26

EN

M1.3.BT200-BT200M.NLFREN 13112018

.1211 . V201301

- 6 -

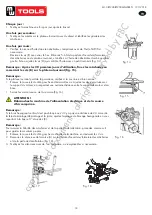

b. Demount tyre

1. Press tyre with right pressing roller C,G to a position 3cm lower than rim edge, lubricate tyre bead, rotate

turntable, lift roller C,G. ( Fig 9 )

2. Move demounting/mounting head close to edge of rim, keep a 2-3mm gap between demounting/mounting head

and rim plane

,

operate locking handle

(

K

,

Fig 4

)

to lock vertical arm

,

adjust screw bolt in column to position swing

arm, make sure 2-3mm gap between demounting/mounting head and rim edge side

3. Nearby demounting/mounting head, insert lift lever

N

into tyre

,

use lift lever to lift bead upon knob of

demounting / mounting head. Manually rotate roller C to inner side

,

pull handle D down, make roller C to press rim

,

keep 3-5mm gap between demounting/mounting head and rim, make sure demounting/mounting head not damage

rim, rotate turntable, demount tyre upper bead ( Fig 11)

4. Push handle D up

,

lift roller C,G

,

press switch F

,

loosen right pressing arm,

Lift tyre up, insert lifting level into bottom tyre bead nearby demounting/mounting head, lift bead upon knob of

demounting / mounting head and rotate turntable to demount down tyre bead

c. Mount tyre

1. Lubricate tyre and rim edge with lubricant to avoid damage of tyre. Adjust height of demounting/mounting head

and make tyre bottom bead upon rear of demounting/mounting head and below front of demounting/mounting head.

Rotate turntable to mount bottom bead.

2. Make tyre top bead upon rear of demounting/mounting head and below front of emounting/mounting head, move

right pressing arm and make sure it is locked, pull handle D down to make roller C,G to press top bead to position

below demounting/mounting head. Lock pressing block 1 on rim edge, rotate turntable, finish tyre mounting. (Fig

12)

11. Inflating the tire:

Importance: It is very dangerous during inflating operation, take carefully and

comply with instruction. When inflating, it will turn to be extremely dangerous if

problems happen to tyre or rim. The possible burst force tire goes upward and

outward, the big power may cause injury or death of the operator or the people

around

.

Tyre may burst caused by following:

1) The wheel rim and the tyre are not of the same size;

2) The tyre or the wheel rim is damaged;

3) The pressure of tyre inflation is over the max. pressure recommended by manufacturer;

4) The operator fail to comply with the safety regulation;

Please operate as follows:

1) Remove the valve cap from the valve stem;

2) Check to make sure the air nozzle is pressed down completely over the threads of the valve stem.

3) Check to make sure that the tyre and the wheel rim are of the same size;

4) Lubricate both the tyre bead and the wheel rim, additional lubrication is required if needed;

5) Inflate the tyre with break, while inflating, check the pressure listed on the pressure gauge, also check whether

the bead is fixed or not. Repeat operation above until the bead is secured; you need take special steps when inflating

convex rim or double convex rim;

6) Continue inflating and check the air pressure frequently until to reach the required pressure.

Note:

Never exceed the max. inflation pressure given by the tyre manufacturer.

Keep hands and your body away from inflating tyres.

Only specially trained persons are allowed to perform the operations, do not allow other to operate or be near

the tyre changer

.

