Air cleaner

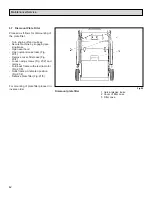

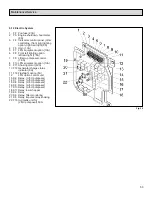

1 Air cleaner

2 Wing screw

3 Air cleaner cap with filtering insert

A soiled filtering insert may

lead to reduced performan-

ce and heavy smoking of

the engine. Never let the en-

gine run without filtering in-

sert.

Replace filtering insert as required.

Proceed as follows for dismounting

the filtering insert:

- Unscrew wing screw (Fig. 25/2) and

remove filter cap (Fig. 25/3) with

filtering insert.

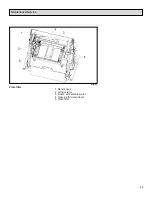

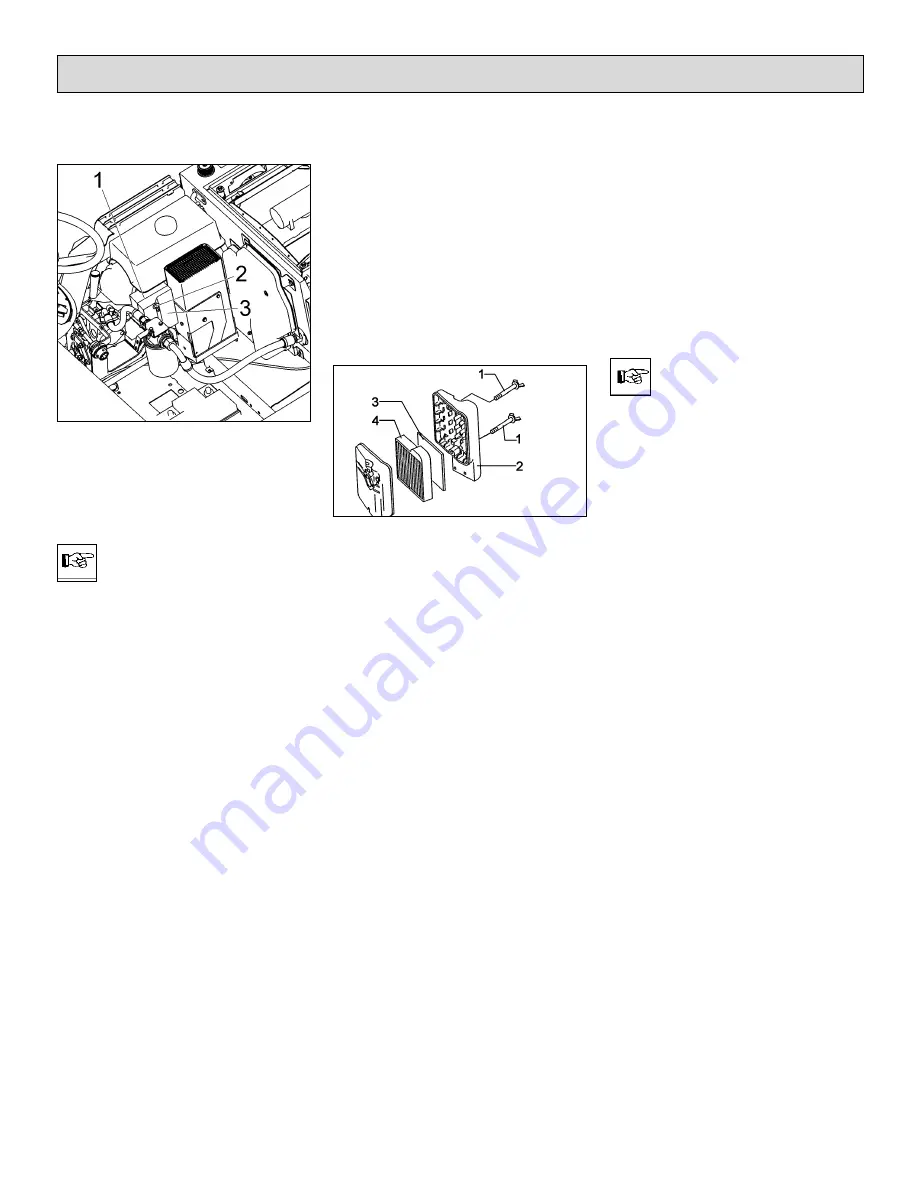

- Remove foam-type filter and paper

filter (Fig. 26/3 and 4) and proceed

to dry cleaning or replace if requi-

red.

Air cleaner components

1 Wing screw

2 Air cleaner cap

3 Foam-type filter

4 Paper filter

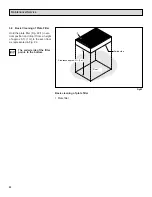

6.10 Hydraulic System

The hydraulic units are maintenance-

free. The hydraulic oil and filters are

concerned by maintenance work only.

Premature failure can be prevented

by regular inspection and periodical

maintenance (see maintenance sche-

dule).

We recommend having all

other works at the hydraulic

system done by qualified

personal.

Maintenance/Service

Fig.25

Fig. 26

47

Summary of Contents for SW5X PB40PH

Page 1: ...SW5X Model PB40PL PB40PH Instruction Manual ...

Page 62: ...62 8 Spare parts ...

Page 64: ...64 ...

Page 66: ...66 ...

Page 68: ...68 ...

Page 70: ...70 ...

Page 72: ...72 ...

Page 74: ...74 ...

Page 76: ...76 ...

Page 78: ...78 ...

Page 80: ...80 ...

Page 82: ...82 ...

Page 84: ...84 ...

Page 86: ...86 ...

Page 88: ...88 ...

Page 90: ...90 ...

Page 92: ...92 ...

Page 94: ...94 ...

Page 96: ...96 ...

Page 98: ...98 ...

Page 100: ...100 ...

Page 102: ...102 ...

Page 104: ...104 ...

Page 106: ...106 ...

Page 108: ...108 ...

Page 110: ...110 ...

Page 112: ...112 ...

Page 114: ...114 ...

Page 116: ...116 ...

Page 118: ...118 ...

Page 120: ...120 ...

Page 122: ...122 ...

Page 123: ...Set of tires Pos Part No Description 1 99652900 Set of pneumatic tyres 123 ...

Page 124: ...124 ...

Page 126: ...126 ...

Page 128: ...128 ...

Page 130: ...130 ...

Page 132: ...132 ...

Page 134: ...134 ...

Page 136: ...136 ...

Page 138: ...138 ...

Page 140: ...140 ...

Page 144: ......