8

GB

D

F

I

NL

E

SW

P

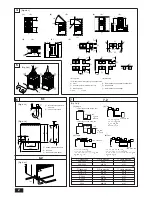

4. Space required around unit

[Fig. 4.0.1] (P.2)

<A> Top view

<B> Side view

<C> When there is little space up to an obstruction

A

Front

B

No restrictions on wall height (left and right)

C

Air outlet guide (Procured at the site)

D

Must be open

E

Wall height (H)

F

No restrictions on wall height

L

1

: 450

L

2

: 250

(1) Basic space required

A space of at least 250 mm is necessary at the back for inlet air. Taking servicing,

etc. from the rear into account, a space of about 450 mm should be provided, the

same as at the front.

(2) When there is an obstruction above the unit

(3) When inlet air enters from right and left sides of unit

•

Wall heights (H) of the front and the back sides shall be within overall height of

unit.

•

When the total height is exceeded, add the “h” dimension of the

Fig. 4.0.1

to L

1

and L

2

.

(4) When unit is surrounded by walls

Note:

•

Wall heights (H) of the front and the back sides shall be within overall

height of unit.

•

If the panel height is exceeded, add the “h” dimension of the Fig. 4.0.1 to

L

1

and L

2

.

L

1

: 450

L

2

: 250

Example:

When h is 100,

the L

1

dimension becomes 450 + 100 = 550 mm.

(5) Collective installation and continuous installation

•

Space required for collective installation and continuous installation:

When installing several units, leave the space between each block considering

passage for air and people.

•

Open in the two directions.

•

In case wall height (H) exceeds overall height of unit, add “h” dimension (h =

wall height <H> – overall height of unit) to * marked dimension.

•

If there is a wall at both the front and the rear of the unit, install up to four units

consecutively in the side direction and provide a space of 1000 mm or more as

inlet space/passage space for each four units.

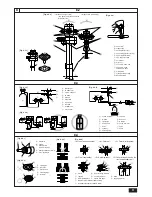

5. Lifting method and weight of product

[Fig. 5.0.1] (P.2)

Caution:

Be very careful to carry product.

- Do not have only one person to carry product if it is more than 20 kg.

- PP bands are used to pack some products. Do not use them as a mean for transportation because they are dangerous.

- Do not touch heat exchanger fins with your bare hands. Otherwise you may get a cut in your hands.

- Tear plastic packaging bag and scrap it so that children cannot play with it. Otherwise plastic packaging bag may suffocate children to death.

- When carrying in outdoor unit, be sure to support it at four points. Carrying in and lifting with 3-point support may make outdoor unit unstable, resulting in a fall of it.

6. Installation of unit

6.1. Installation

[Fig. 6.1.1] (P.2)

A

M10 anchor bolt procured at the site.

B

Corner is not seated.

•

Fix unit tightly with bolts so that unit will not fall down due to earthquake or

gust.

•

Use concrete or angle for foundation of unit.

•

Vibration may be transmitted to the installation section and noise and vibration

may be generated from the floor and walls, depending on the installation con-

ditions. Therefore, provide ample vibrationproofing (cushion pads, cushion

frame, etc.).

•

Be sure that the corners are firmly seated. If the corners are not firmly seated,

the installation feet may be bent.

Warning:

•

Be sure to install unit in a place strong enough to withstand its weight.

Any lack of strength may cause unit to fall down, resulting in a personal

injury.

•

Have installation work in order to protect against a strong wind and earth-

quake.

Any installation deficiency may cause unit to fall down, resulting in a

personal injury.

When building the foundation, give full attention to the floor strength, drain water

disposal <during operation, drain water flows out of the unit>, and piping and wir-

ing routes.

Down piping and down wiring precautions

When down piping and down wiring are performed, be sure that foundation and

base work does not block the base through holes. When down piping is performed,

make the foundation at least 100 mm high so that the piping can pass under the

bottom of the unit.

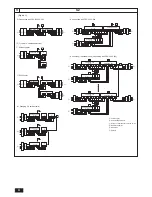

[Fig. 6.1.2]

(P.2)

A

Bottom piping through hole

B

(bolt hole)

C

(bolt hole for old models)

6.2. Connecting direction for refrigerant pip-

ing

[Fig. 6.2.1]

(P.2)

7. Refrigerant piping installation

Flare connection must be applied to the indoor unit and liquid piping of the outdoor

unit, whilst flange connection must be applied to the gas piping of the outdoor unit.

For the branching, brazing connection must be applied.

Warning:

Always use extreme care to prevent the refrigerant gas (R407C) from leaking

while using fire or flame. If the refrigerant gas comes in contact with the

flame from any source, such as a gas stove, it breaks down and generates a

poisonous gas which can cause gas poisoning. Never weld in an unventilated

room. Always conduct an inspection for gas leakage after installation of the

refrigerant piping has been completed.

7.1. Caution

1

Use the following materials for refrigeration piping.

•

Material: Use refrigerant piping made of phosphorus deoxidized copper. In

addition, be sure that the inner and outer surfaces of the pipes are clean

and free of hazardous sulphur, oxides, dust/dirt, shaving particles, oils,

moisture, or any other contaminant.

2

Commercially available piping often contains dust and other materials. Always

blow it clean with a dry inert gas.

3

Use care to prevent dust, water or other contaminants from entering the piping

during installation.

4

Reduce the number of bending portions as much as possible, and make bend-

ing radius as big as possible.

5

Always observe the restrictions on the refrigerant piping (such as rated length,

the difference between high/low pressures, and piping diameter). Failure to do

so can result in equipment failure or a decline in heating/cooling performance.