– 13 –

(2) Method of grease lubrication (replenishment)

The motors with open bearings and a grease over-stuffing

prevention structure are of either of the two configurations

below. Lubricate the motor of each configuration

according to the procedures below.

In each event, when removing the old grease and

charging the new, use care so as not to come into contact

with the rotating bodies such as the shaft.

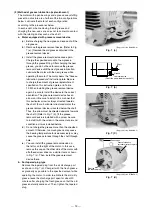

a. Motor equipped with grease removal device

(a) Before charging the new grease, dispose of all the

old grease.

(b) Remove the grease removal device. [Refer to Fig.

7 (a).] Remove the old grease contained in the

grease removal device.

(c) Install the grease removal device once again.

Charge the specified amount of new grease

through the grease fitting. After charging the new

grease, you do not have to remove the grease

removal device until the next grease lubrication.

Lubricate the motor with the new grease while

operating the motor. The motor bears the "Grease

lubrication procedure" instruction plate. Be sure

to charge the amount of grease replenishment

specified on this instruction plate or in Table

12. When installing the grease removal device

again, be sure to install the device to the correct

orientation. The grease removal device has an

arrow on it. Be sure to install it in a manner that

this particular arrow is always directed towards

the shaft. (For a horizontal structured motor, the

grease removal device is located below the shaft.

Thus, the arrow must be directed upwards towards

the shaft.) [Refer to Fig. 7 (b).] If the grease

removal device is installed with a screw, be sure

to install it with the screw in the same manner and

condition as it was installed before.

(d) Do not charge the grease more than the specified

amount. Otherwise, too much grease may cause

the bearing temperature to rise excessively or may

cause the grease to leak through the shaft through

hole.

(e) You can install the grease removal device on

the left or on the right of the motor. In this case,

remove the cap on the other side of the motor with

a flathead screw driver or a similar tool as shown

in Fig. 7 (c). Then, install the grease removal

device there.

b. For tapered plug type

Remove the tapered plug from the oil discharge port

as shown in Fig. 7 (d). Charge it with the fresh grease

as gradually as possible to the specified amount while

operating the motor. In order to eliminate the old, dirty

grease, leave the discharge port open for about 20

minutes after charging the fresh grease so that the old

grease naturally comes out. Then, tighten the tapered

plug.

(Nagoya Works B904138-9)

Fig. 7 (a)

(Nagoya Works B904138-5)

Fig. 7 (C)

Grease

removal device

(Direct the arrow towards the shaft.)

Shaft

Fig. 7 (b)

Grease gun

Remove

the tapered plug.

Grease lubrication

procedure instruction plate

(Nagoya Works B750058-5)

Fig. 7 (d)