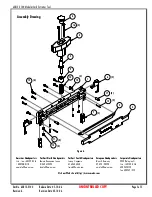

63813-2100 Modular Card Extractor Tool

Doc No. 63813-2100

Release Date: 05-10--06

UNCONTROLLED COPY

Page 2 of 5

Revision: A

Revision Date: 05-10-06

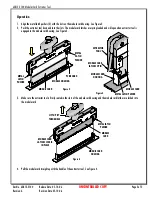

PCB BOARD

Figure 2

MODULE CARD

METAL

LATCH

PUSHER

METAL

LATCH

PUSHER

MODULE HOUSING

MODULE CARD

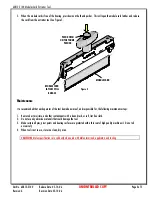

LATCHES OPEN

METAL LATCH PUSHER

Figure 3

MODULE CARD

MODULE CARD

HOUSING

EXTRACTOR

TOOL

MODULE CARD

HOUSING

Figure 4

METAL LATCH

PUSHER

MODULE

CARD

MODULE CARD

LATCHES LOCKED

IN PLACE

LIFT UP BY

THE HANDLE

Operation

1. Align the metal latch pushers (2) with the slots on the module card housing. See Figure 2.

2. Push the extractor tool down and into the slots. The module card latches are spring-loaded and will open when extractor tool is

engaged in the module card housing. See Figure 3.

3. Make sure the extractor tool is firmly seated in the slots of the module card housing and the module card latches are locked into

the module card.

4. Pull the module card straight up with the handle of the extractor tool. See Figure 4.