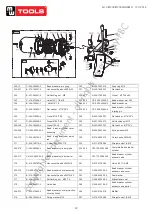

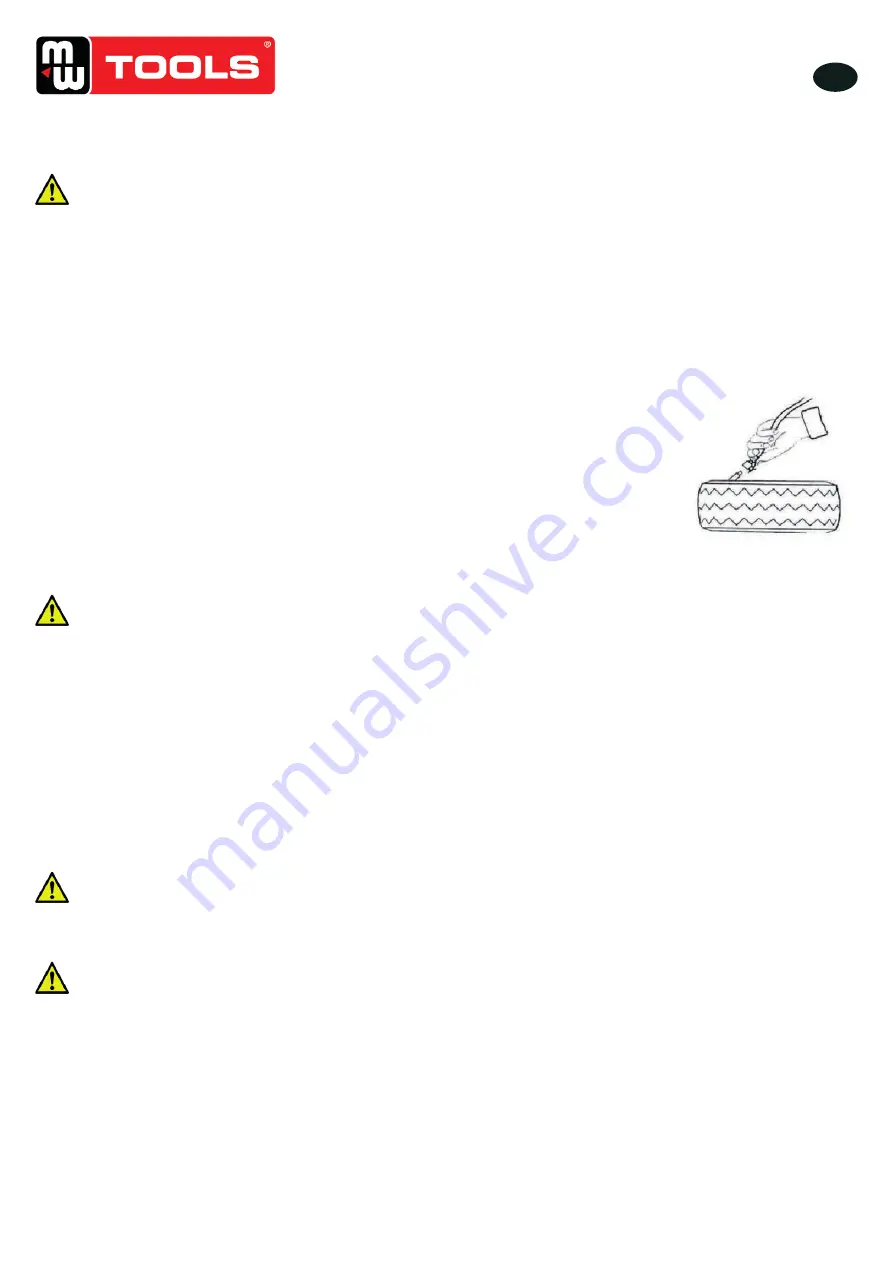

Fig 13

Fig. 13

11 Inflating the tyre

IMPORTANT!

It is very dangerous during inflating operation, take carefully and comply with instruction. When

inflating, it will turn to be extremely dangerous if problems happen to tyre or rim. The possible

burst force tire goes upward and outward, the big power may cause injury or death of the

operator or the people around.

Tyre may burst caused by following:

1.

The wheel rim and the tyre are not of the same size,

2.

The tyre or the wheel rim is damaged,

3.

The pressure of tyre inflation is over the maximum pressure recommended by manufacturer,

4. The operator fail to comply with the safety regulation.

Please operate as follows:

1.

Remove the valve cap from the valve stem.

2. Check to make sure the air nozzle is pressed down completely over the threads of the valve

stem.

3. Check to make sure that the tyre and the wheel rim are of the same size.

4.

Lubricate both the tyre bead and the wheel rim, additional lubrication is required if needed.

5.

Inflate the tyre with break, while inflating, check the pressure listed on the pressure gauge, also

check whether the bead is fixed or not. Repeat operation above until the bead is secured. You

need take special steps when inflating convex rim or double convex rim.

6.

Continue inflating and check the air pressure frequently until to reach the required pressure.

WARNING!

Never exceed the maximum inflation pressure given by the tyre manufacturer. Keep hands and

your body away from inflating tyres. Only specially trained persons are allowed to perform the

operations, do not allow other to operate or be near the tyre changer.

12 Moving machine

Please use forklift to move the machine. Disconnect the tyre changer from the electricity power supply and pneumatic power

supply, lift the base board and insert the feet of forklift. Then mount the tyre changer machine to a new position and fix it

tightly.

Note: The place chosen for fixing the tyre changer must meet the safety regulation.

13 Maintenance

CAUTION!

Only the professional persons can do the maintenance. To prolong the machine’s life, maintain

the machine timely according to the manual. Otherwise, it will impact the reliability of the

machine or even cause injury to operator and others nearby.

CAUTION!

Before performing any maintenance, disconnect the tyre changer from the electric power supply

and pneumatic power supply, and tread the jaws open and close pedal or turntable rotation

pedal for 3~4 times to evacuate all compressed air from the machine. Damaged parts must be

replaced with the spare parts provided by manufacturer.

copyrighted

document

- all

rights

reserved

by

FBC