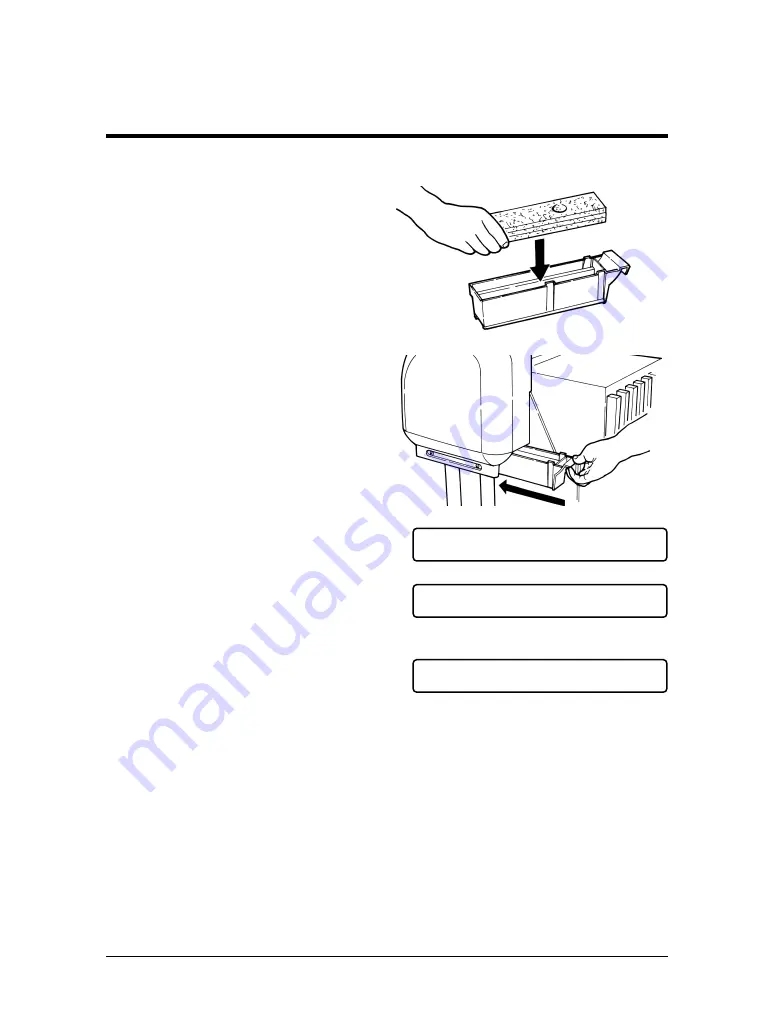

Step 3

Place the replacement waste liquid

absorbent sheet in the waste liquid box

with the hole towards the handle of the

box.

Step 4

Install the waste liquid box containing

the new waste liquid absorbent sheet in

the printer.

Step 5

The alarm will ring and "Change Tank?

No" is displayed.

Press the [VALUE +] or [VALUE -]

control panel keys to change the dis-

play to "Yes".

Step 6

Check that "Change Tank? Yes" is dis-

played then press [ENTER].

Waste liquid box replacement is fin-

ished and "Plot OK" is displayed.

86

RJ-6000 Series USER GUIDE Basic Edition

Replacing Waste Liquid Absorbent Sheet (Waste Box)

C h a n g e T a n k ?

N o

C h a n g e T a n k ?

Y e s

P l o t

O K