3

ASSEMBL

ASSEMBL

ASSEMBL

ASSEMBL

ASSEMBLY

Y

Y

Y

Y INSTRUCTIONS

INSTRUCTIONS

INSTRUCTIONS

INSTRUCTIONS

INSTRUCTIONS

UNP

UNP

UNP

UNP

UNPACKING

ACKING

ACKING

ACKING

ACKING

1. Remove all loose items from the carton.

2. Do not discard the carton or inserts until the unit is completely assembled.

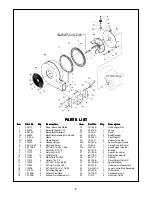

ASSEMBLING WHEELS

ASSEMBLING WHEELS

ASSEMBLING WHEELS

ASSEMBLING WHEELS

ASSEMBLING WHEELS

1. Remove the cotter pin from each end of axle. Also remove one

flatwasher from each side.

2. Lift unit and assemble wheels to axles. Replace flatwashers and

cotter pins.

NOTE: Wheels must be assembled with grease fitting in hub to

the outside. Apply a good grade of grease to wheels before

operating unit.

NOTE: See Handle Assembly on Page 7 of this owner’s guide

for reference to number used in the following instructions.

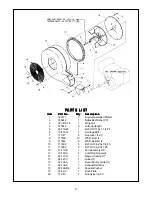

HANDLE

HANDLE

HANDLE

HANDLE

HANDLE ASSEMBL

ASSEMBL

ASSEMBL

ASSEMBL

ASSEMBLY

Y

Y

Y

Y

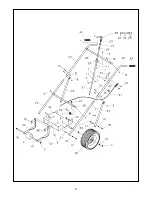

1. Remove hex head bolts (20) and hex lock nuts (29) from

the bottoms of the upper handles (1) and (2).

2. Place upper handles (1) and (2) over the ends of the

middle handles (3).

3. Align the lower holes in both upper and middle handles.

Replace hex head bolts (20), removed in Step 1, to each

of the lower holes.

4. Lift handles until the back braces (4) can be assembled

to bolts (20) assembled in Step 3. Assemble hex lock

nuts (29). DO NOT TIGHTEN.

5. Align the upper holes in both upper and middle handles.

Assemble the remaining two hex head bolts (20) and hex

lock nuts (29). DO NOT TIGHTEN.

NOTE: Check alignment of handle. The hex lock nuts have

been left loose to allow movement between the holes and

the bolts. Do not bend tubing to accomplish proper

alignment.

6. Once handles are aligned, tighten all hex lock nuts (29).

NOTE: Nuts should be tightened enough that at least two of the bolt threads extend through the nut. It

may be necessary to collapse the tubing SLIGHTLY to accomplish this.

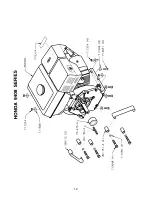

THROTTLE HOOKUP

THROTTLE HOOKUP

THROTTLE HOOKUP

THROTTLE HOOKUP

THROTTLE HOOKUP

1. Remove throttle control assembly from shipping

position.

2. Straighten the throttle cable out and run it up the left

hand handles (2) and (3).

3. Attach the throttle control (8) to the upper left hand

handle (2) with the two oval head screws (25) and

hex nuts (28) furnished.

4. Attach snap-on clamps (17) to handle to secure

throttle cable.

5. Make sure no bends are less than 8" radius.

3. Whenever the terms left or right hand, or “L” and “R”,

are used, it means from a position standing behind

the unit facing forward. All hardware is on the unit in

its proper location.