MPI -

On-vehicle Service

13A-137

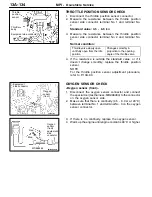

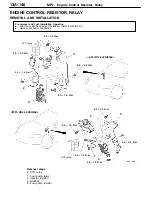

MB991607

High-pressure fuel hose

MD998741

MD998706

Return hose

Battery

Injector

Fuel pressure regulator

Clip

(MB991608)

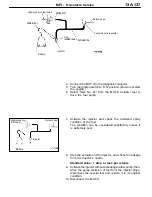

4. Connect the MUT-

II

to the diagnosis connector.

5. Turn the ignition switch to “ON” position. (But do not start

the engine.)

6. Select “Item No. 07” from the MUT-

II

Actuator test to

drive the fuel pump.

7. Activate the injector and check the atomized spray

condition of the fuel.

The condition can be considered satisfactory unless it

is extremely poor.

8. Stop the actuation of the injector, and check for leakage

from the injector’s nozzle.

Standard value: 1 drop or less per minute

9. Activate the injector without activating the fuel pump; then,

when the spray emission of fuel from the injector stops,

disconnect the special tool and restore it to its original

condition.

10. Disconnect the MUT-

II

.

High-pressure

fuel hose

Battery

Injector

Return hose

Summary of Contents for Lancer Evolution-VII

Page 1: ...WORKSHOP MANUAL EVOLUTION VII Pub No S0105CT9A ...

Page 2: ...G 1 WIRING AND PIPING DIAGRAM CONTENTS WIRING AND PIPING DIAGRAM 2 ...

Page 8: ...E 1 SYNTHETIC RESIN PARTS CONTENTS LOCATION OF SYNTHETIC RESIN PARTS 2 ...

Page 11: ...NOTES ...

Page 14: ...CORROSION PROTECTION Body Sealing Locations 1 2 3 4 5 6 7 8 D 3 ...

Page 17: ...NOTES ...

Page 19: ...C 2 NOTES ...

Page 44: ...BODY DIMENSIONS Body Dimensions and Measurement Methods B 3 NOTES ...

Page 59: ...NOTES ...

Page 85: ...NOTES ...

Page 158: ...B 53 NOTES ...

Page 159: ...CIRCUIT DIAGRAMS B 54 CIRCUIT DIAGRAMS J B H1J00X08AA ...

Page 161: ...CIRCUIT DIAGRAMS H1J00X06AA B 56 J C L H drive vehicles ...

Page 162: ...CIRCUIT DIAGRAMS H1J00X06AB B 57 ...

Page 163: ...CIRCUIT DIAGRAMS H1J00X06BA B 58 J C L H drive vehicles CONTINUED ...

Page 164: ...CIRCUIT DIAGRAMS H1J00X06BB B 59 ...

Page 165: ...CIRCUIT DIAGRAMS H1J00X06CA B 60 J C L H drive vehicles CONTINUED ...

Page 166: ...CIRCUIT DIAGRAMS H1J00X06CB B 61 ...

Page 167: ...CIRCUIT DIAGRAMS H1J00X09AA B 62 J C R H drive vehicles ...

Page 168: ...CIRCUIT DIAGRAMS H1J00X09AB B 63 ...

Page 169: ...CIRCUIT DIAGRAMS H1J00X09BA B 64 J C R H drive vehicles CONTINUED ...

Page 170: ...CIRCUIT DIAGRAMS H1J00X09BB B 65 ...

Page 171: ...CIRCUIT DIAGRAMS H1J00X09CA B 66 J C R H drive vehicles CONTINUED ...

Page 172: ...CIRCUIT DIAGRAMS H1J00X09CB B 67 ...

Page 177: ...CIRCUIT DIAGRAMS B 72 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 ...

Page 179: ...CIRCUIT DIAGRAMS H1J01X08AA B 74 POWER DISTRIBUTION SYSTEM ...

Page 180: ...CIRCUIT DIAGRAMS H1J01X08AB B 75 ...

Page 181: ...CIRCUIT DIAGRAMS H1J01X08BA B 76 POWER DISTRIBUTION SYSTEM CONTINUED ...

Page 182: ...CIRCUIT DIAGRAMS H1J01X08BB B 77 ...

