8

Setting a Media

Installing the counter weight for adjusting

the take-up/ feeding tension-bar weight

Install the proper number of the counter weight depending

on the media type.

Counter weight can be installed up to three sets in each of

the right and left of the tension bar.

If you want to heavier take-up / feeding tension-bar,

please attach the weights in the following manner.

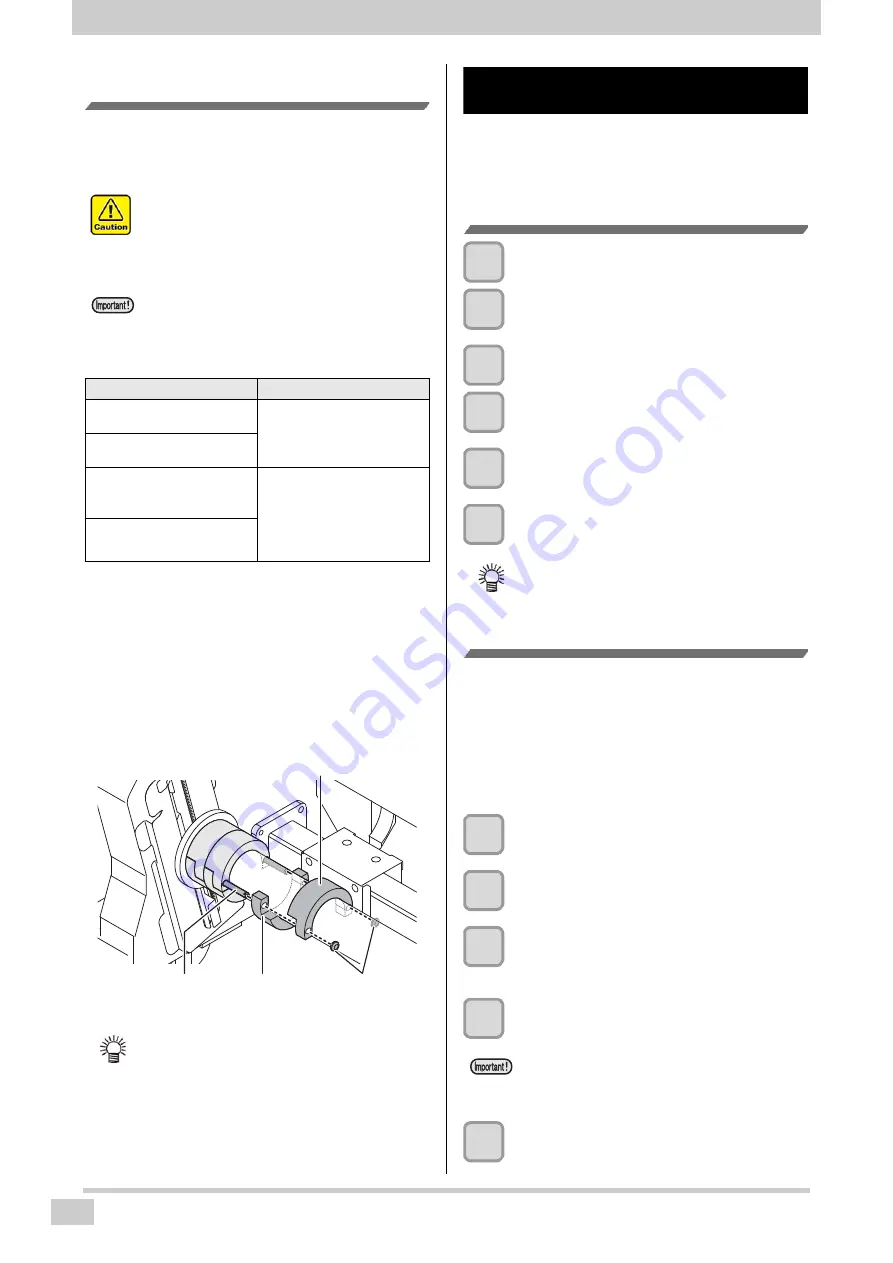

(1)

Insert a counter weight for the lower into the

mounting shaft

(2)

Insert the counter weight for the upper into the

mounting shaft, and combine with a counter weight

for the lower

(3)

Fasten the counter weight with the weight fixing

rubber

Please check the work after setting

the media

Once you have set the soft media, please execute ”Print

of the media check pattern” and ”Media confirmation feed”

in order to check if it can properly feed the media and

successfully print.

Set the tension roller to ON

1

Press the [FUNC1](MENU) in Local.

2

Press [

][

] to select “

Machine

setup

”, and press the [ENTER] key.

3

Press the [FUNC1].

4

Press [

][

] to select “

Tension

Roller

”, and press the [ENTER] key.

5

Press [

][

] to select “ON”, and press the

[ENTER] key.

6

Press the [END/POWER] key several times

to end the setting.

Perform a media check feed

In the media confirmation feed, please focus to check the

following two points.

• If the media can successfully feed

• If wrinkles do not occur in the media during the feed

If there is an abnormality in the above two points, please

adjust the weight of the tension bar by changing the

number of counterweight.

1

Press the [FUNC2](TEST PRINT/CLEANING)

in Local.

2

Press [

][

] to select “

Media Check

”,

and press the [ENTER] key.

3

Press [

][

] to select “

Feed

”, and

press the [ENTER] key.

• Execution screen will be displayed.

4

Press the[ENTER] key to start the feed

• When wrinkle occurs, please add a counterweight

to tension bar.

5

Press the [END/POWER] key several times

to end the setting.

• The weight of the counterweight will be about

500g each. (The combination of up and down, one

set is about 1kg)

• Handle the counter weight with care.

If your finger or foot is stuck in the weight, you may

be injured.

• There is no distinction between "for the upper” and

"for the lower" to the counterweight.

Counterweight can be installed either up or down.

• Not to lose the unused counter weight, put it in the

storage box.

Media condition

Solution

Ruck is generated in the media

feeding direction.

The tension applied on the

media is too strong.

According to your media,

reduce the counter weight.

The media skews at printing.

The media sags and the

machine cannot take it up

beautifully.

The tension applied on the

media is too weak.

According to your media,

increase the counter weight.

The media floats on the platen.

• If you are using the recommended media (DELUN

made 4025A), please attach12 pieces of

counterweight to the tension bar (about 6kg / top

and bottom of the combination in 6 pairs)

• When installing a counterweight to the tension bar,

please set to be on the left and right equally.

f you are using the recommended media, install

triplicate on one side.

counter weight (Up)

counter weight

(Down)

Weight

Fixing rubber

Mounting

shaft

• Setting of the tension roller can be set on the

screen after the media detection.

• If the tension bar is too heavy, the media will be

stretched. Please attach the counter weight of the

appropriate amount according to the

characteristics of the media.