Chapter 3. Routine Maintenance

PELLERIN MILNOR CORPORATION

3.1.4.2.

Procedures for Motors

—If a motor on your machine does not have grease fittings, no

grease maintenance is necessary. If a motor on your machine has grease fittings, it is necessary to

add grease. But the interval is usually longer than for other maintenance.

Table 11

gives motor

grease intervals and quantities for motors with specified frame sizes and speeds. You get this data

from the motor nameplate. Use

Table 7 in Section 3.1.2

to record the data for the motors on your

machine.

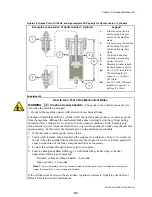

Figure 6: Motor Grease Maintenance Conditions

Grease Fitting and Grease Relief

Grease Fitting and Grease Drain

Motor Nameplate

Grease Fittings, No Reliefs or Drains

Legend

1.

Grease fitting

2.

Grease relief. Do not remove.

3.

Grease drain plug. Remove first.

4.

RPM (motor speed). This example is 1465

RPM at 50 Hz and 1765 RPM at 60 Hz.

5.

NEMA (IEC) frame size. Example: 256T

.

CAUTION 24 : Risk of damage

—You can push grease into the windings and burn out the

motor if you fail to remove the grease drain plugs.

• If the motor has grease drain plugs, remove them before you add grease. If the motor has

grease relief fittings, it is not necessary to remove them.

29

Summary of Contents for 60 Series

Page 2: ......

Page 4: ......

Page 5: ...English 1 1 ...

Page 6: ......

Page 8: ...Applicable Milnor products by model number 60044SP2 60044SP3 60044WP2 60044WP3 4 ...

Page 47: ...Deutsch 2 43 ...

Page 48: ......

Page 50: ...Anwendbare Milnor Maschinen der Modelle 60044SP2 60044SP3 60044WP2 60044WP3 46 ...