VJ-1638UH Mark

Ⅱ

INSTALLATION MANUAL

VJ1638UH2E-I-02

12

•

The procedure for setting the rigid media is

complete.

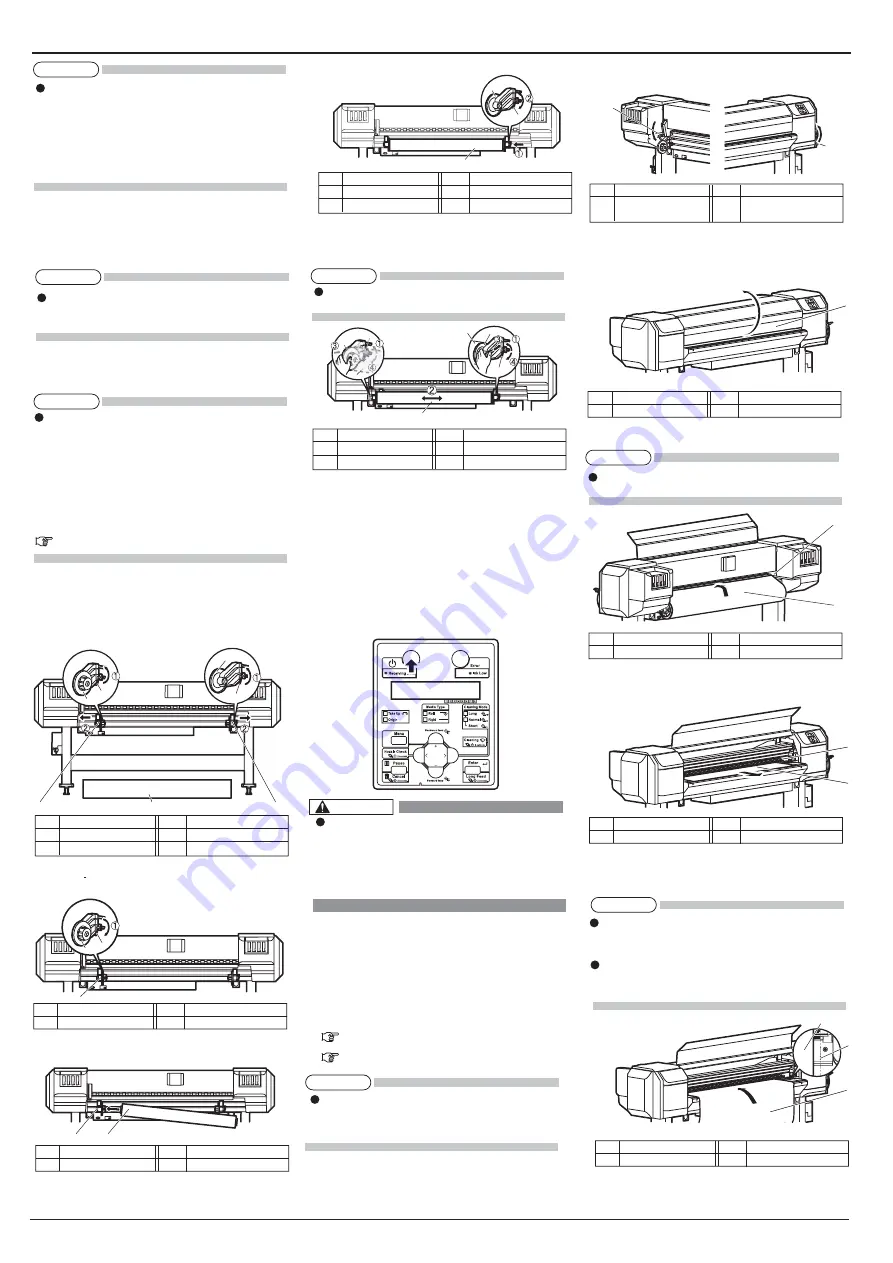

1. Loosen the fixing levers on the right and left side

of the rear. Set the distance between the roll

media holders wider than the roll media width.

