Figure 4-3

Section

T51 • E51

Page 509

Dated

February 2014

reassembly.

DO NOT attempt to

remove the seal using a screw-

driver or other sharp object.

Extensive damage to the shaft,

sleeve, or element could occur.

9. Before the motor bracket (#1) can

be removed, the four (4) “O”rings

(#8), located on the upper left and

right studs must be removed.

a. Gently tap on the back of the

motor bracket, alternating

between the left and right side,

until the motor bracket moves

approximately 1/4”.

b. Tap the motor bracket face to

move it back to its original posi-

tion.

c. Remove the “O” rings by sliding

them off the studs.

d. Slide the motor bracket straight

off. Do not attempt to remove

the motor bracket without first

removing the “O” rings (#8).

10.Remove the seat portion of the

seal, Refer to Figure 4-6.

d. Care must be taken with

the seats. They are often a

brittle material and are prone to

breakage.

It is

recommended

that a new replacement seat

be installed during reassem-

bly.

11.It is not necessary to remove the

locking collar (#14) on the motor

shaft unless motor repairs are

planned. Note the condition of the

setscrew in the collar and replce

if necessary. The two studs (#18)

may also be left in the motor face.

4C Disassembly (C15 and P15)

The following tools and equipment

are needed for disassembly of C15

and P15 units:

1. Soft plastic or wooden mallet.

2. 9/16” wrench or socket.

3. Two 10” or larger adjustable

wrenches.

4. Penetrating oil.

5. 1” wood dowel ( Approx. 6” long).

6. Thin blade screwdriver.

7. Two large blade screwdrivers.

8. Cealube G or similar glycol base

lubricant. (DO NOT use petroleum

products.)

To disassemble the pump:

Refer to Figures 4-11 and 4-12 for

reference to the numbered parts in

the disassembly below.

1. Remove all liquid from the pump.

2. Remove the two (2) 3/8” nuts

(#20), and the two (2) 3/8” X 4”

bolts (# 19) from the cover. (#2)

3. Remove the cover. In some

cases, light tapping with a plastic

or wooden mallet on the outside

diameter of the cover may be

required to loosen it from the

motor bracket. Care should be

taken if a screwdriver is needed to

pry between the cover and motor

bracket. Damage to the “O” ring

(#7) and/or impeller can result.

4. Remove the impeller (#11), refer

to Figure 4-7. The impeller is a

slip fit and, under normal condi

-

tions, can be removed by gently

tapping on the end of the shaft

sleeve with a mallet. Leave the

impeller key (#23) in place. Strik-

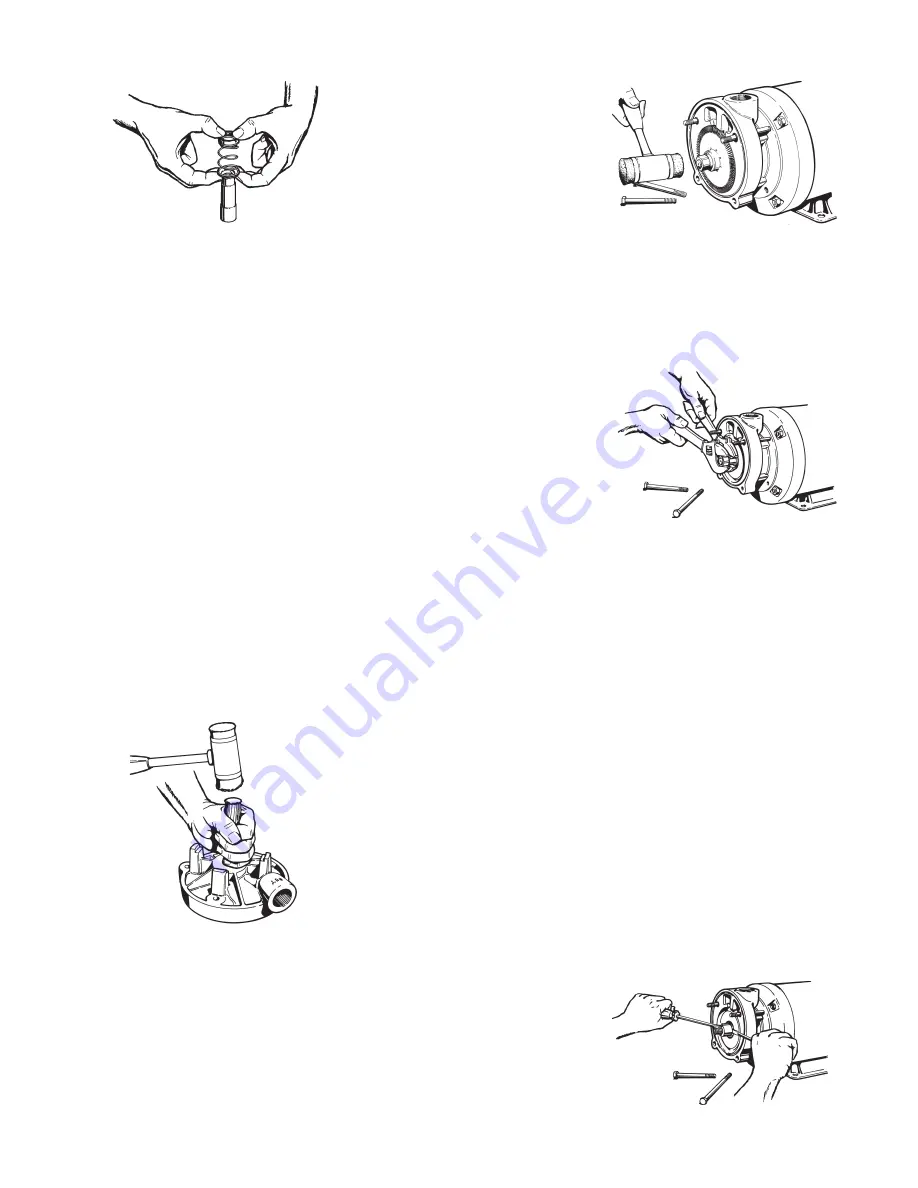

Figure 4-7

Figure 4-6

a. Place the motor bracket face

down on a flat surface.

b. Look into the opening in the

center of the bracket, you will

see a portion of the seat.

c. Insert the 1” dowel and, very

gently, tap the seat until it drops

out.

ing the sleeve too hard could

damage the seat or rotating ele-

ment.

5. Remove the impeller drive hub,

Refer to Figure 4-8. Two (2)

adjustable wrenches are used

to remove the impeller drive hub

(#14).

Figure 4-8

a. Adjust one wrench to fit over

the sleeve and engage the

impeller key. Adjust the second

wrench to fit the impeller nut

(#15).

b. Holding both wrenches, turn the

impeller nut counter-clockwise.

c. After the impeller nut is re-

moved, the impeller drive hub

can be removed.

d. The hub is keyed and can be

removed using two large bladed

screwdrivers.

e. Insert the blades of the screw-

drivers between the spring

holder on the rotating element

and the shoulder of the hub.

f. Holding the screwdrivers at

approximately 3 o’clock and

9 o’clock, push the handles in

toward the motor body, using

the motor bracket for leverage.

Refer to Figure 4-9. This pro-

Figure 4-9