VJ1638UH2E-I-02

6

VJ-1638UH Mark

Ⅱ

INSTALLATION MANUAL

4.2.2

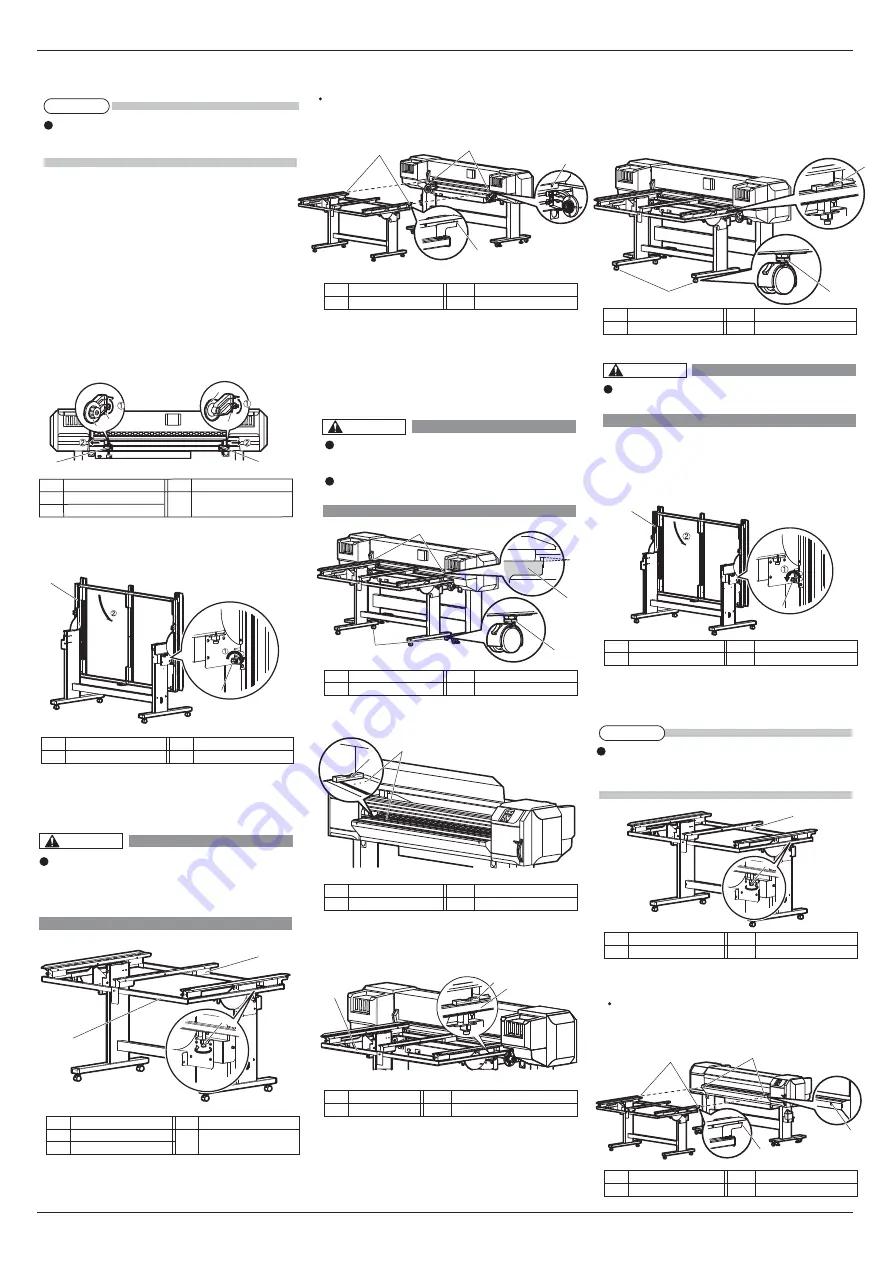

Installing the media-feed tables

(optional)

When Using the roll media for “10 Checking the

print condition”, you do not need to install

media-feed table.

When using rigid media on this printer, use

media-feed table (optional).

Follow the procedure below to install Media-feed

table.

The following items are required for installing

media-feed table:

4. Insert the positioning guide of media-feed table

into the square hole of Paper guide R.

8. Turn the screw of media-feed table’s caster (the

one further from the printer) with a spanner, and

adjust the slant.

9. Adjust the slant on the other side in the same way.

1. Loosen retaining screws of media-feed table, and

slowly level the table.

2. Tighten the leveling screws of media-feed table

(2 places, both sides), and fix the table.

3. Insert the positioning guide of media-feed table

into the square hole of Paper guide F.

If the height of the positioning guide does not

match the square hole, turn the screw of

Mediafeed table’s caster, and adjust the height.

(See step 4.)

When fixing the leveling screws, hold the frame

while pressuring the rubber foot, and then turn the

screw until it doesn’t turn any further.

If media-feed table’s slanted, media may

touch Print head, and Print head may break.

If the height of the positioning guide does not match

the square hole, turn the screw of Mediafeed table’s

caster, and adjust the height. (See step 5.)

Make sure that the position of the level’s air

bubble is at the same position as when you place

it on the printer.

(2)

Front side

5.

Turn the screws on the caster of media-feed table

(2 places, ones closer to the printer) with a spanner.

6.

Place the level at the edge of printer’s platen, and

check the position of the air bubble.

7.

Place the level on the frame of media-feed table.

Place the level on the same side as when you

placed it on the printer.

Adjust so that there is a 6 mm gap between the top

side of the square hole of Paper guide R and the top

side of the positioning guide.

Caster of media-feed table has 2 types

of screws.Turn the bottom screw.

Turn the screw clockwise to raise

Media-feed table.

• Spanner: Accessories for media-feed table

• Level: provided with the printer

(1)

Rear side

1. Loosen the fixing levers on the right and left side

of the rear. Set the distance between the roll media

holders wider than the roll media width.

2. Loosen retaining screws of media-feed table, and

slowly level the table.

3. Tighten the leveling screws of media-feed table

(2 places, both sides), and fix the table.

When fixing the leveling screws, hold

the frame while pressuring the rubber

foot, and then turn the screw until it

doesn’t turn any further.

Roll media holder

(

L)

Name

Roll media holder

(

R)

No.

Name

No.

Name

No.

Name

No.

Name

No.

Name

No.

Name

No.

Name

No.

1

2

Fixing Lever

3

Media-feed table

Leveling screw

1

2

Frame

3

Media-feed table

1

Leveling screw

2

Level

1

Frame of media-feed table

2

Name

No.

Name

No.

Level

1

Platen

2

Name

No.

Name

No.

Screw on the casters

1

Positioning guide

2

Name

No.

Name

No.

Media-feed table

1

Leveling screw

2

Name

No.

Name

No.

Media-feed table

1

Leveling screw

2

Name

No.

Name

No.

Positioning guide

1

Square hole

2

Name

No.

Name

No.

Positioning guide

1

Square hole

2

1

2

1

1

2

1

2

NOTE

CAUTION

1

2

2

1

1

2

1

2

3

NOTE

1

3

1

2

3

2

1

2

2

1

2

1

6mm

2

1

1

2

1

2

1

Name

No.

Name

No.

Scrwews on Casters

1

Level

2

CAUTION

CAUTION