C o o l i n g f a n s

7/5

Fitting

1. Fit the fan assembly into the interior of the server enough to connect

the ribbon cable to the small power distribution board between the

middle and bottom fans. Ensure the clips are latched onto the

connector body.

2. Slide the assembly to the left into place and fasten it to the chassis by

means of four screws at the centre spine and five screws at the side.

3.

Replace any card support struts across the motherboard.

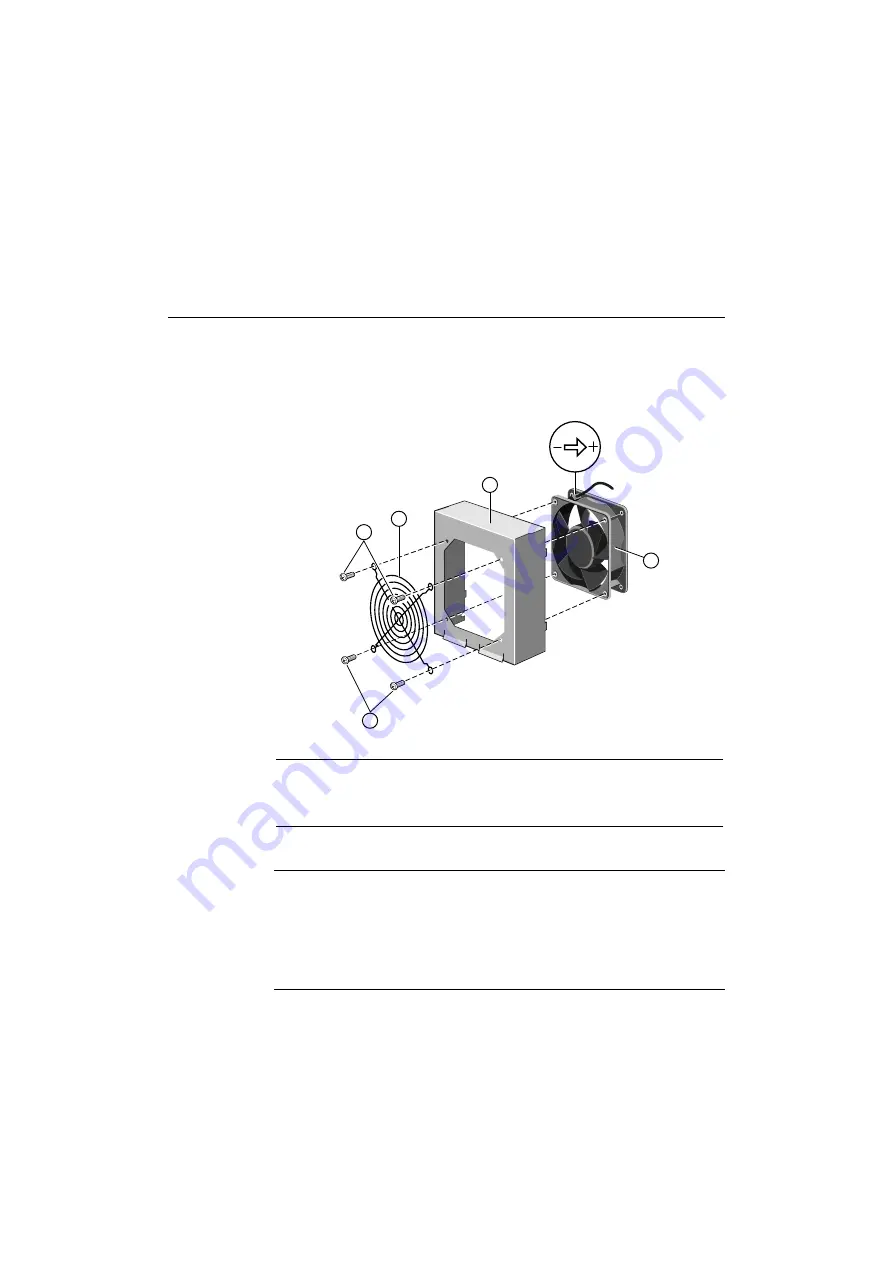

Removing fan from assembly

These following instructions apply to all the fans in the server including any

described in other chapters.

Remove the four screws which hold the handguard onto the fan assembly

housing. This not only releases the handguard, but also the fan itself.

1

2

3

1

4

Figure 7-7 Cooling Fan Assembly

1.

Securing Screws

3.

Fan Assembly Housing

2.

Handguard

4.

Fan

Fitting

Caution

Caution

Before attempting to fit the fan onto the fan assembly housing, be sure to place

the fan into the assembly so that the air flow through it is from the front of the

server to the rear (see the arrow next to the electrical polarity marking on one

corner of the fan). If any fan is turned the wrong way around, it will seriously

reduce the overall cooling effectiveness and increase the risk of overheating.

1. With the housing upright, align one corner of the handguard with a

screw hole and insert a screw just a few turns.

2. While holding the handguard and screw in place, align the fan to the

other holes and insert a second screw.

3. In a similar way, align and fit the remaining screws. Tighten when all

are in place. Do not overtighten or this may damage the fan housing.

Summary of Contents for APRICOT FT4200

Page 1: ...FT4200 Owner s Handbook NATIONAL ACCREDITATION OFCERTIFICATION BODIES ...

Page 2: ...APRICOT FT4200 OWNER S HANDBOOK ...

Page 10: ...APRICOT FT4200 Section One Startup and operating Upgrading and expansion ...

Page 36: ...APRICOT FT4200 Section Two Detailed service Information for authorised engineers ...