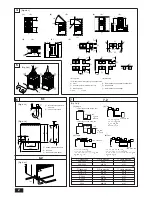

4

L1 L2 L3 N S1 S2 S3 OUT

L1 L2 L3 N S1 S2 S3

S1 S2 S3 S1 S2 S3 L1 L2 L3 N

OUT IN IN

OUT OUT IN IN

L1 L2 L3 N

L1 L2 L3 N

L1 L2 L3 N S1 S2 S3

S1 S2 S3

S1 S2 S3

L1 L2 L3 N S1 S2 S3

S1 S2 S3

S1 S2 S3

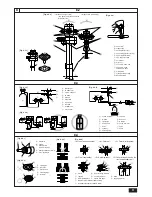

9

9.2

A

Power supply

B

Earth leakage breaker

C

Wiring circuit breaker or isolating switch

D

Remote controller

E

Indoor unit

F

Address

PEH-RP200, 250

[Fig. 9.2.1]

L1 L2 L3 N

L1 L2 L3 N

S1 S2 S3

S1 S2 S3

(1) Connecting with PEH-RP200, 250

A

B C

C

D

PUH-P200, 250

A

B

(2) Free multi - component system

1

Without heater

A

B C

D

E

E

PUH-P200, 250

(4) Connecting with PEH-P400, 500

2

With heater

B C

D

PUH-P200, 250

E

E

A

B

C

A

B

C

A

A

B C

PUH-P200, 250

F

(0)

D

A

B C

PEH-P400, 500

PUH-P200, 250

F

(1)

(3) Grouping (16 outdoor units)

A

D

E

E

E

E

PUH-P200, 250

F

(0)

PUH-P200, 250

F

(14)

PUH-P200, 250

F

(15)

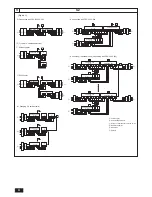

L1 L2 L3 N S1 S2 S3

S1 S2 S3

L1 L2 L3 N S1 S2 S3

S1 S2 S3

L1 L2 L3 N S1 S2 S3

S1 S2 S3

S1 S2 S3

··

·

··

B C

A

B C

B C

A

(5) Grouping (16 outdoor units) [Connecting with PEH-P400, 500]

A

B

C

L1 L2 L3 N S1 S2 S3

L1 L2 L3 N S1 S2 S3

L1 L2 L3 N S1 S2 S3

L1 L2 L3 N S1 S2 S3

S1 S2 S3 S1 S2 S3 L1 L2 L3 N

S1 S2 S3 S1 S2 S3 L1 L2 L3 N

OUT OUT IN IN

OUT OUT IN IN

OUT OUT IN IN

OUT OUT IN IN

A

B C

A

B C

PUH-P200, 250

F

(0)

PUH-P200, 250

F

(1)

PEH-P400, 500

D

A

B

C

PUH-P200, 250

F

(14)

PUH-P200, 250

F

(15)

PEH-P400, 500

A

B C

A

B C

A

B

C