Slit damage Mechanical

Touching or contacting the slit substrates; for example,

attempting to clean the slit with a cotton swab, or

positioning a source such as an optical fiber, so that it

contacts the slit substrate

will

damage the slits.

Particle contamination results in plugged slits, and

most likely is due to operation in a high particulate

environment, or attempts to clean the slit.

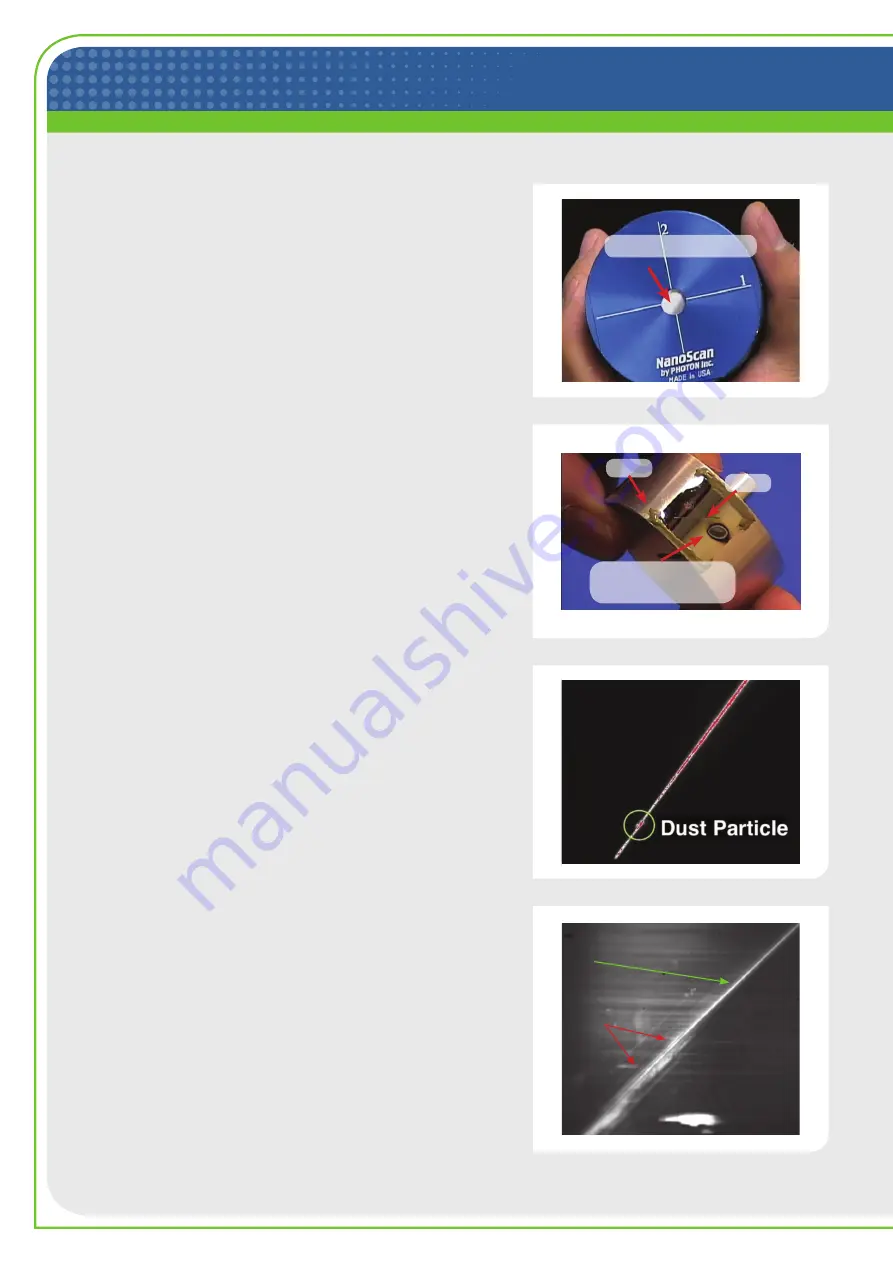

nanoScan aperture care

The air slit and pinhole aperture substrates are very thin

and extremely fragile. Any physical contact will likely

damage them. Treat the slits with care; because of their

fragility, never touch them with anything!

Debris such as dust particle can loge in the very fine

openings of the slits or pinholes and obstruct the

passage of the incident beam, especially in the 1.8 µm

slits. This can compromise instrument performance,

resulting in erroneous or inconsistent measurements.

With slits, a few dust particles may or may not be a

problem, depending on the application and measurement

configuration, while contamination by many particles is

more likely to create a problem. With pinhole apertures

a single particle can be disastrous. Therefore, when the

system is not is use, it is recommended that the protective

plastic cap be used to cover the scanhead entrance

aperture to avoid possible contamination. If inconsistent

performance is observed and contamination by debris is

suspected a clean jet of compressed gas may solve the

problem, but excessive pressure may also damage the

apertures. Do not under any circumstances attempt to

clean the apertures with solvents!

If aperture contamination is suspected, it is recommended

that the unit be returned to Ophir-Spiricon for aperture

inspection, cleaning or replacement, and recalibration.

Laser

Laser damage to slits is caused by CW beams with

excessive irradiance, pulsed beams with excessive peak

irradiance, pulsed beams with excessive fluence, and

long-term exposure to high average power CW or pulsed

beams.

Excessive Laser Irradiance Slit Damage

Do Not Touch Drum

Drum

Slit

Laser Burn Hole Due to

Drum Not Rotating

Slit

Laser Damage

Magnified Image