Page 183: ...CIRCUIT DIAGRAMS H1J01X08CA B 78 POWER DISTRIBUTION SYSTEM CONTINUED ...

Page 184: ...CIRCUIT DIAGRAMS H1J02X06AA B 79 STARTING SYSTEM ...

Page 186: ...CIRCUIT DIAGRAMS B 81 NOTES ...

Page 187: ...CIRCUIT DIAGRAMS H1J03X08AA B 82 IGNITION SYSTEM L H drive vehicles ...

Page 188: ...CIRCUIT DIAGRAMS H1J03X07AA B 83 IGNITION SYSTEM R H drive vehicles ...

Page 189: ...CIRCUIT DIAGRAMS H1J04X04AA B 84 CHARGING SYSTEM ...

Page 191: ...CIRCUIT DIAGRAMS B 86 ENGINE CONTROL SYSTEM L H drive vehicles ...

Page 192: ...CIRCUIT DIAGRAMS H1J05X17AB B 87 ...

Page 193: ...CIRCUIT DIAGRAMS B 88 ENGINE CONTROL SYSTEM L H drive vehicles CONTINUED ...

Page 194: ...CIRCUIT DIAGRAMS B 89 ...

Page 195: ...CIRCUIT DIAGRAMS B 90 ENGINE CONTROL SYSTEM L H drive vehicles CONTINUED ...

Page 196: ...CIRCUIT DIAGRAMS B 91 ...

Page 197: ...CIRCUIT DIAGRAMS B 92 ENGINE CONTROL SYSTEM L H drive vehicles CONTINUED ...

Page 198: ...CIRCUIT DIAGRAMS H1J05X17DB B 93 ...

Page 199: ...CIRCUIT DIAGRAMS B 94 ENGINE CONTROL SYSTEM R H drive vehicles ...

Page 200: ...CIRCUIT DIAGRAMS B 95 ...

Page 201: ...CIRCUIT DIAGRAMS B 96 ENGINE CONTROL SYSTEM R H drive vehicles CONTINUED ...

Page 202: ...CIRCUIT DIAGRAMS B 97 ...

Page 203: ...CIRCUIT DIAGRAMS B 98 ENGINE CONTROL SYSTEM R H drive vehicles CONTINUED ...

Page 204: ...CIRCUIT DIAGRAMS B 99 ...

Page 205: ...CIRCUIT DIAGRAMS B 100 ENGINE CONTROL SYSTEM R H drive vehicles CONTINUED ...

Page 206: ...CIRCUIT DIAGRAMS H1J05X16DB B 101 ...

Page 207: ...CIRCUIT DIAGRAMS H1J06X03AA B 102 COOLING SYSTEM ...

Page 208: ...CIRCUIT DIAGRAMS H1J08X20AA B 103 HEADLAMP L H drive vehicles ...

Page 209: ...CIRCUIT DIAGRAMS B 104 HEADLAMP L H drive vehicles CONTINUED ...

Page 210: ...CIRCUIT DIAGRAMS B 105 ...

Page 211: ...CIRCUIT DIAGRAMS H1J08X19AA B 106 HEADLAMP R H drive vehicles ...

Page 212: ...CIRCUIT DIAGRAMS H1J08X19AB B 107 ...

Page 213: ...CIRCUIT DIAGRAMS H1J08X19BA B 108 HEADLAMP R H drive vehicles CONTINUED ...

Page 214: ...CIRCUIT DIAGRAMS B 109 NOTES ...

Page 216: ...CIRCUIT DIAGRAMS H1J08X23AB B 111 ...

Page 218: ...CIRCUIT DIAGRAMS H1J08X23BB B 113 ...

Page 220: ...CIRCUIT DIAGRAMS H1J08X21AB B 115 ...

Page 222: ...CIRCUIT DIAGRAMS H1J08X21BB B 117 ...

Page 223: ...CIRCUIT DIAGRAMS H1J08X26AA B 118 ROOM LAMP AND LUGGAGE COMPARTMENT LAMP L H drive vehicles ...

Page 224: ...CIRCUIT DIAGRAMS H1J08X26AB B 119 ...

Page 226: ...CIRCUIT DIAGRAMS H1J08X24AA B 121 ROOM LAMP AND LUGGAGE COMPARTMENT LAMP R H drive vehicles ...

Page 228: ...CIRCUIT DIAGRAMS H1J08X24BB B 123 ...

