Distributor of Molex Connector Corporation: Excellent Integrated System Limited

Datasheet of 0640054100 - AT-FIFG CRIMP TOOL HEAD

Contact us: [email protected] Website: www.integrated-circuit.com

AT-FIFG Air Head Crimp Tool

Doc No. 64005-4100 Release Date: 09-22-03

UNCONTROLLED COPY

Page 2 of 6

Revision: A

Revision Date: 09-22-03

TERMINA

WIRE

CONDUCTO

R

Figure 3

CONDUCTO

R

WIRE

TERMINAL

Figure 2

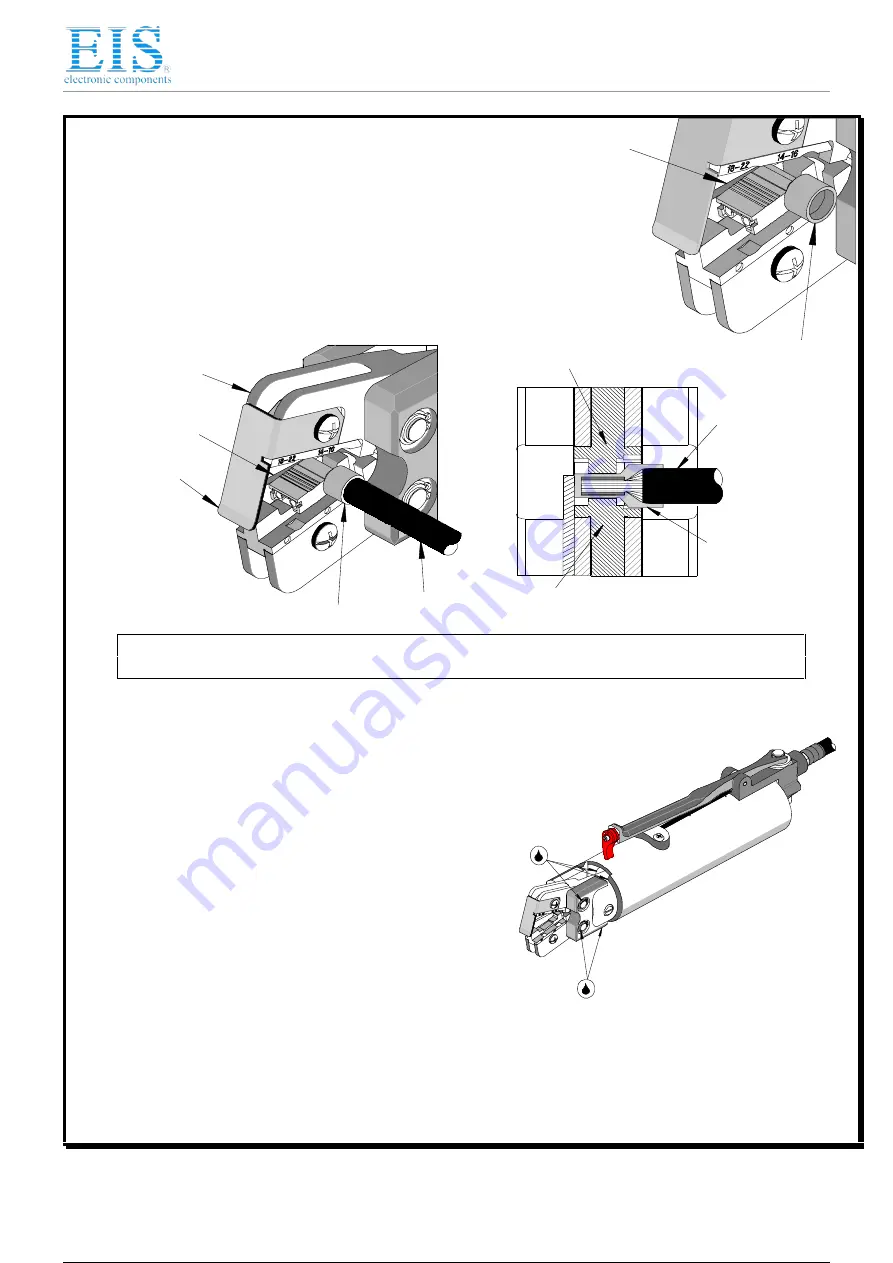

JAWS

OPEN

SAFETY

SHIELD

LOCATOR

Operation

Refer to the instruction manual for the 19279-0001 (AT-200) for

mounting this crimp tool head.

Crimping Terminals

1. Place the flag terminal barrel into the conductor anvil of the

lower jaw. Make sure the closed end of the barrel is touching

the locator. (See Figure 1).

Caution: Never operate this tool without the supplied safety shield in place. Never place

fingers in the tool nests.

2. Insert the properly stripped wire into the terminal barrel, (See figure 3).

3. Push on the wire to assure it is fully seated in the terminal (See Figure 2 and 3). Cycle the tool.

4. Remove the crimped terminal. Inspect for proper

crimp.

Maintenance

It is recommended that each operator of the tool be made

aware of, and responsible for, the following maintenance

steps:

1.

Remove dust, moisture and other contaminants with a

clean brush, or soft, lint-free cloth.

2.

Do not use any abrasive materials that could damage

the tool.

3.

Make certain all pins; pivot points and bearing

surfaces are protected with a thin coat of high quality

machine oil. Do not oil excessively. The 64005-4100 (AT-FIFG) was engineered for durability, but

like any fine piece of equipment it needs cleaning and lubrication for a maximum service life of

trouble-free crimping. A light oil, such as 30 weight automotive oil used at the oil points shown in

Figure 4, every 5,000 crimps or monthly will significantly enhance the tool life and ensure a stable

calibration.

4.

When tool is not in use store the tool in a clean, dry area.

LUBRICATION

POINTS

(BOTH SIDES)

LIGHT OIL

Figure 4

Figure 1

LOCATO

TERMINA

3 / 7

3 / 7