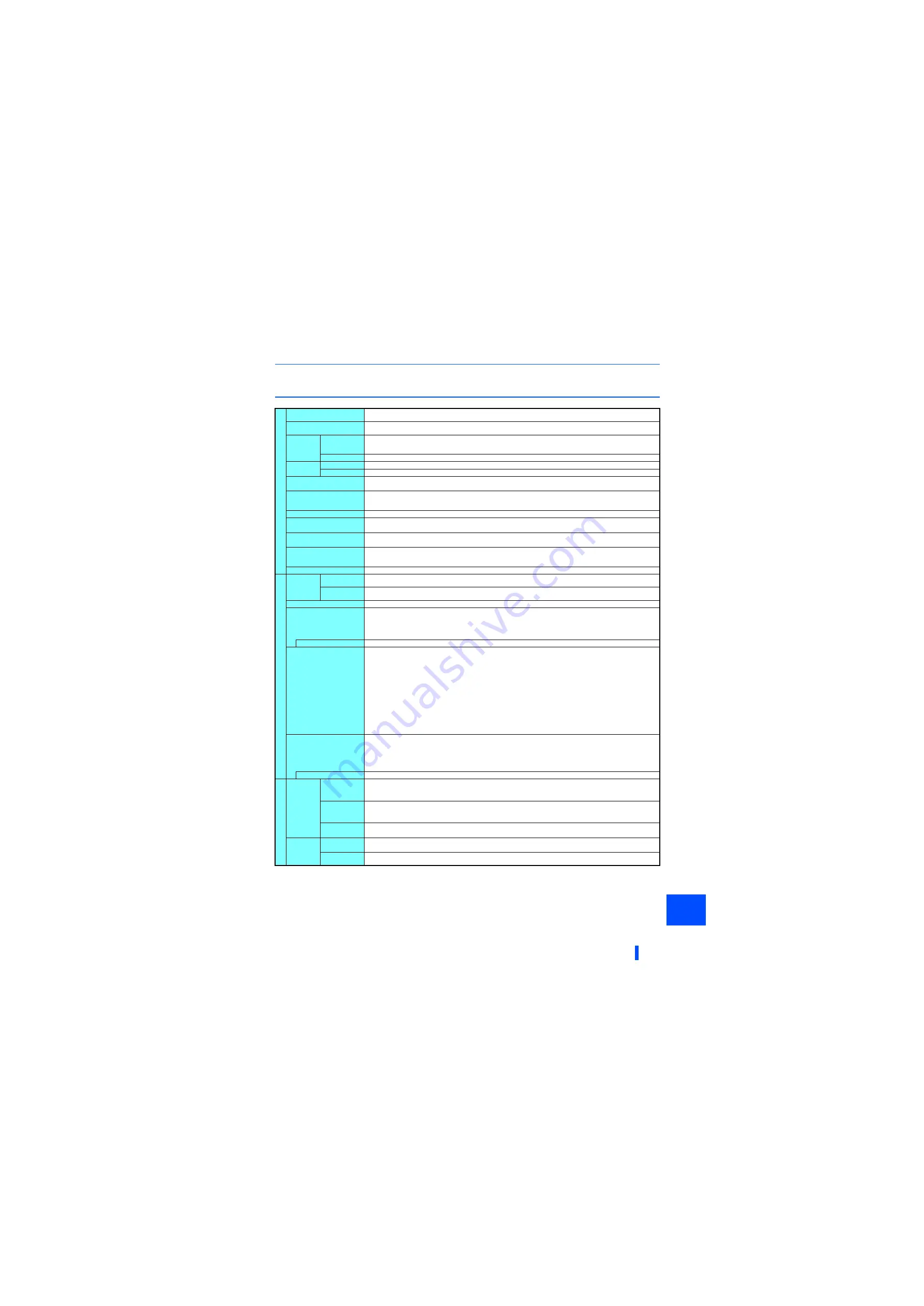

Common specifications

111

6

6.2

Common specifications

C

o

nt

ro

l s

p

e

ci

fi

ca

ti

on

s

Control method

Soft-PWM control, high carrier frequency PWM control (selectable among V/F control, Advanced magnetic flux vector

control, Real sensorless vector control), Optimum excitation control, and vector control

Output frequency range

0.2 to 590 Hz (The upper frequency limit is 400 Hz (200 Hz for the SND rating) under Advanced magnetic flux vector

control, Real sensorless vector control, and vector control

Frequency

setting

resolution

Analog input

0.015 Hz/60 Hz (terminal 2, 4: 0 to 10 V/12 bits)

0.03 Hz/60 Hz (0 to 5 V/11 bits or 0 to 20 mA/approx. 11 bits for terminals 2 and 4, 0 to

±

10 V/12 bits for terminal 1)

0.06 Hz/60 Hz (0 to

±

5 V/11 bits for terminal 1)

Digital input

0.01 Hz

Frequency

accuracy

Analog input

Within

±

0.2% of the max. output frequency (25°C

±

10°C)

Digital input

Within 0.01% of the set output frequency

Voltage/frequency

characteristics

Base frequency can be set from 0 to 590 Hz. Constant-torque/variable-torque pattern can be selected.