Page 229: ...CIRCUIT DIAGRAMS H1J08X28AA B 124 REAR FOG LAMP L H drive vehicles ...

Page 230: ...CIRCUIT DIAGRAMS H1J08X28AB B 125 ...

Page 231: ...CIRCUIT DIAGRAMS H1J08X28BA B 126 REAR FOG LAMP L H drive vehicles CONTINUED ...

Page 232: ...CIRCUIT DIAGRAMS H1J08X29AA B 127 REAR FOG LAMP R H drive vehicles ...

Page 233: ...CIRCUIT DIAGRAMS B 128 REAR FOG LAMP R H drive vehicles CONTINUED ...

Page 234: ...CIRCUIT DIAGRAMS B 129 ...

Page 235: ...CIRCUIT DIAGRAMS B 130 HEADLAMP LEVELING SYSTEM L H drive vehicles ...

Page 236: ...CIRCUIT DIAGRAMS B 131 ...

Page 237: ...CIRCUIT DIAGRAMS B 132 HEADLAMP LEVELING SYSTEM R H drive vehicles ...

Page 238: ...CIRCUIT DIAGRAMS B 133 ...

Page 239: ...CIRCUIT DIAGRAMS H1J09X15AA B 134 TURN SIGNAL LAMP AND HAZARD WARNING LAMP L H drive vehicles ...

Page 240: ...CIRCUIT DIAGRAMS H1J09X15AB B 135 ...

Page 242: ...CIRCUIT DIAGRAMS H1J09X15BB B 137 ...

Page 243: ...CIRCUIT DIAGRAMS H1J09X13AA B 138 TURN SIGNAL LAMP AND HAZARD WARNING LAMP R H drive vehicles ...

Page 244: ...CIRCUIT DIAGRAMS H1J09X13AB B 139 ...

Page 246: ...CIRCUIT DIAGRAMS H1J09X13BB B 141 ...

Page 247: ...CIRCUIT DIAGRAMS B 142 BACK UP LAMP L H drive vehicles ...

Page 248: ...CIRCUIT DIAGRAMS B 143 BACK UP LAMP R H drive vehicles ...

Page 249: ...CIRCUIT DIAGRAMS H1J09X17AA B 144 STOP LAMP L H drive vehicles ...

Page 250: ...CIRCUIT DIAGRAMS H1J09X18AA B 145 STOP LAMP R H drive vehicles ...

Page 251: ...CIRCUIT DIAGRAMS B 146 HORN ...

Page 253: ...CIRCUIT DIAGRAMS B 148 METER AND GAUGE L H drive vehicles ...

Page 254: ...CIRCUIT DIAGRAMS B 149 ...

Page 255: ...CIRCUIT DIAGRAMS H1J10X08BA B 150 METER AND GAUGE L H drive vehicles CONTINUED ...

Page 256: ...CIRCUIT DIAGRAMS B 151 NOTES ...

Page 257: ...CIRCUIT DIAGRAMS B 152 METER AND GAUGE R H drive vehicles ...

Page 258: ...CIRCUIT DIAGRAMS B 153 ...

Page 259: ...CIRCUIT DIAGRAMS H1J10X06BA B 154 METER AND GAUGE R H drive vehicles CONTINUED ...

Page 261: ...CIRCUIT DIAGRAMS H1J10X10AA B 156 FUEL WARNING LAMP ...

Page 262: ...CIRCUIT DIAGRAMS H1J10X10AB B 157 OIL PRESSURE WARNING LAMP BRAKE WARNING LAMP ...

Page 263: ...CIRCUIT DIAGRAMS H1J11X10AA B 158 POWER WINDOWS L H drive vehicles ...

Page 264: ...CIRCUIT DIAGRAMS H1J11X10AB B 159 ...

Page 265: ...CIRCUIT DIAGRAMS H1J11X10BA B 160 POWER WINDOWS L H drive vehicles CONTINUED ...

Page 266: ...CIRCUIT DIAGRAMS H1J11X10BB B 161 ...

Page 267: ...CIRCUIT DIAGRAMS H1J11X10CA B 162 POWER WINDOWS L H drive vehicles CONTINUED ...

Page 268: ...CIRCUIT DIAGRAMS H1J11X10CB B 163 ...

Page 269: ...CIRCUIT DIAGRAMS H1J11X14AA B 164 POWER WINDOWS R H drive vehicles ...

