Flooded type water cooled screw chiller (MIC)

MCAC-CTSM-2018-1

10

The flooded evaporator makes cleaning the inside of pipes possible, and guarantees high reliability.

The discharge cut-off valve and liquid line angle valve simplify maintenance.

Simplified field wiring for easy installation.

Optimized, user-friendly operating Interface

Midea chiller adopts Midea Microprocessor which

provides advanced algorithms and reliable control.

Graphical display of the operating state, operation

scheduling, malfunction inquiry, help menu for easy

trouble shooting and other user-oriented functions.

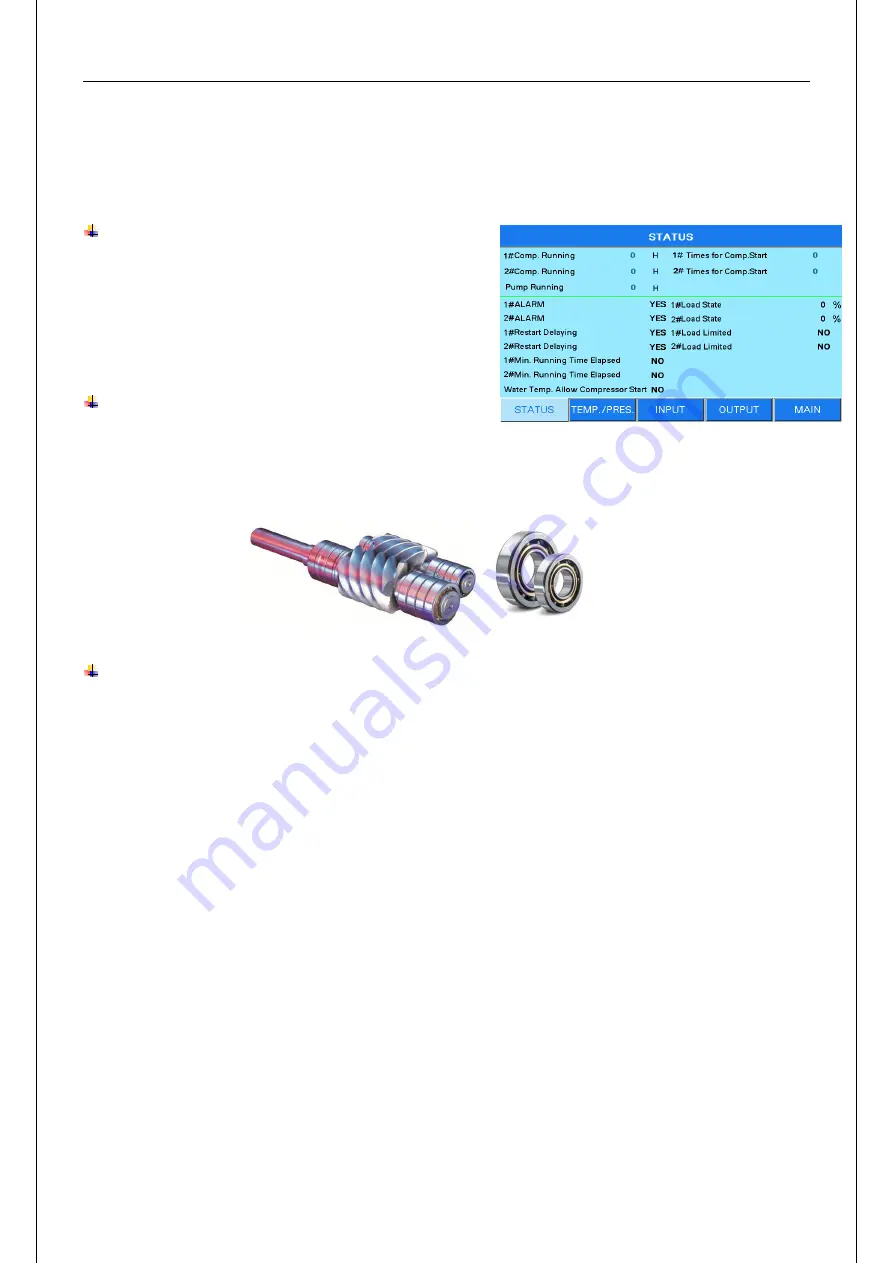

Compressor bearing

High-precision large-sized axial and radial bearings

are selected to support the male and female rotors for a long service life. With an effective

lubrication system, the bearing service life can be further extended. While the compressor is running,

lubricant is injected into all bearings due to the pressure difference.

SKF brand industry use bearing guarantees 60,000 hours of continuous working

Advanced twin-rotor screw compressor

Midea® Screw Chiller is equipped with the 3rd generation industrial Semi-hermetic Screw

compressor, which has the latest advanced 5-6 asymmetry dentiform rotors. The rotors are

processed by high-precision CNC and each part is well-proportioned and non-gap matched, which

minimizes friction and clearance loss, guaranteeing quiet running and long duration.