5

ASSEMBL

ASSEMBL

ASSEMBL

ASSEMBL

ASSEMBLY

Y

Y

Y

Y INSTRUCTIONS

INSTRUCTIONS

INSTRUCTIONS

INSTRUCTIONS

INSTRUCTIONS

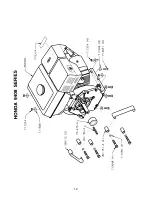

SHIFT LEVER CONNECTION

SHIFT LEVER CONNECTION

SHIFT LEVER CONNECTION

SHIFT LEVER CONNECTION

SHIFT LEVER CONNECTION

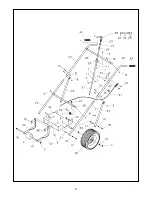

1. Remove cotter pin (18) from upper end of shifter rod (19).

2. Place end of rod thru upper hole in shift lever (13). Small pin in rod will act as a stop.

3. Replace cotter pin (18). Shifter rod (19) should pivot freely in shift lever (13).

4. Secure lower end of shifter rod (19) to shifter plate (20) as outlined above.

5. Pulling shift lever fully to the rear is reverse gear. Moving lever progressively from reverse is

neutral, 1st, 2nd, 3rd, 4th and 5th gears. Securing bracket (12) is slotted on bottom for adjustment

if necessary.

NOTE: Unit will roll freely forward and backwards with the transmission in neutral.

CLUTCH

CLUTCH

CLUTCH

CLUTCH

CLUTCH ASSEMBL

ASSEMBL

ASSEMBL

ASSEMBL

ASSEMBLY

Y

Y

Y

Y AND

AND

AND

AND

AND ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

ADJUSTMENT

1. Remove the snap clamp (26) securing the clutch cable (37) to the left middle handle (12).

2. Run the clutch cable (37) up the right hand upper handle (10) and assemble open loop of spring

(37) through hole in tab of clutch grip (35).

3. Check to make sure the lower end of clutch cable is seated in the nylon pulley (78).

NOTE: Proper assembly of the clutch cable is important as it determines the adjustment of the

clutch. Follow these instructions carefully to adjust clutch.

4. Loosen the fasteners on wire clamp (40) securing clutch cable (37) to the right middle handle

(12).

5. Slide the black outer sheath of clutch cable (37) up or down so that the metal collar on top of

sheath is 2 1/4 inches down from the center of the hex head bolt (2) securing upper cross brace

(1) to handles.

6. Measure down 6 inches from that same bolt and assemble snap clamp (26), removed in Step 1,

to upper handle and clutch cable.

7. Measure up from the bottom of the middle handle (12) to the lowest edge of the wire clamp (40).

This should be 5 1/2 inches.

NOTE: If adjustment is needed wire clamp (40) should be loosened enough to allow free movement

over cable and handle without pulling or stretching black sheath.

8. Once clamp is properly set, hold in place and tighten fasteners.

9. This should be the correct setting and no further adjustment needed. To check, depress clutch

grip (35), engaging clutch, the cable spring should be, almost or just touching nylon pulley (78).

10. If after inspection or operation the clutch would need adjustment, loosen the fasteners on the wire

clamp (40). Moving the clamp upward on handle and cable will loosen the tension of clutch.

Moving the clamp down will tighten clutch.