CR60639B Hand Crimp Tool for “Min-Fit Jr.” Terminals

Doc No. 11-01-0198

Release Date: 04-08-93

UNCONTROLLED COPY

Page 2 of 5

Revision: E

Revision Date: 09-01-05

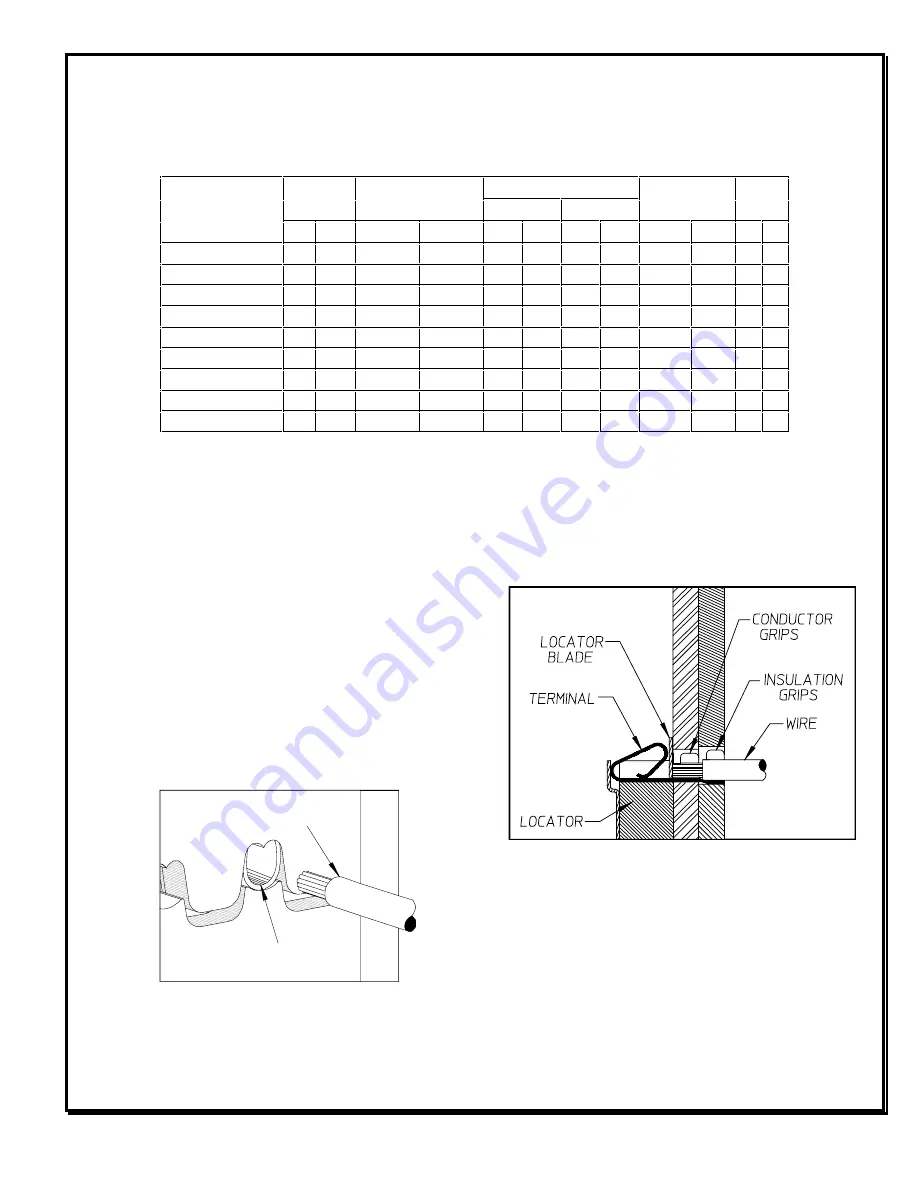

Figure 2

CONDITIONS:

After crimping, the conductor profiles should measure the following (see notes on page 4).

Punch Width (Ref)

Wire Size

Cond. Crimp Height

(Ref)

Cond. Ins.

Pull Force Min. Profile

Terminal Series No.

AWG mm

2

mm

In. mm

In.

mm

In. N Lb. A

B

5556-T2

22 0.35 0.76-0.86 .030-.034 1.42 .056 1.68 .066 40.0 9.00 X

5556-T2

24 0.20 0.69-0.79 .027-.031 1.42 .056 1.68 .066 31.1 7.00 X

5556-T2

26 0.12 0.64-0.74 .025-.029 1.42 .056 1.68 .066 22.2 5.00 X

5556-T2

28 0.08 0.61-0.71 .024-.028 1.42 .056 1.68 .066 13.3 3.00 X

5558-T2

22 0.35 0.76-0.86 .030-.034 1.42 .056 1.68 .066 40.0 9.00 X

5558-T2

24 0.20 0.69-0.79 .027-.031 1.42 .056 1.68 .066 31.1 7.00 X

5558-T2

26 0.12 0.64-0.74 .025-.029 1.42 .056 1.68 .066 22.2 5.00 X

5558-T2

28 0.08 0.61-0.71 .024-.028 1.42 .056 1.68 .066 13.3 3.00 X

OPERATION

Open the tool by squeezing the handles together, at the end of the closing stroke, the ratchet mechanism will release the handles,

and the hand tool will spring open.

Crimping Terminals

1. Lift the locator blade and place the terminal into the correct die

profile (A or B), release the locator blade. Not all tools are

equipped with a locator or locator blade.

2. Partially close the tool until the terminal is held in place, (See

Figure 1). If the insulation diameter is too large to do this, then

place the insulation down into the terminal before closing the

tool.

TERMINAL

PRE-STRIPPED WIRE

Figure 1