8

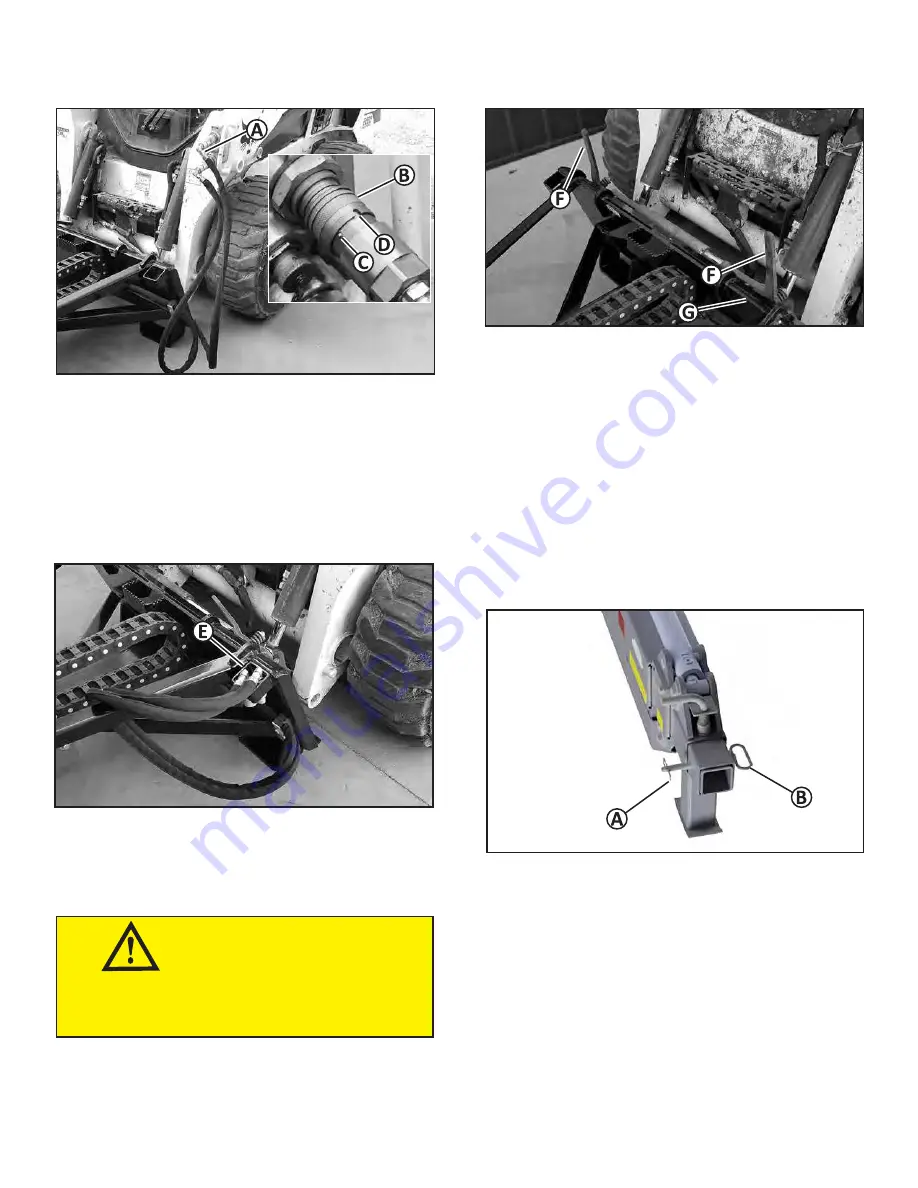

5. Disconnect the attachment hydraulic hoses from the

loader’s front auxiliary couplers (A).

a. Rotate the coupler sleeves (B) so the ball (C) is

aligned with the groove (D) to allow the coupler

to disconnect (Some sleeves may not have this

locking mechanism).

b. Grasp and push or pull the sleeves to disconnect

the couplers.

6. Install protective caps on the couplers if they are

provided, and store the couplers on the attachment

hydraulic hoses into the hose coupler storage area

(E) as shown.

WARNING

AVOID INJURY!

Loader attaching plate levers which are operated

manually may have spring tensioning. Firmly grasp

the levers and move the levers slowly.

7. Move the loader attaching plate levers (F) to the

unlocked (up) position as shown either manually or

by using the loader controls.

8. Tilt the loader attaching plate forward slightly and

drive the loader backward until the top edge of

the attaching plate clears the top flange (G) of the

attachment mounting frame.

Installing the Secondary Attachments

1. Install the telescoping boom attachment on the

loader.

2. Park the loader (See Parking Safely in this manual.)

3. Remove the pin (A) and hitch pin (B) from the end

of the manual extension tube.

4. Install the secondary attachment in the tube with the

hitch pin and pin.

Installing and Removing

Summary of Contents for 14592

Page 17: ...17 Replacement Parts...