16

Plan Sheet 3 shows all the details for construct-

ing the basic fuselage. The plan also shows the

cross bracing wires for the fuselage and the alu-

minum cockpit cowl. However, do not install

the cockpit cowl or any brace wires that would

interfere with installing cockpit controls. The

cowl and some wires would get in the way

when installing cockpit controls, seats, etc. The

instrument panel fittings should be installed

during this stage, as it is easier to place these in

the instrument panel formers before the form-

ers are installed. The landing gear, remaining

cockpit controls, and engine installation will

also be discussed in later stages. The following

parts are required for this stage:

Laser-Cut Wood Parts

Forward instrument panel former – 1 of F1

Aft instrument panel former– 1 of F2

Turtleback formers – 1 each of F3 through

F10

Fuselage building jig center piece – 1 of F26

Fuselage building jig formers – 1 each of

F27 through F32

Britannia Castings

Oil pressure gauges – 2 of E1

Altimeters – 2 of E2

Ignition Switch – 1 of E3

Air speed indicator – 1 of E4

Tachometer – 1 of E5

Water temperature gauge – 1 of E6

Photo-Etched Copper Parts

Double eye cross brace wire fitting – 24

of F11

Triple eye cross brace wire fitting – 18

of F12

Strut clips Station 6 thru11 – 24 of F13

Nose plate front piece – 1 of F14

Nose plate side pieces – 2 of F15

Upper strut clip Station 2 – 2 of F16

Lower strut clip at Station 2 – 2 of F17

Upper strut clip at Station 3 – 2 of F18

Lower strut clip at Station 3 – 2 of F19

Upper strut clip at Station 4 & 5 – 4 of F20

Lower strut clip at Station 4 and 5 – 4 of F21

Step plate – 1 of F22

Single eye rig fitting – 32 of R1

Turnbuckles – 82 of R3A (short)

Steel Rod

Tail skid support rods – 1/32"-dia. rod

Wood Strips

(cut to length as required)

Turtleback stringers – 1/32" x 3/64"

Floor boards and shelf behind the rear

cockpit – 1/32" x 1/2"

Vertical and horizontal struts and vertical

longitudinal seat rail struts – 1/16" x 1/16"

STAGE 3:

