18

EN

hyperion

X5 2D/3D

- TECHNICAL MANUAL

EN

PC CONFIGURATION

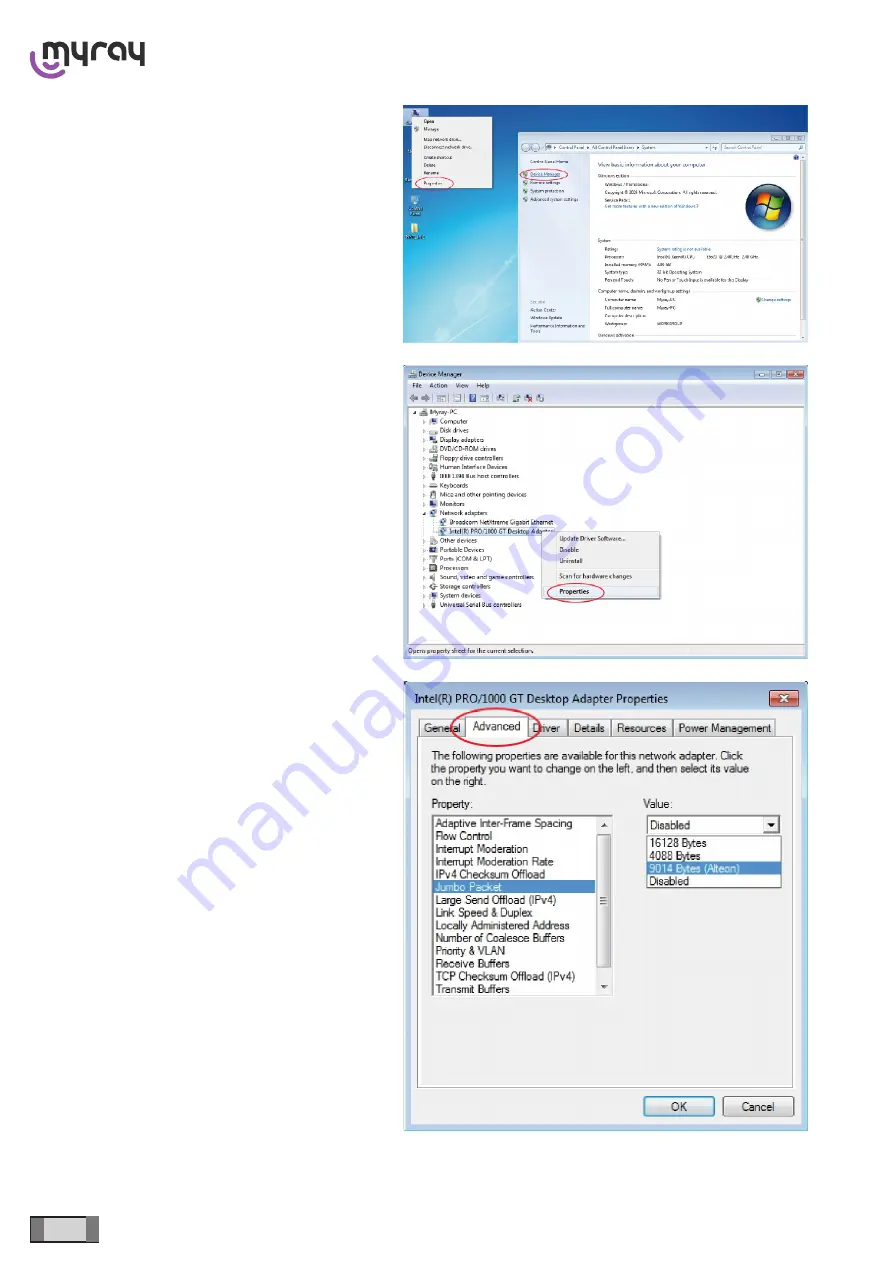

Right-click on “Computer”, select “Properties” and

select “Device Manager” in the left column.

Expand the “Network adapters” branch and right-click

on “Intel PRO/1000 GT Desktop Adapters”, select

“Properties”.

Select “Advanced” and choose the “Jumbo Packet”

property, setting the value to “9014 Bytes”.

Summary of Contents for Hyperion X5 2D

Page 1: ...www my ray com Cod 97071218 Rev 01 01 2017 hyperion X5 2D 3D technical manual EN ...

Page 2: ......

Page 4: ...2 EN hyperion X5 2D 3D TECHNICAL MANUAL CONTENTS ...

Page 37: ...35 EN hyperion X5 2D 3D TECHNICAL MANUAL EN CONTROL BOARDS DESCRIPTION ...

Page 40: ...38 EN hyperion X5 2D 3D TECHNICAL MANUAL EN CONTROL BOARDS DESCRIPTION PIN 4 signal X ray ON ...

Page 41: ...39 EN hyperion X5 2D 3D TECHNICAL MANUAL EN CONTROL BOARDS DESCRIPTION ...

Page 45: ...43 EN hyperion X5 2D 3D TECHNICAL MANUAL EN CONTROL BOARDS DESCRIPTION ...

Page 47: ...45 EN hyperion X5 2D 3D TECHNICAL MANUAL EN CONTROL BOARDS DESCRIPTION 5 5 MONOBLOC AREA ...

Page 51: ......

Page 52: ......