FW Murphy – CANdrive installation and operation 00-02-0618 revision F 7

th

January 2011 p3/4

Electrical Connection

CANdrive electrical connection is via a 12-

way automotive type receptacle shown right.

CANdrive models are available with the

connector facing forward through the front

label (‘F’ option, e.g. model CDV100F), or

rearward through the epoxy encapsulation

(‘R’ option, e.g. model CDV300R).

1

4

7

10

2

5

8

11

3

6

9

12

An 8-way, 30”/270mm wiring harness is available as

an additional loose item or as part of a CANdrive kit.

For customer-made harnesses, part numbers for the

mating connector plug and pins are as follows:

Murphy

part ref.

Molex

part ref.

Connector plug shell x 1

(1 required per unit)

79.70.1001 03-09-1125

or 03-09-1126

Connector pins, pack of 50

(max 8 required per unit)

79.70.1002 02-09-1104

Terminal functions

Pin Function

1

2

3

Negative DC, power supply

Positive DC, power supply

Negative DC, gauge common return

CANdrive is supplied for use with 12V (7 to 16V) DC

operation. If 24V (19 to 30V) DC operation is required,

push DIP switch S5 to the off (down) position.

Connect a 1 Amp anti-surge fuse in the positive DC line

(pin 2).

Pins 1 and 3 are internally linked: pin 1 is typically used

as a power supply connection; pin 3 is typically used as

a common negative return for the gauge outputs.

4

6

7

Oil pressure gauge output

Coolant temperature gauge output

Tachometer output

Pins 4 and 6 give a variable current output for driving

oil pressure and coolant temperature electric gauges.

The current output versus pressure/temperature is

specific to each gauge type, as selected using DIP

switches S1, S2 and S3 – see Configuration section.

Pin Function

Pin 7 gives a square wave output (0V to battery positive

DC), with a frequency proportional to engine speed.

At 1500 RPM engine speed, the output frequency is

119 Hz (±1%), suitable for driving charge alternator

based tachometers such as the Murphy ATA and ATHA

series. Pin 7 gives no output when engine speed is

below 100 RPM.

Connect each output to the appropriate gauge/

tachometer signal input. Connect gauge/tachometer

negative terminals to battery negative, ideally via

dedicated wiring to terminal 3. (The use of dedicated

return wiring to pin 3, rather than a ground/earth return,

minimises gauge inaccuracies caused by ground noise.)

5

8

CAN Hi

CAN Lo

Connect these terminals to the engine CANbus, taking

care to observe the correct polarity. The CANbus cable

shield/screen is typically connected to ground/earth at

one end only (often at the ECU): refer to the engine

manufacturer’s installation guidelines.

CANbus J1939 specifications require two 120 Ohm

terminating resistors at each end of the network.

CANdrive is supplied with a 120 Ohm network

terminating resistor in circuit. If CANdrive is not

positioned at the end of the CANbus network, switch

out the terminating resistor by pushing DIP switch S4

off (down) – see Configuration section for details.

9

10

11

12

Reserved for future use

Factory use

Factory use

Factory use

These connections are reserved for future use, or are

used in the factory setup of CANdrive. Do not connect

wiring or equipment to these terminals: connection may

result in permanent damage to CANdrive.

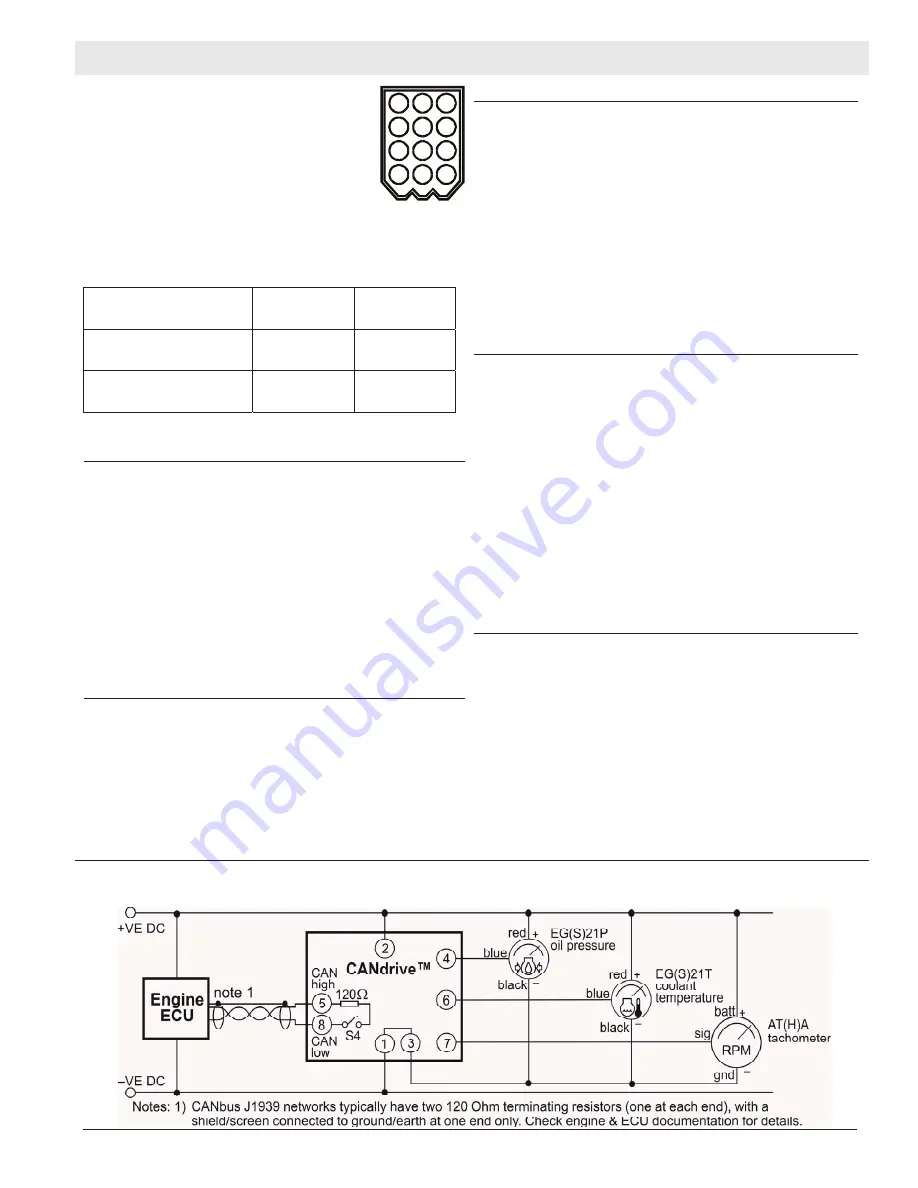

Typical Connection

Shown with Murphy EG(S) series gauges/Swichgages and AT(H)A tachometer.