Hand Crimp Tool for Nano-Fit™ Crimp Terminals

Doc No: ATS-6382760HM

Release Date: 10-17-14

UNCONTROLLED COPY

Page 2 of 7

Revision: A

Revision Date: 10-22-14

CRIMP SPECIFICATION

Terminal Series No.

Bell mouth

Cut-off Tab Maximum

Conductor Brush

mm

In.

mm

In.

mm

In.

105300

0.15 – 0.25 0.006 – 0.010

0.17

.007

0.25 – 1.00 0.010 – 0.039

Terminal Series No.

Bend up Bend down Twist Roll

Seam

Seam shall not be open

and no wire allowed out of

the crimping area

Degree

Degree

105300

3

3

4

8

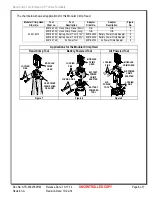

After crimping, the conductor profiles should measure the following.

Terminal

Series No

Wire Size

Conductor Crimp

Insulation Crimp

▲

Pull Force

Minimum

Profile

Height

Width (Ref.) Height (Ref) Width (Ref)

A B C D

AWG mm

2

mm

In.

mm

In.

mm

In.

mm In.

N

Lb. 24 24 26 26

105300

24

-

0.70 – 0.75 0.027 – 0.030 1.15 0.045

1.60 0.063 1.55 0.061

22.3 5

X

1.70 0.067 1.70 0.067

X

26

-

0.65 – 0.70 0.025 – 0.027 1.15 0.045

1.55 0.061 1.55 0.061

13.4 3

X

1.65 0.065 1.70 0.067

X

▲

To Achieve IPC-A-620 Class 2 Crimps, the following over-all wire insulation diameter ranges are recommended:

Profile A: (UL1061) 1.10mm – 1.20mm (0.043in – 0.047in)

Profile B: (UL1007) 1.30mm – 1.40mm (0.051in – 0.055in)

Profile C: (UL1061) 1.05mm – 1.15mm (0.041in – 0.045in)

Profile D: (UL1007) 1.20mm – 1.30mm (0.047in – 0.051in)

Tool Qualification Notes:

1.

Pull Force should be measured with no influence from the insulation crimp.

2.

The above specifications are guidelines to an optimum crimp.

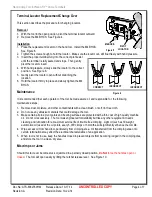

Notes:

1.

This tool should only be used for the terminals and wire gauges specified on this sheet.

2.

This tool is not adjustable for crimp height. Variations in tools, terminals, wire stranding, and insulation types

may affect crimp height.

3.

This tool is intended for standard conductor sizes. It may not give a good insulation crimp support for all

insulation sizes.

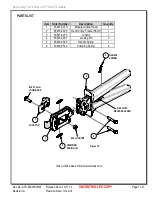

4.

Molex does not repair hand tools (see warranty above). The replacement parts listed are the only parts

available for repair. If the handles or crimp tooling is damaged or worn, a new tool must be purchased.

5.

Pull force should be used as the final criteria for an acceptable crimp. Pull force is measured with no

influence from the insulation crimp. The insulation should be stripped long (1/2 in.) so the insulation grips

on the terminal do not grip the wire insulation or the conductor. Refer to Molex Quality Crimping

Handbook 63800-0029 for additional information on crimping and crimp testing.

6.

Molex does not certify crimp hand tools.

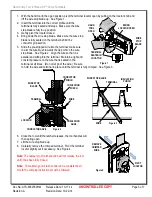

OPERATION

Open the tool by squeezing the handles together, at the end of the closing stroke, the ratchet mechanism will

release the handles, and the hand tool will spring open.