4

ASSEMBL

ASSEMBL

ASSEMBL

ASSEMBL

ASSEMBLY

Y

Y

Y

Y INSTRUCTIONS

INSTRUCTIONS

INSTRUCTIONS

INSTRUCTIONS

INSTRUCTIONS

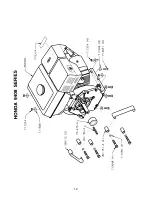

ASSEMBLING DEFLECTOR CONTROL ROD HC MODEL

ASSEMBLING DEFLECTOR CONTROL ROD HC MODEL

ASSEMBLING DEFLECTOR CONTROL ROD HC MODEL

ASSEMBLING DEFLECTOR CONTROL ROD HC MODEL

ASSEMBLING DEFLECTOR CONTROL ROD HC MODEL

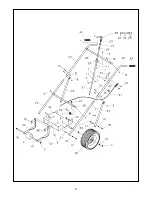

1. Remove the contour head bolt (23) lockwasher (26)

and hex nut (27) from lower end of upper control

rod (10).

2. Place lower end of upper control rod (10) down

through hole in bracket (9) on upper cross bar (5).

3. Lift free end of lower control rod (11) and place inside

lower end of upper control rod (10). Align holes and

reassemble hardware from Step 1.

OPERA

OPERA

OPERA

OPERA

OPERATION

TION

TION

TION

TION AND MAINTENANCE INSTRUCTIONS

AND MAINTENANCE INSTRUCTIONS

AND MAINTENANCE INSTRUCTIONS

AND MAINTENANCE INSTRUCTIONS

AND MAINTENANCE INSTRUCTIONS

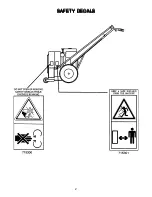

WARNING: The engine contains no oil when shipped. Read the Engine Instruction Manual and add the

proper type and amount of oil and gas before starting engine.

1. Read engine manual carefully. Be sure to know how to start

and stop engine operating unit.

2. The unit is designed to operate at full throttle, and will work

effectively by either pushing or pulling.

3. To clean an area, start at the outer perimeter and blow the

material toward the center.

4. When cleaning large areas or if debris is very dense, it may

be best to split the area into smaller plots and blow the material

into several small piles rather than one large one. As the area

being cleaned becomes smaller, reduce the engine speed to

prevent blowing the collected debris into the area already

cleaned.

HC MODELS ONL

HC MODELS ONL

HC MODELS ONL

HC MODELS ONL

HC MODELS ONLY

Y

Y

Y

Y

5. The blower housing can be adjusted to the “Hi” or “Low”

blowing position depending on the job being performed.

6. Place the blower housing in the “Low Blow” position with the

exhaust deflector straight out from side of unit for blowing dry

leaves and other light debris.

7. For blowing heavier debris such as wet leaves, twigs and

small sticks, place blower housing in “Low Blow” position with

exhaust deflector aimed downward.

8. Place the blower housing in the “Hi Blow” position for stacking

leaves in piles or windrows. The exhaust deflector should be

adjusted to achieve desired effect.

ADJUSTING BLOWER HOUSING “HI or LOW”

ADJUSTING BLOWER HOUSING “HI or LOW”

ADJUSTING BLOWER HOUSING “HI or LOW”

ADJUSTING BLOWER HOUSING “HI or LOW”

ADJUSTING BLOWER HOUSING “HI or LOW”

CAUTION: When adjusting blower housing, engine

must be shut off and spark plug wire disconnected.

1. Loosen adjusting knob, do not remove, that holds

clamp against pivot ring of blower housing.

2. Pivot blower housing to desired position and tighten

adjusting knob.

NOTE: It is not necessary to detach the deflector

control rod assembly.

3. It is possible to control the air flow from the

operating position. Turn exhaust control lever to

change deflection on angle of exhaust deflector.