STEP 4

Now that the drive plate and wide drive rings have been removed, place a

3/16” collet into the collet holder. Insert the tip of the spindle, just above

the fork, into the collet. Once the collet is tightened, use a flat head

screwdriver to unscrew the spindle bolt. Then pull the various pieces

apart and place on your work surface.

STEP 5

You can now place the nose piece in a 13/32” collet. Unscrew the sheath

housing from it while simultaneously depressing the latch. This will

keep the flange on the nose piece from being caught up.

STEP 6

If you need to replace the latch on the sheath housing, place it over two

v-blocks. Hold a small punch or pin with a set of tweezers over one end

of the pin in the housing. Gently tap the pin out of the housing and

remove the latch and spring. The replacement latch kit is part# 40503.

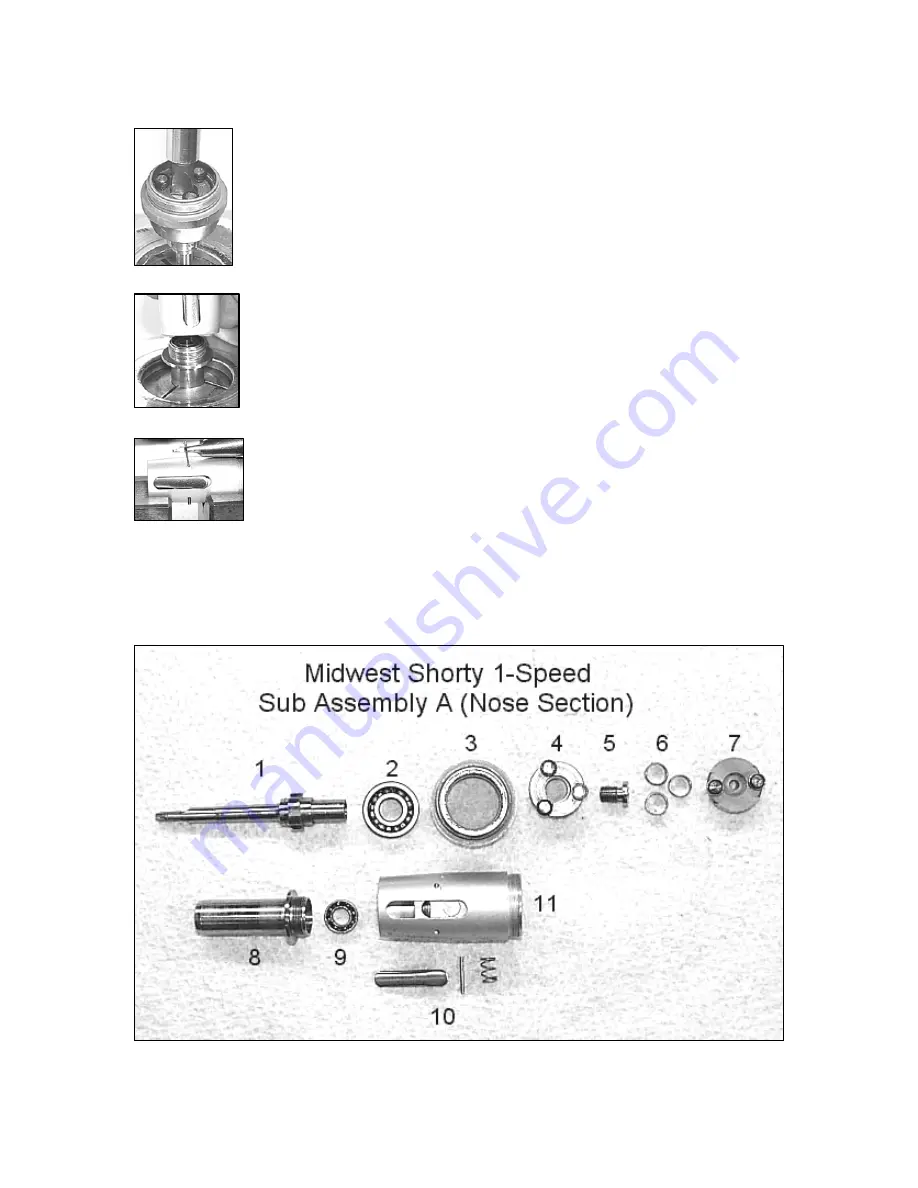

STEP 7

You can now place the component parts in your ultrasonic cleaner. After you clean the

parts, align them like the exploded view below and replace what is needed.