Technical

issues

with

Jenny

Reloaded

VFD

clock

Please

read

carefully

!

On

some

Jenny

models

an

issue

occured

either

at

once

or

after

some

time

of

operation

that

the

MosFet

T2

runs

hot

and

the

clock

was

not

functional

anymore.

At

the

same

time

C13

and

/

or

C20

became

discolored

and

also

runs

very

hot

because

of

an

internal

short

circuit.

It

was

detected

that

this

ceramic

capacitors

were

taken

from

a

batch,

which

is

unable

to

withstand

the

47

V

operating

voltage

(the

spezification

of

the

capacitors

is

50

V)

for

a

longer

time.

Please

check

first,

which

type

of

capacitors

the

clock

is

equipped

as

follows:

Disconnect

the

clock

from

power

and

unscrew

out

the

PCB.

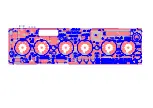

Locate

now

the

positions

of

C13

and

C20

with

the

help

of

both

left

illustrations

and

check

the

type

of

the

capacitors.

"Good"

capacitor

"Bad"

capacitor

No

modifications

Capacitors

C13

and

C20

need

to

be

made.

needs

to

be

un

‐

soldered.

The

clock

is

equipped

in

total

with

eight

of

this

100

nF

capacitors;

either

the

"left"

or

the

"right"

version.

The

possibility

of

a

failure

only

can

happens

on

C13

and

/

or

C20;

which

means

that

the

remaining

six

"bad"

capacitors

can

be

remain

soldered

in.

For

de

‐

soldering

capacitor

C13

/

C20

please

do

the

following

task:

Heat

up

both

solder

pads

of

each

capacitor

simultaneous

with

the

help

of

a

fat

drop

of

solder

tin

and

pull

out

the

capacitors

with

tweezers.

Next

clean

all

pads

with

a

de

‐

soldering

pump.

With

this

method

your

clock

is

temporarly

functional,

but

it

is

strongly

recommended

to

replace

C13

and

C20

with

100

nF

/

100

V

versions.

Furthermore

it

was

mentioned,

that

both

electrolyt

capacitors

C5

and

C6

are

driven

nearly

outside

their

voltage

range

(25V

each).

No

issues

were

reported

so

far,

anyway

it

is

recommeded

to

solder

both

electrolyt

capacitors

a

resistor

of

47

kohms

each

in

parallel

for

improved

voltage

‐

symmetry.

On

request

the

manufacturer

offers

a

free

upgrade

set,

composed

of

2

x

ceramic

capacitors

100

nF

/

100

V

and

2

x

47

kohms

small

sized

resistors.

Please

contact

the

manufacturer

via

at

These

modifications

only

affect

clocks

up

to

serial

‐

no.

JR

‐

267

Starting

from

serial

‐

no.

JR

‐

268

adequate

improvements

has

been

made.