Starting torque

SLD rating: 120% 0.3 Hz, LD rating: 150% 0.3 Hz, SND rating: 150% 0.3 Hz, ND rating: 200%

0.3 Hz

(under Real sensorless vector control or vector control

Torque boost

Manual torque boost

Acceleration/deceleration

time setting

0 to 3600 s (acceleration and deceleration can be set individually), linear or S-pattern acceleration/deceleration mode,

backlash countermeasures acceleration/deceleration can be selected.

DC injection brake

(induction motor)

Operation frequency (0 to 120 Hz), operation time (0 to 10 s), operation voltage (0 to 30%) variable

Stall prevention operation

level

Activation range of stall prevention operation (SLD rating: 0 to 120%, LD rating: 0 to 150%, SND rating: 0 to 220%, ND

rating: 0 to 220%, HD rating: 0 to 280%). Whether to use the stall prevention or not can be selected. (V/F control,

Advanced magnetic flux vector control)

Torque limit level

Torque limit value can be set (0 to 400% variable). (Real sensorless vector control, vector control

)

Oper

at

ion

spe

c

if

ic

at

ions

Frequency

setting

signal

Analog input

Terminals 2 and 4: 0 to 10 V, 0 to 5 V, 4 to 20 mA (0 to 20 mA) are available.

Terminal 1: -10 to +10 V, -5 to 5 V are available.

Digital input

Input using the setting dial of the operation panel or parameter unit

Four-digit BCD or 16-bit binary (when used with option FR-A8AX)

Start signal

Forward and reverse rotation or start signal automatic self-holding input (3-wire input) can be selected.

Input signals (twelve

terminals)

Low-speed operation command, Middle-speed operation command, High-speed operation command, Second function

selection, Terminal 4 input selection, Jog operation selection, Selection of automatic restart after instantaneous power

failure, flying start, Output stop, Start self-holding selection, Forward rotation command, Reverse rotation command,

Inverter reset

The input signal can be changed using

Pr.178 to Pr.189 (input terminal function selection)

.

Pulse train input

100k pulses/s

Operational functions

Dancer feedback speed control, tension sensor feedback speed control, tension sensorless torque control, tension sensor

feedback torque control, winding diameter calculation, initial winding diameter calculation, actual line speed detection,

reduction ratio setting, maximum/minimum winding diameter setting, winding diameter / winding length storage, line speed

acceleration/deceleration function, dancer roll break detection, tension PI gain tuning, Speed control proportional gain

compensation, reel change function, taper function, inertia compensation function, mechanical loss compensation

function, maximum and minimum frequency settings, multi-speed operation, acceleration/deceleration pattern, thermal

protection, DC injection brake, starting frequency, JOG operation, output stop (MRS), stall prevention, regeneration

avoidance, frequency jump, rotation display, automatic restart after instantaneous power failure, retry function, carrier

frequency selection, fast-response current limit, forward/reverse rotation prevention, operation mode selection, slip

compensation, droop control, speed smoothing control, auto tuning, applied motor selection, gain tuning, RS-485

communication, Ethernet communication

, dancer control, cooling fan operation selection, stop selection (deceleration

stop/coasting), power-failure deceleration stop function, PLC function, life diagnosis, maintenance timer, current average

monitor, multiple rating, speed control, torque control, pre-excitation, torque limit, test run, 24 V power supply input for

control circuit, safety stop function

Output signal

Open collector output (five

terminals)

Relay output (two

terminals)

Inverter running, Up to frequency, Overload warning, Output frequency detection, Fault

The output signal can be changed using

Pr.190 to Pr.196 (output terminal function selection)

.

Fault codes of the inverter can be output (4 bits) from the open collector.

Pulse train output

50k pulses/s

Indic

at

io

n For meter

Pulse train

output (FM

type)

Max. 2.4 kHz: one terminal (output frequency)

The monitored item can be changed using

Pr.54 FM/CA terminal function selection

.

Current

output

(CA type)

Max. 20 mADC: one terminal (output current)

The monitored item can be changed using

Pr.54 FM/CA terminal function selection

.

Voltage

output

Max. 10 VDC: one terminal (output voltage)

The monitored item can be changed using

Pr.158 AM terminal function selection

.

Operation

panel

(FR-DU08)

Operating

status

Output frequency, output current, output voltage, frequency setting value

The monitored item can be changed using

Pr.52 Operation panel main monitor selection

.

Fault record

Fault record is displayed when a fault occurs. Past 8 fault records and the conditions immediately before the fault (output

voltage/current/frequency/cumulative energization time/year/month/date/time) are saved.

Summary of Contents for FR-A842-07700

Page 71: ...MEMO 70 ...

Page 91: ...MEMO 90 ...