Page 270: ...CIRCUIT DIAGRAMS H1J11X14AB B 165 ...

Page 271: ...CIRCUIT DIAGRAMS H1J11X14BA B 166 POWER WINDOWS R H drive vehicles CONTINUED ...

Page 272: ...CIRCUIT DIAGRAMS H1J11X14BB B 167 ...

Page 273: ...CIRCUIT DIAGRAMS H1J11X14CA B 168 POWER WINDOWS R H drive vehicles CONTINUED ...

Page 274: ...CIRCUIT DIAGRAMS H1J11X14CB B 169 ...

Page 275: ...CIRCUIT DIAGRAMS H1J11X12AA B 170 CENTRAL DOOR LOCKING SYSTEM L H drive vehicles ...

Page 276: ...CIRCUIT DIAGRAMS H1J11X12AB B 171 ...

Page 277: ...CIRCUIT DIAGRAMS H1J11X15AA B 172 CENTRAL DOOR LOCKING SYSTEM R H drive vehicles ...

Page 278: ...CIRCUIT DIAGRAMS H1J11X15AB B 173 ...

Page 279: ...CIRCUIT DIAGRAMS B 174 HEATER AND MANUAL AIR CONDITIONER L H drive vehicles ...

Page 280: ...CIRCUIT DIAGRAMS B 175 ...

Page 281: ...CIRCUIT DIAGRAMS B 176 HEATER AND MANUAL AIR CONDITIONER L H drive vehicles CONTINUED ...

Page 282: ...CIRCUIT DIAGRAMS B 177 ...

Page 283: ...CIRCUIT DIAGRAMS B 178 HEATER AND MANUAL AIR CONDITIONER L H drive vehicles CONTINUED ...

Page 285: ...CIRCUIT DIAGRAMS B 180 HEATER AND MANUAL AIR CONDITIONER R H drive vehicles ...

Page 286: ...CIRCUIT DIAGRAMS B 181 ...

Page 287: ...CIRCUIT DIAGRAMS B 182 HEATER AND MANUAL AIR CONDITIONER R H drive vehicles CONTINUED ...

Page 288: ...CIRCUIT DIAGRAMS B 183 ...

Page 289: ...CIRCUIT DIAGRAMS B 184 HEATER AND MANUAL AIR CONDITIONER R H drive vehicles CONTINUED ...

Page 290: ...CIRCUIT DIAGRAMS H1J13X19AA B 185 DEFOGGER ...

Page 291: ...CIRCUIT DIAGRAMS B 186 WINDSHIELD WIPER AND WASHER L H drive vehicles ...

Page 292: ...CIRCUIT DIAGRAMS B 187 ...

Page 293: ...CIRCUIT DIAGRAMS H1J13X17BA B 188 WINDSHIELD WIPER AND WASHER L H drive vehicles CONTINUED ...

Page 294: ...CIRCUIT DIAGRAMS H1J13X16AA B 189 WINDSHIELD WIPER AND WASHER R H drive vehicles ...

Page 295: ...CIRCUIT DIAGRAMS B 190 WINDSHIELD WIPER AND WASHER R H drive vehicles CONTINUED ...

Page 296: ...CIRCUIT DIAGRAMS B 191 ...

Page 297: ...CIRCUIT DIAGRAMS H1J13X22AA B 192 REMOTE CONTROLLED MIRROR L H drive vehicles ...

Page 298: ...CIRCUIT DIAGRAMS H1J13X21AA B 193 REMOTE CONTROLLED MIRROR R H drive vehicles ...

Page 299: ...CIRCUIT DIAGRAMS H1J14X12AA B 194 CLOCK ...

Page 300: ...CIRCUIT DIAGRAMS H1J14X13AA B 195 CIGARETTE LIGHTER AND ASHTRAY ILLUMINATION LAMP ...

Page 301: ...CIRCUIT DIAGRAMS B 196 AUDIO SYSTEM ...

Page 302: ...CIRCUIT DIAGRAMS B 197 ...

Page 303: ...CIRCUIT DIAGRAMS B 198 ABS L H drive vehicles ...

Page 304: ...CIRCUIT DIAGRAMS B 199 ...

Page 305: ...CIRCUIT DIAGRAMS B 200 ABS L H drive vehicles CONTINUED ...

Page 306: ...CIRCUIT DIAGRAMS B 201 ...

