Installation of Kebab MkII system

21

13

Press

to select [SET OPTION JIG].

14

Press the

key.

• The table moves downward and the Y bar moves to the rear side.

15

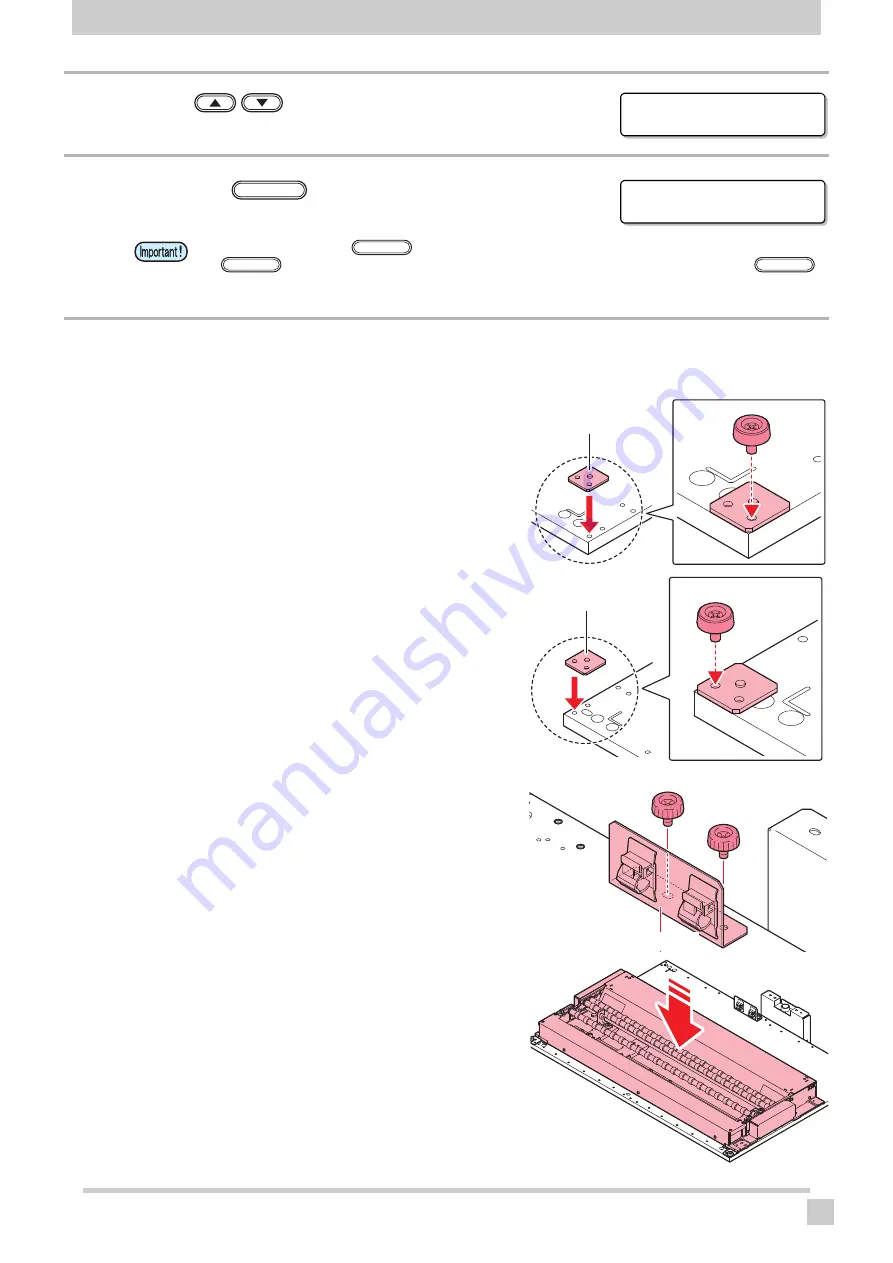

Attach the Kebab MkII L system.

• Attach the Kebab MkII L system on UJF-6042MkIIseries.

(1) Attach the K positioner BKT_R in the right front corner of

the table using a provided plastic knob screw.

(2) Attach the K positioner BKT_R in the left front corner of

the table using a provided plastic knob screw.

(3) Attach the cable BKT in the back of table.

(4) Place the Kebab MkII L system on the table.

• When you press the

key, “END [ent]” is displayed on the screen. Do not press the

key until the work up to the Step 17 has been completed. If you press the

key before the replacing work has been completed, printer starts Kebab MkII L system automatic

recognition operation.

M A C H I N E S E T U P

2 / 2

S E T O P T I O N J I G

>

S E T O P T I O N J I G

E N D

: e n t

ENTER

ENTER

ENTER

ENTER

K positioner BKT_R

K positioner BKT_R

Cable BKT