– 1.8 –

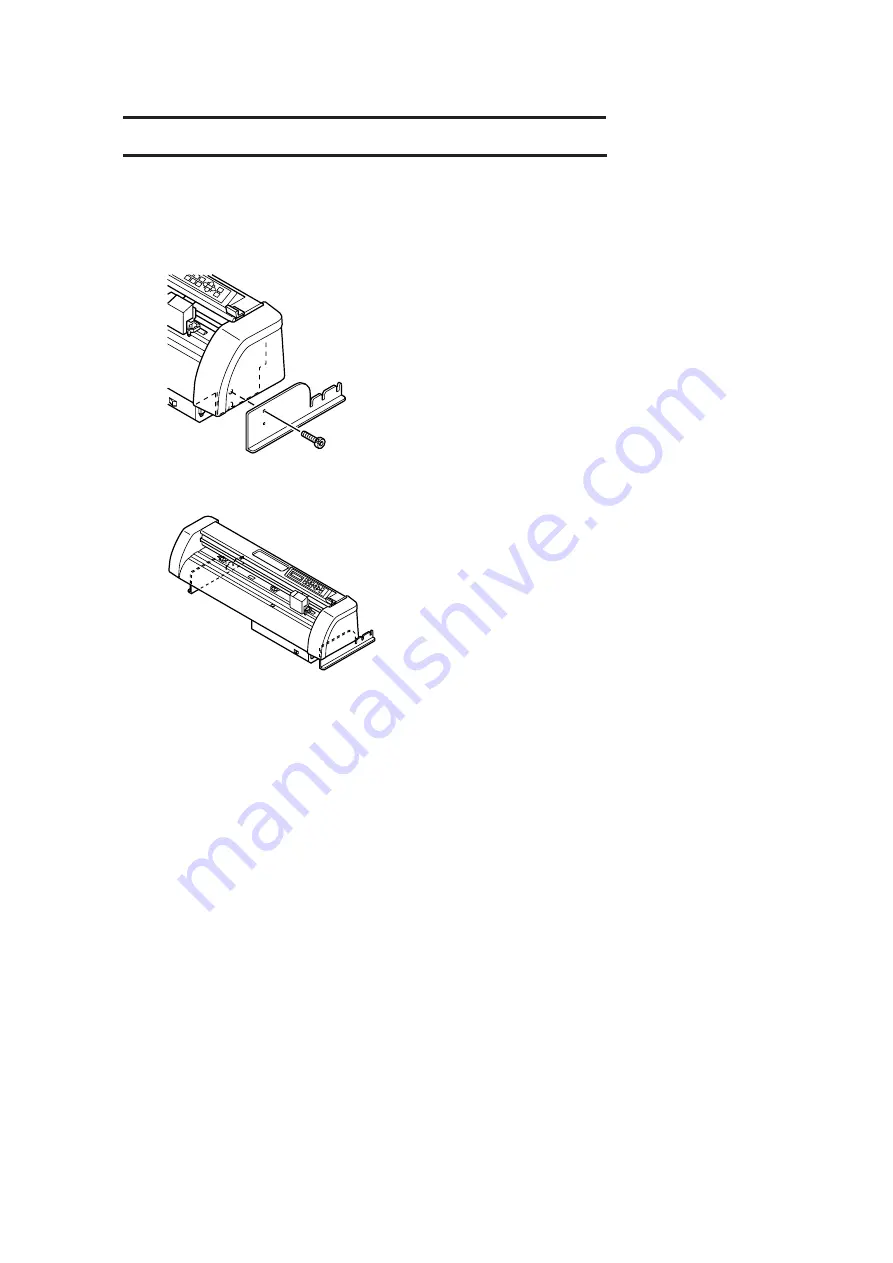

ATTACHING THE ROLL HANGERS (CG-60EX)

Mount the roll hangers following the procedures described below.

1) Fit the right-hand roll hanger to the

main unit.

Align the projection of the roll hanger with the

corresponding hole in the main unit.

Secure the roll hanger on the side plate with a

hexagon head bolt using a hexagon wrench key

supplied with the unit.

2) Mount the left-hand roll hanger follow-

ing the same procedure as described

above.

Summary of Contents for CG-100EX

Page 2: ......

Page 50: ...2 28...

Page 92: ...3 42...

Page 100: ...4 8...

Page 104: ...A 4 SAMPLE OF OUTPUT Dump list 8 bit parallel interface RS 232C interface...

Page 105: ...A 5 List...

Page 108: ...A 8 D200370 1 20 14042003...

Page 109: ......

Page 110: ...Printed in Japan D200370 MIMAKI ENGINEERING CO LTD...