13

Working with Zacki ELAPOR®

Zacki ELAPOR® has been developed specifically for glued joints in our models which consist of moulded ELAPOR®

foam parts.

Please observe the following points in order to obtain perfect joints:

• Avoid the use of activator. ‘Kicker’ significantly weakens the joint. We advise leaving joined parts for 24 hours to obtain

maximum strength, particularly when the glued area is large.

• Activator should only be used for temporary, small-area joints (‘tacking’). Spray a little activator on one surface, and

allow it to air-dry for about thirty seconds.

• To obtain maximum joint strength you should lightly sand the surface with 320-grit abrasive paper before applying glue.

Bent parts - actually don’t exist. If you find that a component has taken up a curve, perhaps after being trans

-

ported, it is easy to straighten again. In this respect ELAPOR® behaves in a similar way to metal: bend the

component back slightly beyond the correct position, and the material will then spring back to its proper shape

when released, and maintain it. There are limits, however - don’t overdo it!

Bent parts - really do exist.

If you wish to paint your model, apply MPX Primer # 60 2700 to the surfaces, wiping it on

very lightly as if you were cleaning the model. Paint must always be applied

thinly and evenly

, otherwise the component

will warp. Then you really will have bent parts, and they will also be heavy and perhaps even unusable. We have found

that matt-finish paints produce the best visual effect.

Specification:

Wingspan

975 mm

Overall length

1030 mm

All-up weight

min. 550 g

Wing area

approx. 29 dm² (FAI)

(FAI => wing + tailplane, excl. fuselage)

Wing loading

min. 19 g/dm²

RC functions:

Elevator

rudder

ailerons

motor speed

The

Centre of Gravity

is located at a point

110-120 mm

aft of the wing root leading edge (measured at the fuselage).

Note:

Please separate the pictorial pages from the centre of the building instructions before you start construction.

Tuning firewall

The

carbon firewall (motor bulkhead) # 33 2609

is machined from high-quality carbon fibre sheet material, and is

fitted with accurately made aluminium threaded inserts. If you intend to install this bulkhead, please note that a drop of

thread-lock fluid must be applied to the four thrustline adjustment screws (sidethrust and downthrust) once the correct

settings have been established.

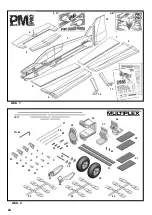

1. Before assembling the model

Check the contents of your kit before you start working on it.

You will find

Figs. 1 + 2

and the Parts List helpful here.

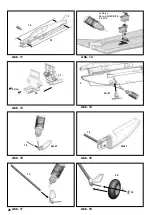

2. Preparing the fuselage

To improve orientation in flight it is advisable to paint the

dummy canopy of the fuselage 3 a dark colour, and this is

the best time to do it: mask off the canopy area with adhesive

tape, and start by applying a thin coat of MULTIPLEX MUL-

TIprimer

# 60 2700

. Wipe the primer off after application,

then finish the job with MULTIPLEX ELAPOR Color Spray

paint, e.g. grey

# 60 2710

. Apply the paint is sparingly as

possible; several very thin coats are best.

3. Preparing the elevator

Pack up the elevator

9

on the workbench (e.g. using two

books of the same thickness), so that it lies completely flat.

Glue the CFRP spar

16

in place, wiping off excess glue

immediately with a cloth. Use a balsa knife to cut slots at

the marked points for the hinges

22

.

Fig. 3

Prepare the elevator horn

23

as shown in

Fig. 4

before

gluing it in the recess in the elevator

9

. Secure the hexagon

nut with a drop of glue.

4. Preparing the rudder

Use a balsa knife to cut the slots for the hinges

22

along

the centreline of the rudder leading edge.

Fig. 5

Prepare the rudder horn

23

as shown in

Fig. 6

before gluing

it in the recess in the rudder

10

. Secure the hexagon nut

with a drop of glue.