12

GB

D

F

I

NL

E

SW

P

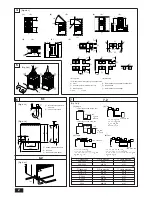

9.4. Location of wiring connections

•

Using the conduit mounting plates

Conduit mounting plates are supplied in three sizes (ø27, ø34, ø40). Choose

the size of mounting plate that matches the outer diameter of the conduit being

used.

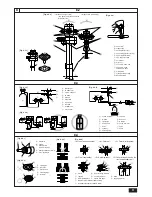

9.3. Address settings

Outdoor unit address settings

•

When controlling a group, the address must be set for each outdoor unit.

•

During address setting, set all the dip switches SW1 (3 - 6) on the board to

<when shipped from factory: all OFF>. (Address setting is not necessary for

1:1 or Free multi-component systems.)

•

Settings using SW1 are given below.

•

Please set the mutually different address, and prevent the start up simultane-

ously. (In case of connecting with PEH-P400, 500)

10. Test run

10.1. Test run

The test run can be carried out either from the outdoor unit or the indoor unit.

1. Checklist

•

After the installation, piping setup, and wiring of the indoor and outdoor units is

complete, check that refrigerant is not leaking, the power and control wires are

not loose, and the poles are not reversed. (When connecting model PEH-(R)P-

MYA in particular, check that there is current in the separate power supply

cable for the indoor unit.)

•

Use a 500 V insulation resistance tester to make sure that the resistance be-

tween the power terminal and the ground is 1.0 M

Ω

or more. If it is less than

1.0 M

Ω

, do not operate the unit. * Absolutely do not touch the tester to indoor/

outdoor connection terminals S1, S2, and S3. An accident could occur.

•

Make sure there is no malfunction in the outdoor unit. (If there is a malfunction,

you can diagnose it using LED1 on the board.)

•

Check that the ball valve is fully open on both the liquid and gas ends.

•

Check the electrical power phase. If the phase is reversed, the fan may rotate

in the wrong direction or stop, or unusual sounds may be produced.

•

Starting at least 12 hours before the test run, send current through the

crankcase heater. (If the current is running for a shorter period of time,

damage to the compressor could result.)

After the above checks are complete, carry out the test run as indicated in the

following outline.

2. Starting and finishing the test run

•

Procedure from the indoor unit: carry out the test run as in the manual provided

with the indoor unit.

•

Procedure from the outdoor unit: start and stop the test run and set test run

mode (cooling/heating) using the SW4 dip switches on the board.

1

Set test run mode (cooling/heating) using SW 4-2.

2

The test run will begin when SW 4-1 is turned ON, according to the mode

selected by SW 4-2.

3

The test run is stopped when SW 4-1 is turned OFF.

Note:

Test run mode cannot be stopped during operation by using SW 4-2. (If the

operation mode is to be changed, first stop it using SW 4-1, then after chang-

ing the operation mode, start the test run again using SW 4-1.)

•

If the 2-hour timer is set, the test run will stop automatically after 2 hours.

•

During the test run, the room temperature display on the indoor unit will indi-

cate the temperature of the indoor unit piping.

•

When you operate the test run from OC1, all trial runs are completed by OC1

→

IC1

→

MA

→

IC1

→

OC2.

cooling

run

<SW4>

heating

ON

1

2

stop

OFF

PEH-P400, 500

(IC1)

MA

OC1

OC2

SW1 function

switching

2 Error history clear

Operation by switch manipulation

Clear

Outdoor unit address

Settings 0 - 15

OFF

ON

1

2

3

4

5

6

ON

OFF

(SW1)

Ordinary

[Fig. 9.3.1] (P.5)

Model

1

–

3 Refrigerant system

address setting

4

↑

5

↑

6

↑

–

–

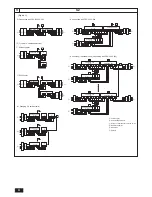

9.5. Examples of refrigerant system address

setting

Ex.

1

2

* Set the refrigerant system address of one outdoor unit to 00 for the power supply

to the remote controller.

(The refrigerant system address is set to 00 when shipped from the factory.)

Do not duplicate the refrigerant system address settings within the same system.

Indoor unit

PEH-RP200, 250MYA

PEH-P400,

500MYA

Outdoor unit

–

No.1

No.2

Outdoor unit refrigerant

system address

00

00

01~15

Remote controller

power supply unit

✕

9.6. Capacity control setting method (PEH-

P400, 500MYA only)

With the PEH-P400, 500MYA which has two outdoor units, the capacity can be

controlled to 0%, 50% or 100%.

This is set by setting the outdoor unit side dip switches as shown in the table below

before turning the power on.

DipSW5-1

No.1 side outdoor unit

OFF

No.2 side outdoor unit

ON

[Fig. 9.4.1] (P.5)

A

When installing conduct from bottom panel

B

When installing conduct from front panel

C

Mounting plate (attached)

D

Knock-out hole

Remote controller communication – reception error

Remote controller board error

Remote controller communication – transmission error

Remote controller communication – reception error

Remote controller communication – transmission error

Communication between indoor and outdoor units – reception error

Communication between indoor and outdoor units – transmission error

Communication between indoor and outdoor units – reception error

Communication between indoor and outdoor units – transmission error

Indoor/outdoor connection wiring error, indoor unit overload (5 units or more)

Indoor/outdoor connection wiring error (interference, loose)

Excessive time in use

Serial communication error

Error details

Problem location

Remote Controller

Remote Controller

Remote Controller

Indoor unit

Indoor unit

Indoor unit

Indoor unit

Outdoor unit

Outdoor unit

Outdoor unit

Outdoor unit

Outdoor unit

Outdoor unit

10.2. How to handle problems with the test run

Error code list: details

MELANS display

6831,6834

6201,6202

6832,6833

6831,6834

6832,6833

6740,6843

6841,6842

6840,6843

6841,6842

6844

6845

6846

0403

Remote controller

display

E0

E1, E2

E3

E4

E5

E6

E7

E8

E9

EA

EB

EC

ED