Page 307: ...CIRCUIT DIAGRAMS H1J15X28CA B 202 ABS L H drive vehicles CONTINUED ...

Page 308: ...CIRCUIT DIAGRAMS H1J15X28CB B 203 ...

Page 309: ...CIRCUIT DIAGRAMS B 204 ABS L H drive vehicles CONTINUED ...

Page 310: ...CIRCUIT DIAGRAMS B 205 ABS R H drive vehicles ...

Page 311: ...CIRCUIT DIAGRAMS B 206 ABS R H drive vehicles CONTINUED ...

Page 312: ...CIRCUIT DIAGRAMS B 207 ...

Page 313: ...CIRCUIT DIAGRAMS B 208 ABS R H drive vehicles CONTINUED ...

Page 314: ...CIRCUIT DIAGRAMS B 209 ...

Page 315: ...CIRCUIT DIAGRAMS H1J15X42DA B 210 ABS R H drive vehicles CONTINUED ...

Page 316: ...CIRCUIT DIAGRAMS H1J15X42DB B 211 ...

Page 317: ...CIRCUIT DIAGRAMS B 212 ACD Vehicles without AYC L H drive vehicles ...

Page 318: ...CIRCUIT DIAGRAMS B 213 ...

Page 319: ...CIRCUIT DIAGRAMS B 214 ACD Vehicles without AYC L H drive vehicles CONTINUED ...

Page 320: ...CIRCUIT DIAGRAMS B 215 ...

Page 321: ...CIRCUIT DIAGRAMS B 216 ACD Vehicles without AYC L H drive vehicles CONTINUED ...

Page 322: ...CIRCUIT DIAGRAMS H1J15X30CB B 217 ...

Page 323: ...CIRCUIT DIAGRAMS H1J15X30DA B 218 ACD Vehicles without AYC L H drive vehicles CONTINUED ...

Page 324: ...CIRCUIT DIAGRAMS H1J15X30DB B 219 ...

Page 325: ...CIRCUIT DIAGRAMS B 220 ACD Vehicles without AYC R H drive vehicles ...

Page 326: ...CIRCUIT DIAGRAMS B 221 ...

Page 327: ...CIRCUIT DIAGRAMS B 222 ACD Vehicles without AYC R H drive vehicles CONTINUED ...

Page 328: ...CIRCUIT DIAGRAMS B 223 ...

Page 329: ...CIRCUIT DIAGRAMS B 224 ACD Vehicles without AYC R H drive vehicles CONTINUED ...

Page 330: ...CIRCUIT DIAGRAMS B 225 ...

Page 331: ...CIRCUIT DIAGRAMS H1J15X43DA B 226 ACD Vehicles without AYC R H drive vehicles CONTINUED ...

Page 332: ...CIRCUIT DIAGRAMS H1J15X43DB B 227 ...

Page 333: ...CIRCUIT DIAGRAMS B 228 ACD AND AYC L H drive vehicles ...

Page 334: ...CIRCUIT DIAGRAMS B 229 ...

Page 335: ...CIRCUIT DIAGRAMS B 230 ACD AND AYC L H drive vehicles CONTINUED ...

Page 336: ...CIRCUIT DIAGRAMS B 231 ...

Page 337: ...CIRCUIT DIAGRAMS H1J15X32CA B 232 ACD AND AYC L H drive vehicles CONTINUED ...

Page 338: ...CIRCUIT DIAGRAMS H1J15X32CB B 233 ...

Page 339: ...CIRCUIT DIAGRAMS H1J15X32DA B 234 ACD AND AYC L H drive vehicles CONTINUED ...

Page 340: ...CIRCUIT DIAGRAMS H1J15X32DB B 235 ...

Page 341: ...CIRCUIT DIAGRAMS B 236 ACD AND AYC L H drive vehicles CONTINUED ...

Page 342: ...CIRCUIT DIAGRAMS B 237 ...

Page 343: ...CIRCUIT DIAGRAMS B 238 ACD AND AYC R H drive vehicles ...

Page 344: ...CIRCUIT DIAGRAMS B 239 ...

Page 345: ...CIRCUIT DIAGRAMS B 240 ACD AND AYC R H drive vehicles CONTINUED ...

Page 346: ...CIRCUIT DIAGRAMS B 241 ...

