DESCRIPTION OF THE MACHINE

M

0

© MOSA

REV.1 - 03/10

18/11/08 22262-GB

The engine driven welder is arranged as a single block composed of the engine and stainless steel box

structure where the front is the cover. All electrical components of the machine (except for the reactor

which is located on the base under the engine) are located inside, which are: an alternator with permanent

magnets, a high frequency chopper bridge, a control board for the welding current, an inverter which

generates alternating current of 50Hz with 230 or 110 volts and an electromagnet for the tick-over.

Main features:

•

D.C. welding current 200A al 60%

•

Continuous regulation of the welding current with "Chopper Technology"

•

Suitable for basic and rutile electrodes. A reactance for cellulose electrodes is available as an option

•

Antistick function (small arc force)

•

Continuous auxiliary output 50Hz to 230V/3kVA to 110V/2kVA (50 Hz/60Hz)

•

Engine accelerator at minimum/maximum at load take up

•

Weight 57 Kg

•

Acoustic Power 74 dBA to 7m

Electrical components of the machine:

•

Permanent magnet alternator: the alternator has 2 galvanically separated windings, one for welding and

the other for the auxiliary output.

•

Tick-over solenoid: an electromagnet in absence of load. When the load is present, welding or auxiliary

output, the electromagnet is not supplied any more and the engine speed goes to the maximum (4000

rpm rated open circuit).

•

High frequency chopper diode bridge: it regulates the welding current using the “Chopper Technology”,

which chops the welding D.C. current at high frequency.

•

Hall sensor: it measures with high precision the welding current and it’s completely isolated from the

welding circuit.

•

Serie's reactance

•

Welding current adjustment board: a board controls the welding process and supplies the engine acce-

lerator control electromagnet.

•

Auxiliary in alternating current. An inverter generates alternating current 110/230V 50Hz with continuous

current (duty cycle 100%) of 1.8 kVA/ 2.5 kVA

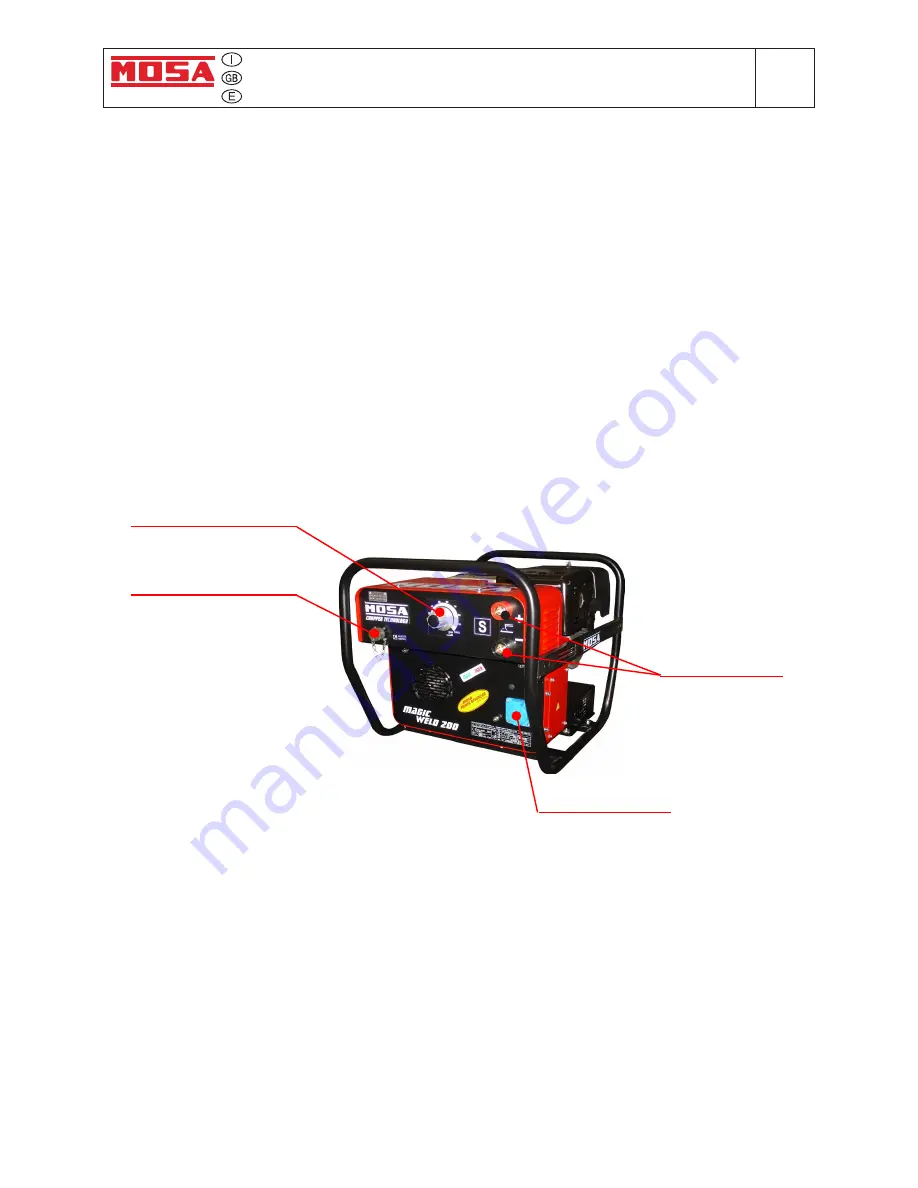

Auxiliary output

Welding sockets

Regulation knob for

welding current

MAGIC WELD 200

Remote control socket