2. Tighten the fixing lever on the left of Roll media

holder, and fix the Roll media holder (Left).

3. Set the roll media to the roll media holder (Left).

•

Printer has not been moved

•

Media type has not been changed

•

Outer diameter: 150 mm or less

•

Tube diameter: 2 or 3 inch.

•

Weight: 30 kg or less

•

Length: 50 m or less

•

Width: 1,625 mm or less

After fixing the caster height, even when

Media-feed table is removed, you do not need to

adjust Media-feed table’s height in the following

situation.

9.2 Loading roll media

The following roll media can be attached to the

scroller supplied with this unit.

Follow the procedure below to load roll media.

Operation Manual “8.1.1 Printer specifications”

For removing Media-feed table, read Operation

Manual “3.5.3 Removing Media-feed table

(optional)”

This section explains how to load roll media.

Place the roll paper on the side of the product origin.

Roll media holder (Left)

1

Roll media

2

Name

No.

Name

No.

Roll media holder (Left)

1

Fixing lever

2

Name

No.

Name

No.

Roll media holder (Left)

1

Roll media holder (Right)

2

Roll media

3

Fixing lever

4

Name

No.

Name

No.

NOTE

2

1

1

1

3

2

4

1

4

2

1

2

NOTE

NOTE

4. Set the roll media to the roll media holder (Right)

and fixed the fixing lever.

3. Raise Front media loading lever (lower Rear media

loading lever).

•

“Lever Up” is displayed on the operation panel.

4. Open the front cover.

5. Set the roll media to the media feed slot.

6. Pull the roll media out about 1 m from the front

media feed slot which is located inside of the front

cover.

7. Rewind the roll media a little by rolling the flange

on the roll media holder while holding the edge of

the media, and eliminate any slack or slant.

If you rewind the roll media too much, the roll

media may come off from Media feed slot and

may fall on the rear side of the printer.

If the right edge of the roll media is placed further

right of the loading mark, media detection may

fail, possibly affecting print quality.

If the end of the roll media is not wound tightly,

wind it tightly again, and then load it.

5. Loosen the fixing levers of the right and left roll

media holders, move the roll paper toward the

product origin and tighten the fixing lever.

•

The procedure for loading the roll media is

complete.

•

Set the roll media to the printer continuously

as shown below.

•

The printer starts the initializing operation.

•

“Media End” is displayed on the operation panel.

Operation manual “4.3.2 Menu setup procedure”

Operation manual “5.2.2.10 MediaType menu”

If the type of the media you have loaded differs

from that of the user type you have set, the media

may not be detected properly.

2. In Panel setup menu, check if the “media type” for

the User type you’re going to use is appropriately

set.

9.3 Setting roll media

This section explains how to set roll media.

Follow the procedure below to set roll media.

1. Turn the unit ON.

Do not operate the media loading lever

during initial operation and printing.

The print head portion may touch the

pressurizing roller portion, and cause a

malfunction.

Fix the roll media holders by pressing the

holders to the printer.

Name

No.

Name

No.

Name

No.

Name

No.

Name

No.

Name

No.

Name

No.

Name

No.

Name

No.

Name

No.

Name

No.

Name

No.

Name

No.

Name

No.

Roll media holder (Left)

1

Front cover

1

Roll media

1

Roll media holder (Right)

Roll media holder (Right)

2

Roll media

Roll media

Front media loading

Lever

1

Rear media loading lever

2

3

Media feed slot

2

1

2

3

Fixing lever

Fixing lever

4

Roll media

1

Media feed slot

2

Roll media

1

Media loading mark

2

1

1

2

1

2

1

2

1

2

1

NOTE

NOTE

1

3

4

3

3

4

2

NOTE

CAUTION

NOTE

3

1

2