Level Plus

®

Tank SLAYER

®

Operation Manual

I

15

I

6. Installation and mounting

6.1 Training

Warning:

When the pipe/hose of the LP-Series level transmitter is installed or

removed from the tank the release of flammable vapors will occur.

Take all necessary precaution when installing or removing the level

transmitter due to the release of flammable vapors.

Installation should only be conducted by qualified service personnel

according to IEC 60079-14 and local regulations or MTS trained

service technicians. MTS offers web based and in person training

for installation, commissioning, maintenance, and repair. MTS also

offers factory direct services for these same functions. Contact MTS to

discuss training or factory direct services before starting.

6.2 Stilling wells and guide poles

Level Plus

®

transmitters can be mounted in slotted or unslotted stilling

wells but a slotted stilling well is always preferred. Using a unslotted

stilling well will negatively affect performance of any level device as

the level in the stilling well can differ from the level in the tank. The

Level Plus

®

transmitter can also be installed to one side of the stilling

well to also allow for sampling and manual gauging from the same

opening as the automatic tank gauging. Contact technical support for

details.

Level Plus

®

transmitters do not require a stilling well for installation.

Our transmitters are installed in numerous tanks without stilling wells

with no loss in performance due to our patented flexible waveguide

and hose. A stilling well is highly recommended for agitated, turbulent,

and/or fast filling tanks.

6.3 Tools

• 9/16

"

Socket and ratchet

• Channel Lock pliers

• 3/16

"

Hex Key (Allen wrench)

• 1" Open End wrench

• Common head screwdriver, slotted screwdriver

6.4 Installation steps

Caution:

When assembling and installing the Tank Slayer

®

transmitter, be

careful not to allow the flexible hose to kink or be coiled in less

than 406.5 mm (16 in.) diameter. It is recommended that assembly

and mounting of this transmitter should not be done alone. To

ensure proper and safe assembly of the Tank Slayer

®

transmitter, a

minimum of two (2) individuals are recommended. Gloves are also

recommended. PPE may be required for work areas such as safety

shoes, safety glasses, hard hat, and fire resistant clothing.

1. Consult chapter 4.3 before starting.

2. Perform steps 1-10 in chapter 8.4.1 for Modbus or DDA. Perform

steps 1-9 in chapter 8.4.2 for Analog.

3. Remove the stop collar. With assistance, feed the flexible hose

through the hole of the removed tank flange until the flange

is positioned at the rigid section of pipe near the top of the

transmitter. Insert the threaded portion of the adjustable fitting

into the customer supplied flange and tighten (apply pipe thread

sealant if required). Be careful not to drop flange on the flexible

hose as damage may result.

4. Slide the product float onto the flexible hose. Slide the interface

float (optional) onto the flexible hose. Install stop collar 3 in.

from the bottom of rigid section (see ‘Note’ below). Do not

drop float(s) or allow them to free fall along the flexible hose as

damage may result.

NOTICE

The stop collar can be removed or adjusted based on the float

selected for the application. Please consult the factory for more

information.

5. Mount the hook, weight, or the magnet to the welded end-plug

section of the pipe (this is the bottom rigid section of the pipe)

using the supplied nut, spacer and washer, tighten securely

as shown in Fig. 8, Fig. 11 and Fig. 9. For the magnet, remove

washer before installing in tank.

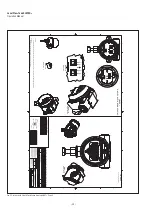

Fig. 8: Bottom fixing weight

Weight

Ø 5" (Ø 127 mm)

× 2" (51 mm) tall

Washer

Welded end-plug

Flexible hose

Float stop

collar

Spacer

Hexagon

nut