5

2-3. PRECAUTIONS WHEN REUSING EXISTING R22 REFRIGERANT PIPES

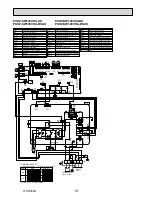

Flowchart

Perform the airtight test, vacuum air purging,

additional refrigerant charging (if necessary),

and gas leak check.

• Refer to the fl owchart below to determine if the existing pipes can be used and if it is necessary to use a fi lter dryer.

• If the diameter of the existing pipes is different from the specifi ed diameter, refer to technological data materials to confi rm if the pipes can be used.

Measure the existing pipe thickness and

check for damage.

The existing pipe thickness meets specifi ca-

tions and the pipes are not damaged.

Check if the existing outdoor unit can operate.

After operating the cooling system for about 30

minutes, do a pump down work.

Disconnect the existing outdoor unit from the

pipes.

Attach the new outdoor unit

Test run

* Refer to 10-2. TEST POINT UNDER TEST RUN.

The existing pipes cannot be reused.

Use new pipes.

* If the existing outdoor unit cannot operate, use

a refrigerant recovery device to collect the refrigerant.

Use new pipes for SW75, SW100 and SW120 models.

The existing pipe thickness does not meet

specifi cations or the pipes are damaged.

2-4. PRECAUTIONS FOR SALT PROOF TYPE "-BS" MODEL

Although "-BS" model has been designed to be resistant to salt damage, observe the following precautions to maintain the

performance of the unit.

1. Avoid installing the unit in a location where it will be exposed directly to seawater or sea breeze.

2. If the cover panel may become covered with salt, be sure to install the unit in a location where the salt will be washed away

by rainwater. (If a sunshade is installed, rainwater may not clean the panel.)

3. To ensure that water does not collect in the base of the outdoor unit, make sure that the base is level, not at angle. Water

collecting in the base of the outdoor unit could cause rust.

4. If the unit is installed in a coastal area, clean the unit with water regularly to remove any salt build-up.

5. If the unit is damaged during installation or maintenance, be sure to repair it.

6. Be sure to check the condition of the unit regularly.

7. Be sure to install the unit in a location with good drainage.

OCH533A