MODEL: WD-52327 / WD-62327

Page 26

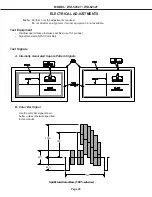

Activating & Selecting an Internal

Test Signal

1. Select an External Input with no signal.

2. Press the buttons “MENU”-“5”-“7”-“5”-“7” in

sequence. (Activates the Service Menu)

3. Select the “FPGA” function (AUDIO button)

4. Press “1” for Pattern A, or “2” for Pattern B.

5.

Press “9”

to return to the Service Menu.

6. Press “MENU” to exit the Service Mode.

.

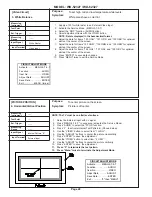

CAUTION

DO NOT

press

“MENU” (or HOME)

without

pressing

“9”

first. (The Video Mute function will

not function properly.)

To correct the Mute function

-- remove AC to

the TV, then reapply AC to reset the unit.

Summary of Contents for WD-52327

Page 2: ......

Page 11: ...MODEL WD 52327 WD 62327 Page 11 VK26 Chassis PWB Locations Shield Cover removed ...

Page 42: ...Page 42 MODEL WD 52327 WD 62327 ...

Page 43: ...MODEL WD 52327 WD 62327 Page 43 ...

Page 44: ...Page 44 MODEL WD 52327 WD 62327 ...

Page 45: ...MODEL WD 52327 WD 62327 Page 45 ...

Page 46: ...Page 46 MODEL WD 52327 WD 62327 ...

Page 47: ...MODEL WD 52327 WD 62327 Page 47 ...

Page 48: ...Page 48 MODEL WD 52327 WD 62327 ...

Page 49: ...MODEL WD 52327 WD 62327 Page 49 ...

Page 50: ...Page 50 MODEL WD 52327 WD 62327 ...

Page 51: ......