BUILDING THE BASIC FUSELAGE

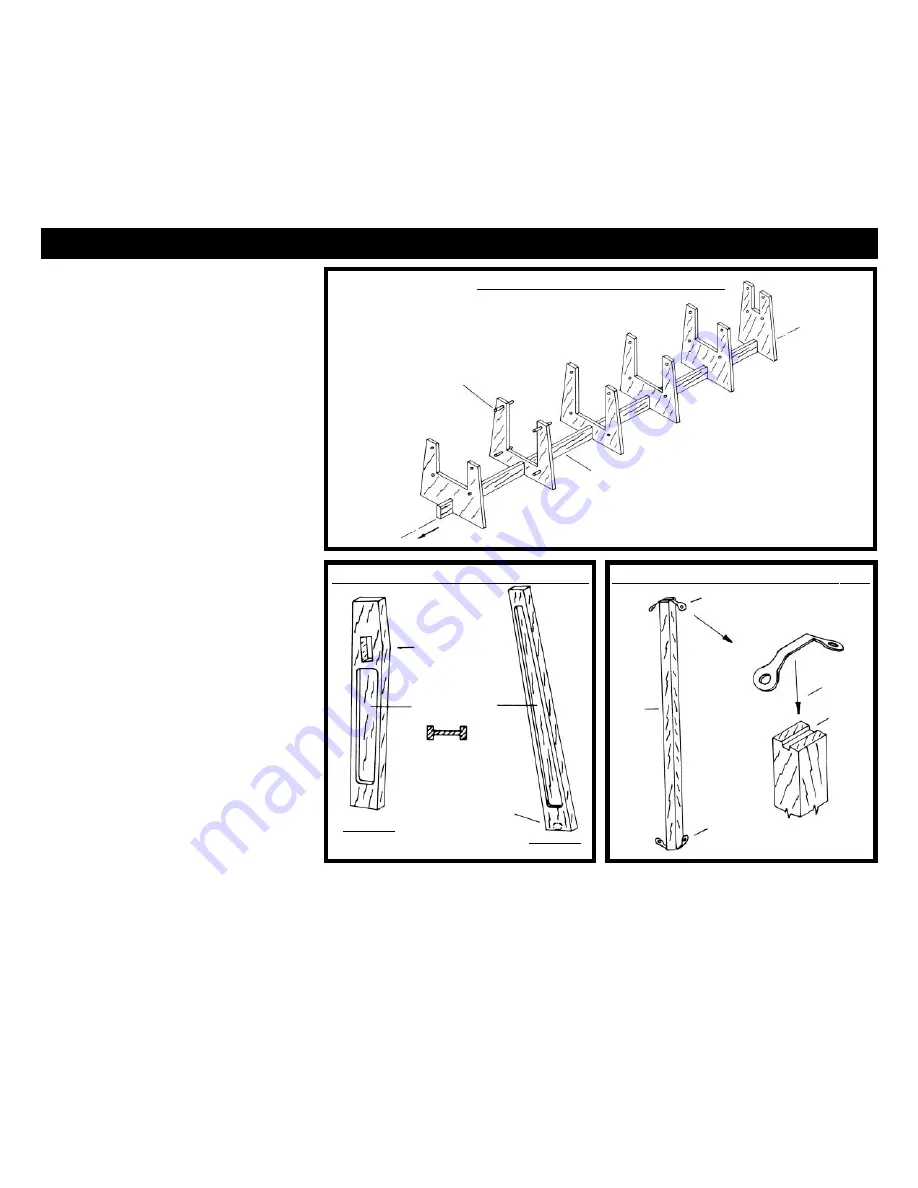

FIG. 3-1 FUSELAGE BUILDING JIG

F26 – CENTER PIECE

F27

TYPICAL 1/8"

DOWEL AT

EACH FORMER

F28

F29 – FORMERS

F30

F31

F32

FRONT

FIG. 3-3 STRUTS AT STATIONS 6 TO 11

1/16"

SQUARE

USE

SUPER

GLUE

FILE

GROOVE

F11

F11

top and bottom of the ribs like the stringers

of the wing ribs. These notches are not

laser-cut into the elevator ribs for fear the

rib may break between the upper and lower

notches before assembly.

After removing the elevator from the build-

ing board, add copper tape and the fittings

for the control cable brace wires (R2) at the

trailing edge in way of the ribs. Mount the

control horns (C2), then add the lower cap

strips to the ribs. Cut slots for the fake

hinges in the leading edge, then assemble

the elevator to the horizontal stabilizer using

brass strip as fake hinges.

Figure 2-4

illustrates the elevator assembly.

5. Mounting the Vertical Stabilizer

Now is a good time to mount the vertical

stabilizer on top of the horizontal stabilizer.

Simply glue this on top of the center hori-

zontal stabilizer rib cap strip. Make sure it

is vertical. On the real aircraft the vertical

stabilizer is bolted on.

You can install the brace wires at this time

using the 0.010" gray nylon cord. Short turn-

buckles (R3A) are located at the horizontal

stabilizer end.

Like the wings, store the completed tail sur-

faces and struts in a safe place until they are

ready to be installed on the fuselage.

FIG. 3-2 STRUTS AT STATIONS 3, 4 & 5

HOLE FOR

ENGINE BEARER

SUPPORT BEAM

STATION 3

STATION 4

(5 SIMILAR)

HOLE FOR FAKE LOWER

WING HINGES –

DRILL LATER TO

MATCH WING

MORTISE BOTH

SIDES

Longerons – 1/16" x 3/32"

Engine support beam – 3/32" x 3/16"

Engine bearers – 1/8" x 3/16"

Longitudinal and transverse seat rails

and strut between rails – 1/16" x 1/8"

Floor board supports, large vertical struts

(Stations 4 & 5) and tailpost – 1/16" x 3/16"

Large vertical struts (Station 3) – 1/16"

x 1/4"

Wood Dowels

(cut to length as required)

Fuselage building jig dowel pins –

1/8"-diameter

Rigging Cord

(cut to length as required)

Fuselage cross bracing wires – 0.010"-

diameter gray nylon cord

Wrapping cord for splices – 0.008"-diam-

eter black nylon cord

1. Building the Fuselage Jig

The fuselage sides can be assembled directly

on the plan like the wings. Then, the sides

will be transferred to a building jig. The jig

will hold the sides in the correct shape so the

top and bottom struts can be added, result-

ing in a correctly shaped fuselage.

Start by assembling the laser-cut building

jig. Assemble the jig on a rigid board like a

plywood board or particle board (not sup-

plied in the kit). First, draw a straight guide

line on the board. Tack or glue (or both) the

jig center piece (F26) to the board, using the

drawn line to get it straight. Next, insert a

1/2" long piece of 1/8" dowel through each of

the round holes in all the laser-cut formers