1

1

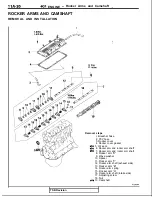

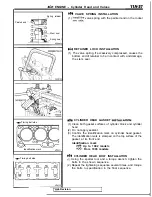

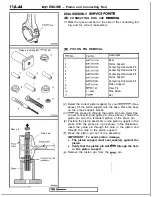

ENGINE Rocker Arms and Camshaft

Timing belt side

Wave washer

Bolt hole

center

1

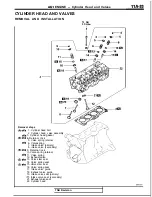

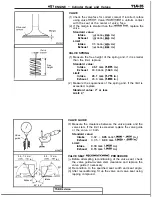

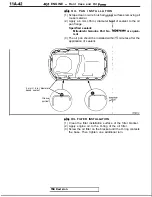

INSPECTION

CAMSHAFT

(1) Measure the cam height.

Standard value:

Intake

38.78

(1.5268 ‘in.)

Exhaust

3 9 . 1 0 m m

,

Limit:

Intake

38.28 mm (1.5071 in.)

Exhaust

38.60 mm (1.5197 in.)

ROCKER ARM

l

Check the roller surface. If any dents, damage or seizure is

evident, replace the rocker arm.

l

Check rotation of the roller. If it does not rotate smoothty or

if looseness is evident, replace the rocker arm.

l

Check the inside diameter. If damage or seizure is

replace the rocker arm.

l

Check the screw end for wear. If considerable wear is

evident, replace the adjusting screw.

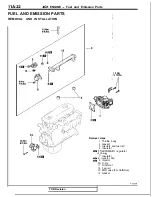

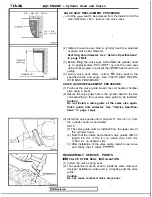

INSTALLATION SERVICE POINTS

CAMSHAFT INSTALLATION

Position the dowel pin of the camshaft as shown in the

illustration.

. .

ROCKER ARM AND ROCKER ARM SHAFT

INSTALLATION

(1)

the rocker arm shaft assembly

illustrated positions.

NOTE

Make sure that the bolt hole center is offset toward the

indicated side with respect to the rocker arm shaft

centerline.

OIL SEAL INSTALLATION

TSB Revision

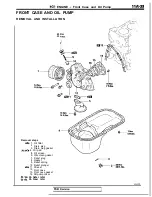

Summary of Contents for 4G1 series

Page 2: ......

Page 11: ...4Gl ENGINE General Information TSB Revision 1 ...

Page 12: ...VA 4 4Gl ENGINE General Information UBRICATION SYSTEM P 0 Z t7 ii ii I OTJ 09 1 TSB Revision ...

Page 21: ...4Gl ENGINE Special Tools Valve stem seal compressor Flywheel stopper 1 TSB Revision ...

Page 46: ...1 IA 38 461 ENGINE Cvlinder Head and Valves TSB Revision ...

Page 62: ...N O T E S ...

Page 65: ...4G3 ENGINE General Information pqJp3 I 3EN0087 TSB Revision ...

Page 66: ...IIB 4 4G3 ENGINE General Information JBRICATION SYSTEM 3LUOO20 TSB Revision ...

Page 77: ...463 ENGINE Special Tools Removal of crankshaft sprocket 1 TSB Revision ...

Page 106: ...11 B 44 4G3 ENGINE Cylinder Head and Valves 3EN018E TSB Revision ...

Page 127: ...4G6 ENGINE 1992 General Information 6EN0314 TSB Revision I ...

Page 128: ...IIC 4 466 ENGINE 1992 General Information NGlNE SECTIONAL VIEW DOHC TSB Revision ...

Page 129: ...6EN0244 TSB Revision ...

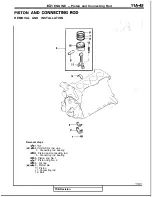

Page 225: ...4G6 ENGINE 1992 Piston and Connecting Rod 1 IC 101 TSB Revision ...

Page 232: ...NOTES ...

Page 235: ...4G9 ENGINE General Information llD 3 ru l 9EN0105 TSB Revision ...

Page 236: ...11D 4 4G9 ENGINE General Information UBRICATION SYSTEM 9EN0106 TSB Revision ...

Page 284: ...NOTES ...

Page 287: ...6G7 ENGINE General Information llE 3 TEN0324 1 Revision ...

Page 289: ...667 ENGINE General Information TSB Revision 7EN0120 I ...

Page 290: ...WE 6 6G7 ENGINE General Information SECTIONAL VIEW DOHC NON TURBO ENGINE TSB Revision 7EN0325 ...

Page 291: ......

Page 292: ...IIE 8 6G7 ENGINE General Information SECTIONAL VIEW DOHC TURBO ENGINE 1 TSB Revision 7EN0335 ...

Page 293: ...667 ENGINE General Information IIE 9 TSB Revision 7EN0334 ...

Page 409: ...4G6 ENGINE 1993 General Information TS8 Revision 6EN0630 ...

Page 411: ...466 ENGINE 1993 General Information 6EN0614 TSB Revision ...

Page 412: ...4G6 ENGINE 1993 General Information ENGINE SECTIONAL VIEW DOHC 6EN0619 TSB Revision ...

Page 413: ...4G6 ENGINE 1993 General Information I W7 6EN0620 TSB Revision ...

Page 522: ...NOTES ...