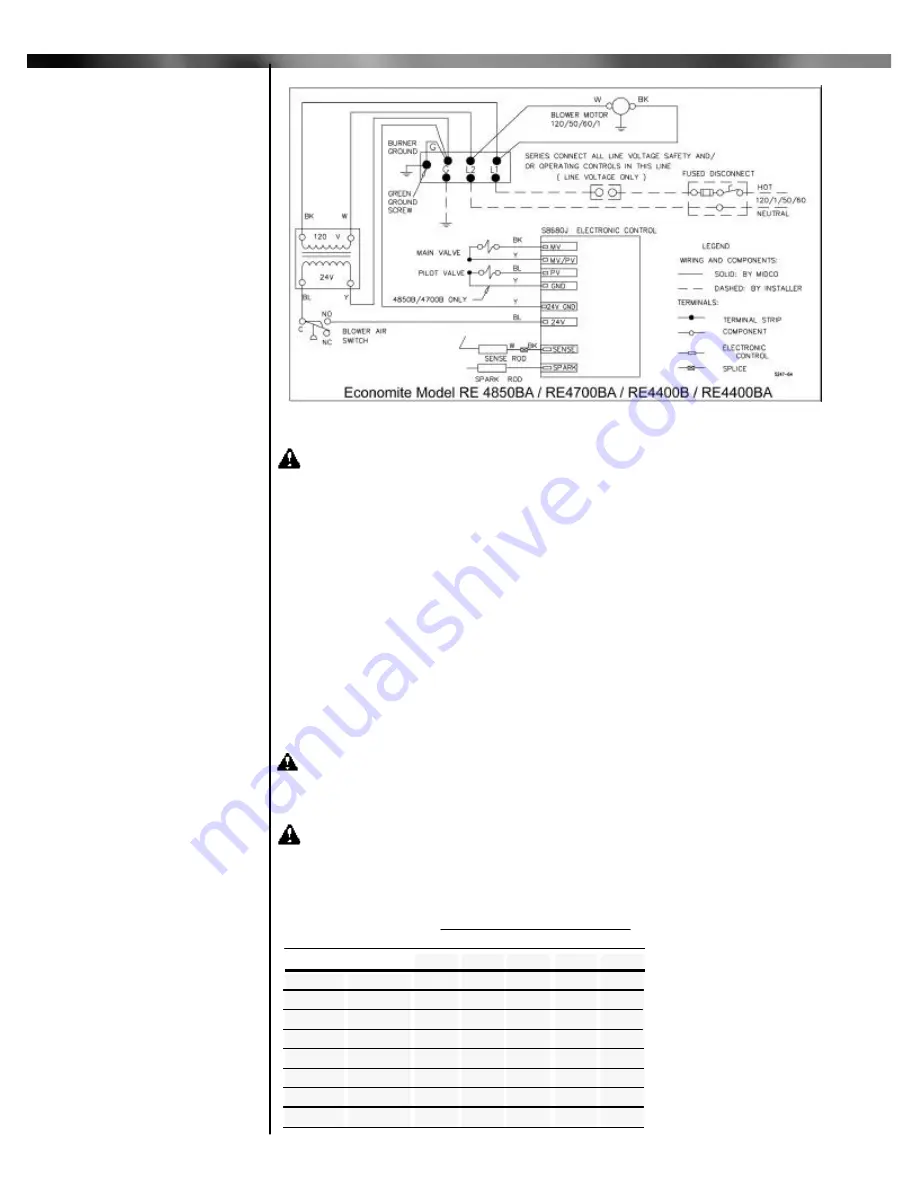

CAUTION:Refer to wiring diagram located on the inside of the burner housing

cover or above wiring diagram.

Installation wiring and grounding to the burner must conform to local codes, or, in their

absence in the

United States

to

National Electric Code, ANSI/NFPA No. 70

latest edition;

in

Canada, to Canadian Electrical Code Part 1, CSA Standard C22.1

?

Use copper wire not less than 14 gage for line voltage wiring. Hook up to a dedicated line

with an on-off disconnect switch and a minimum 10 Amp breaker.

?

The frame of the burner should be well grounded. Normally the piping and/or electric

conduit will provide sufficient grounding. However, a ground lug is located in control box for

positive grounding where insulated pipe couplings are used or where any doubt exists

regarding grounding sufficiency.

?

Confirm that the polarity is correct—hot wire to strip terminal L1, neutral L2—and that the

neutral line is not subject to induced low voltage (check L2 to earth ground) from other

equipment, as that can cause the Ignition Control Module to malfunction.

?

Each installation must include suitable limit control(s). Existing oil burner combination

operating and limit controls are normally NOT SUITABLE for gas burner use.

?

Connect motors used on forced air furnace fans or boiler pumps to a combination limit

control and switch.

?

Set the thermostat heat anticipator for the total current draw handled by the thermostat.

The current draw of the ECONOMITE 24V operating circuit is 0.9 amps.

CAUTION: Label all wires prior to disconnection when servicing controls.

Wiring errors can cause improper and dangerous operation. Verify proper operation

after servicing.

CAUTION: The available gas pressure should be within the limits shown in

SPECIFICATIONS section. Excessive pressure may damage electric valves, regulators

and manual valves. If the supply pressure exceeds the 14.0"W.C. maximum, a suitable

high pressure regulator must be installed between the Main Manual Shut-Off Valve and

burner shut-off valve as shown in Figure 5.

5

Part 1

Installation

Continued

Part 1 Installation

V

Electrical

VI

Piping

Wiring Diagram

Capacities shown are for a

total pressure drop of

0.3"W.C. For 0.5"W.C.

pressure drop, multiply

capacity shown by 1.3 .

Propane capacities shown

are for a total pressure drop

of 0.5” W.C. For higher

permissible pressure drops,

consult your gas supplier.

Table 2:

Schedule 40 NPT

Pipe-Capacity Chart

10

200

590

400

1075

900

40

275

200

500

450

1040

650

75

190

150

360

325

750

475

20

150

400

275

730

600

900

Pipe

Size

3/4

3/4

1

1

1 1/4

1 1/4

1 1/2

1 1/2

Natural

Propane

Natural

Propane

Natural

Propane

Natural

Propane

100

160

300

275

630

400

975

Approximate Capacity -MBH

Pipe Length

Type

of Gas