3

T

b

is is an A for no special

the

mm shaft.

-3. Piping

1.

short as possible. Normally,

the suction line should be the same dia

the pump

sucti

r, conditions

required minimum flow velocities may dictate otherwise.

bows or 45-degree elbows

e standard elbow. Avoid using

the complete pump from the base.

ounted on a firm foundation. The motors should be supported

S

Before operating the pump for the first time, fill it with liquid

for the initial start-up.

temporarily, enough liquid will

brication upon restarting. It

some liquid in the pump at time of shutdown.

been filled with liquid, check for direction

y

f

disas

result in premature

packing failure and possible damage to the shaft and gland.

he next letter indicates whether there are any special options

ng used in the pump, typically th

ei

options.

The next letter indicates the suction configuration. For this

pump an A is used designating a standard flanged pump.

The last letter indicates the drive configuration and

flange/shaft/seal size. In our close coupled pump nameplate

designates a 250mm flange and 45

C

2-1. INSTALLATION

-2. General

2

Accessibility to the pump and adequate clearance should be

prime considerations in any installation. Enough space should

surround the unit so that maintenance can be performed with

ease.

2

Suction piping should be as

meter as

on; howeve

such as high viscosity or

3

Long-sweep 90-degree el

should be used instead of th

suction piping loops, which trap air.

2.

Discharge piping diameter should generally be as large as

the discharge port unless fluid conditions indicate

otherwise.

3. An easily removable section of piping, at least twice as

long as the stator, should be mated to the discharge port.

This will allow the rotor and stator to be removed without

having to remove

2-4. Foundation

For maximum pump-driver unit life, each unit should be

mounted on a strong steel baseplate. The baseplate should be

m

on close-coupled configurations above 30 HP.

3-1. OPERATION

3-2. Initial Check

Before putting the pump into operation, the following items

should be checked to ensure that each piece of equipment is

installed correctly:

Electrical

connections.

Gauges and other instruments.

Pump rotation. Rotation is indicated on the pump

nameplate.

All valves should be open on both suction and discharge

sides of pump.

eal flush systems if required should be operational.

Double seals require flushing between faces.

CAUTION: This is a positive displacement pump. Do not

operate it against a closed valve.

3-3. Start-Up

CAUTION: DRY OPERATION IS HARMFUL TO THE PUMP!

Never allow the pump to operate without liquid, as dry

operation will cause premature wear of the stator and possible

damage. The liquid being pumped lubricates the stator.

1.

to lubricate the stator

Note:

If the pump is shut down

remain in the system to provide lu

is advisable to maintain the suction piping at a higher

elevation than the centerline of the pump in order to contain

2.

Once the pump has

of pump rotation by momentarily starting and stopping the

drive. See pump nameplate for correct rotation.

3.

Start seal flush water if so equipped.

4. Start

pump.

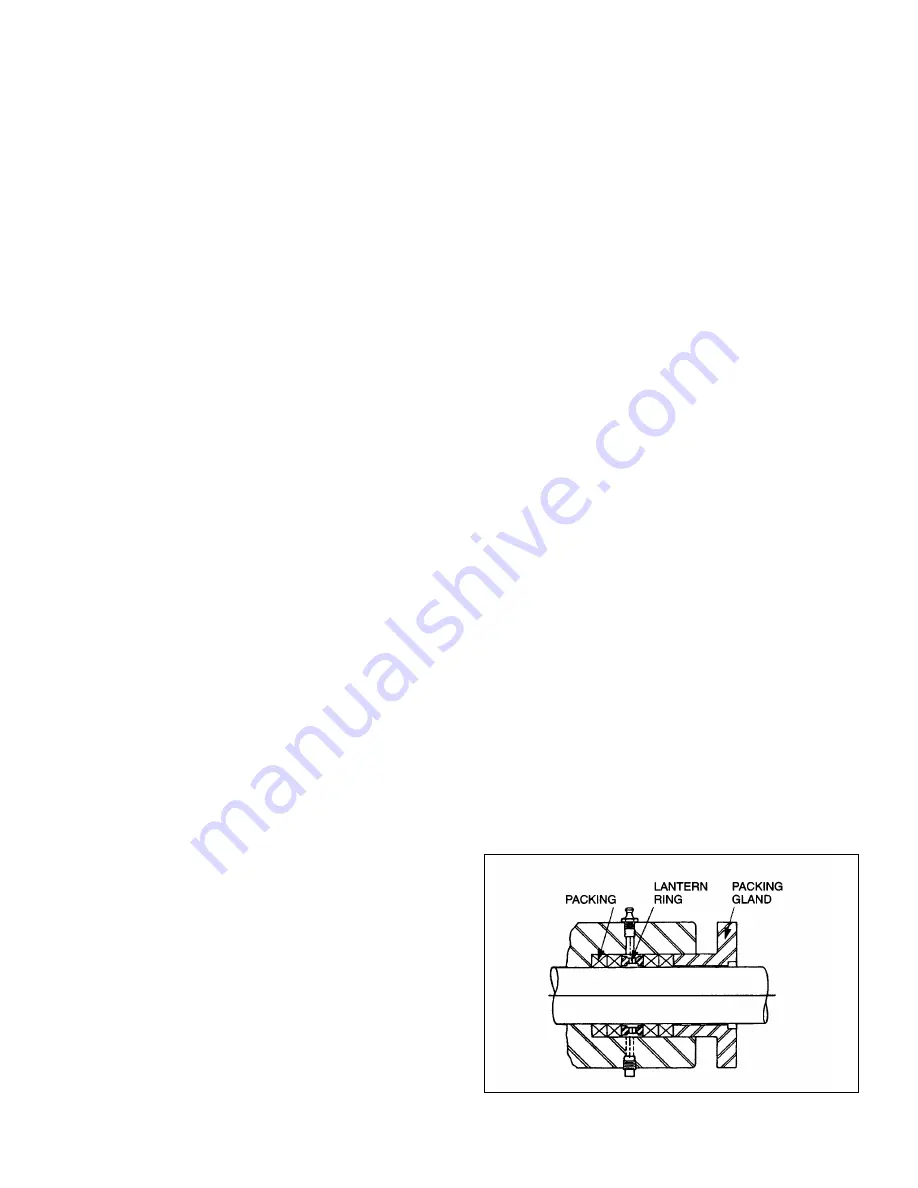

-4. Packing Leakage

The packed stuffing box is designed to control leakage, not stop

it completely. Leakage is necessary to reduce friction and

dissipate heat.

In a new pump, before the packing has had a chance to seat

properly, excessive leakage through the stuffing box is common.

Frequent adjustments of the packing gland may be necessar

during the first few hours of operation in order to compress and

seat the packing. See Section 4-3.

4-1. MAINTENANCE

4-2. General

The Moyno 2000 CC pump has been designed for a minimum o

maintenance, the extent of which is routine adjustment of the

packing. The pump is one of the easiest to maintain because the

main elements are very accessible and require few tools to

semble.

4-3. Packing Adjustment

Packing gland nuts (see Figure 4-1) should be evenly adjusted.

Overtightening the packing gland may

Summary of Contents for 2000 CC

Page 1: ...fCover Page Moyno 2000 CC Pumps...

Page 15: ...13...

Page 16: ...13 1 Seal Set Dimensions...

Page 17: ...14 1 TROUBLESHOOTING CHART...