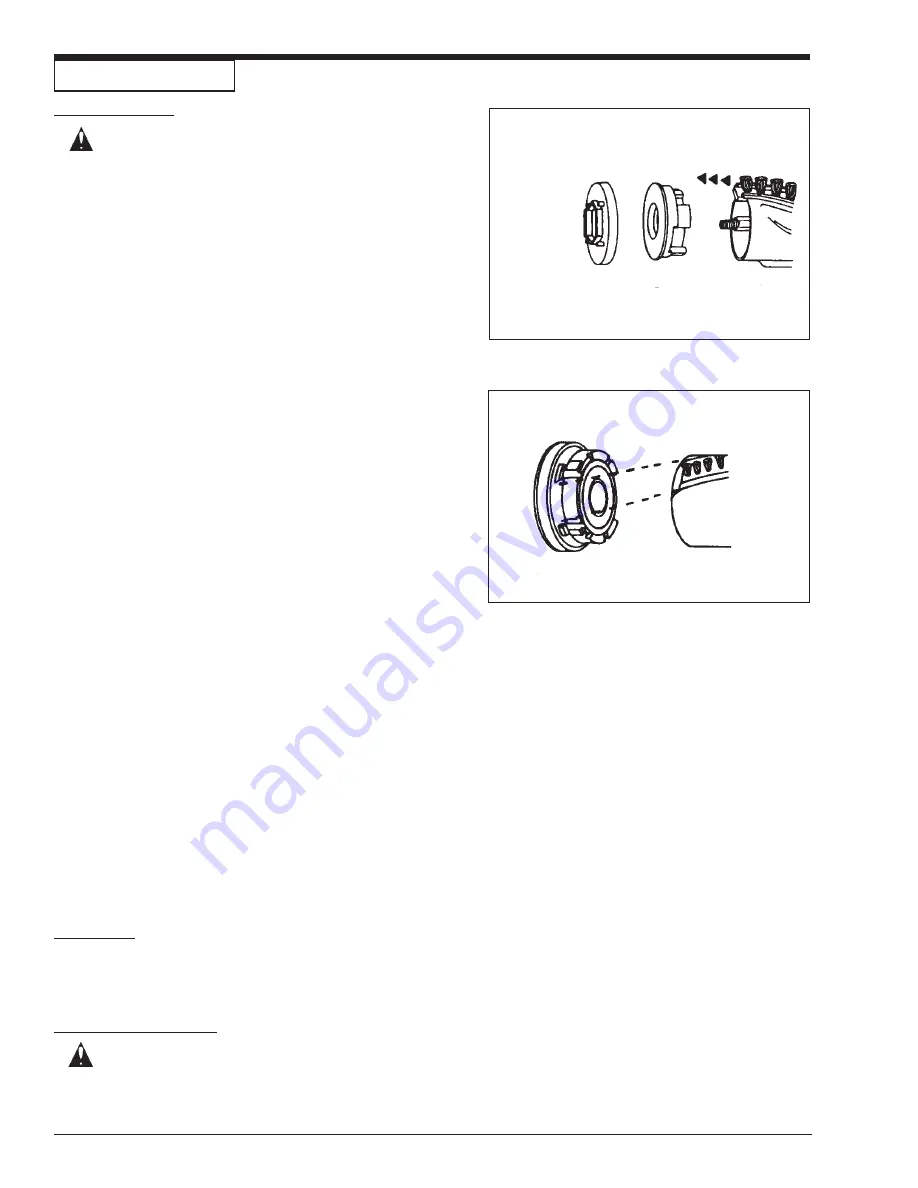

4. Remove end cap (figure 9, item A) and bearing retainer

(figure 9, item B).

5. Push the exposed end of the shaft (figure 9, item C)

through the opposite end of the brush roll.

6. Pull out the worn brush strips (figure 9, item D) with

pliers and slide in new ones of the same length,

inserting the rounded end first.

7. Fit the track on either side of the brush strip securely

into the brush roll slot.

8. Replace the other brush strips from the opposite end of

the brush roll.

9. Return shaft (figure 9, item C) and align the indentation

of the bearing retainer (figure 10, item B) with the brush

strip on both ends. Seat firmly.

10. Tighten endcaps (figure 9, item A).

NOTE:

Endcap covers are color coded. Reinstall the

brush assembly with the color coded endcap cover and

the color coded main frame base.

11. Add the end cap cover.

12. When properly assembled, the brush roll should rotate

freely between the two end caps.

13. Check the condition of the belt; change if necessary.

Replace the roll belt bottom plate, see the section

"How to Replace the Belt".

Lubrication

Do not oil the motor. The motor in this machine is

permanently lubricated and sealed. Do not oil the motor at

any time.

Electrical Maintenance

WARNING: Electric repairs and maintenance

must be done by authorized personnel only.

Return the machine to a N.A.C.E.Authorized

repair location.

MAINTENANCE (CONT.)

Figure 9

Figure 10

A

B

D

C

B