Page 347: ...CIRCUIT DIAGRAMS H1J15X44CA B 242 ACD AND AYC R H drive vehicles CONTINUED ...

Page 348: ...CIRCUIT DIAGRAMS H1J15X44CB B 243 ...

Page 349: ...CIRCUIT DIAGRAMS H1J15X44DA B 244 ACD AND AYC R H drive vehicles CONTINUED ...

Page 350: ...CIRCUIT DIAGRAMS H1J15X44DB B 245 ...

Page 351: ...CIRCUIT DIAGRAMS B 246 ACD AND AYC R H drive vehicles CONTINUED ...

Page 352: ...CIRCUIT DIAGRAMS B 247 ...

Page 354: ...CIRCUIT DIAGRAMS B 249 ...

Page 356: ...CIRCUIT DIAGRAMS B 251 ...

Page 357: ...CIRCUIT DIAGRAMS H1J15X26AA B 252 IMMOBILIZER SYSTEM L H drive vehicles ...

Page 358: ...CIRCUIT DIAGRAMS H1J15X26AB B 253 ...

Page 359: ...CIRCUIT DIAGRAMS H1J15X25AA B 254 IMMOBILIZER SYSTEM R H drive vehicles ...

Page 360: ...CIRCUIT DIAGRAMS H1J15X25AB B 255 ...

Page 361: ...CIRCUIT DIAGRAMS B 256 INTERCOOLER WATER SPLAY ...

Page 362: ...CIRCUIT DIAGRAMS B 257 ...

Page 363: ...CIRCUIT DIAGRAMS H1J15X47AA B 258 SPARE CONNECTOR FOR FRONT FOG LAMP ...

Page 376: ...ELECTRICAL WIRING CONTENTS HOW TO READ THE WIRING DIAGRAMS A ELECTRICAL WIRING B INDEX C ...

Page 377: ...NOTES ...

Page 423: ...NOTES ...

Page 424: ...CHASSIS ELECTRICAL 54A SMART WIRING SYSTEM SWS 54B 54A 1 CHASSIS ELECTRICAL CONTENTS ...

Page 467: ...NOTES ...

Page 505: ...NOTES ...

Page 607: ...NOTES ...

Page 633: ...NOTES ...

Page 677: ...NOTES ...

Page 711: ...NOTES ...

Page 720: ...BASIC BRAKE SYSTEM 35A ANTI SKID BRAKING SYSTEM ABS 4WD 35B 35A 1 SERVICE BRAKES CONTENTS ...

Page 783: ...NOTES ...

Page 799: ...NOTES ...

Page 811: ...NOTES ...

Page 897: ...NOTES ...

Page 908: ...MANUAL TRANSMISSION 22A MANUAL TRANSMISSION OVERHAUL 22B 22A 1 MANUAL TRANSMISSION CONTENTS ...

Page 965: ...NOTES ...

Page 968: ...MANUAL TRANSMISSION OVERHAUL General Description 22B 3 SECTIONAL VIEW W5M51 2 X5B1 ...

Page 969: ...MANUAL TRANSMISSION OVERHAUL General Description 22B 4 SECTIONAL VIEW W5M51 2 X5B2 ...

Page 970: ...MANUAL TRANSMISSION OVERHAUL General Description 22B 5 SECTIONAL VIEW W5M51 2 X5B X5B4 ...

Page 1018: ...CLUTCH 21A CLUTCH OVERHAUL 21B 21A 1 CLUTCH CONTENTS ...

Page 1027: ...NOTES ...

Page 1035: ...NOTES ...

Page 1055: ...NOTES ...

Page 1093: ...NOTES ...

Page 1137: ...NOTES ...

Page 1138: ...13A 1 FUEL CONTENTS MULTIPOINT FUEL INJECTION MPI 13A FUEL SUPPLY 13B ...

Page 1285: ...NOTES ...

Page 1286: ...13B 1 FUEL SUPPLY CONTENTS GENERAL INFORMATION 2 ON VEHICLE SERVICE 2 FUEL TANK 3 ...

Page 1301: ...NOTES ...

Page 1302: ...ENGINE 11A ENGINE OVERHAUL 11B 11A 1 ENGINE CONTENTS ...

Page 1349: ...NOTES ...

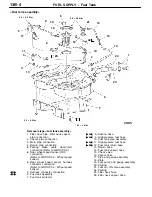

Page 1419: ...NOTES ...