20 WG20 Instructions

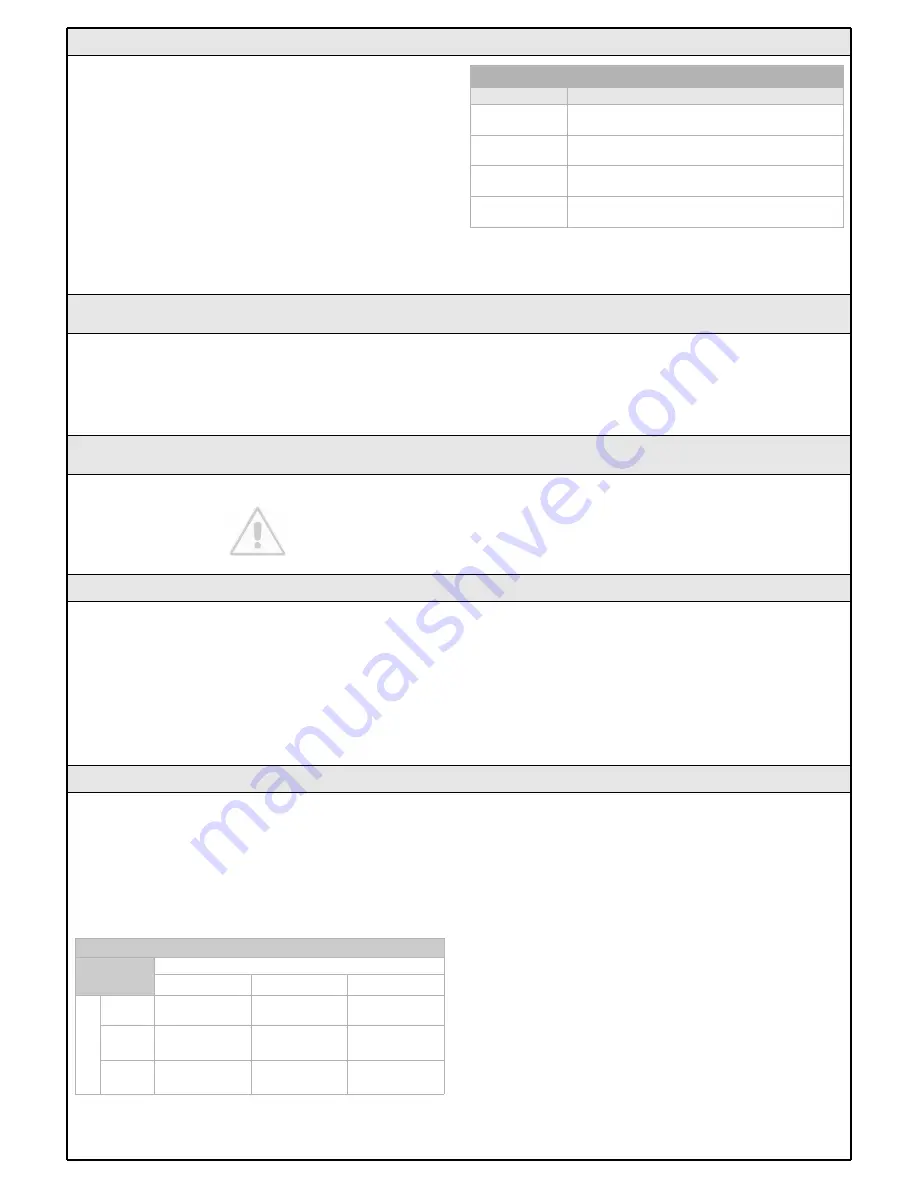

With a radio transmitter memorized in mode 1, the adjustment values for

each parameter can be checked at any time using the following

sequence:

1 Press buttons T1 and T2 on the radio transmitter simultaneously for at

least 5s.

2 Release the two buttons.

3 Within 3 seconds, perform the action described in Table 9 based on

the parameter to be checked.

4 Release the button when the flashing light starts flashing.

5 Count the flashes and, based on their number, check the

corresponding value in Table 8.

Example.

If the flashing light flashes three times after you have pressed

T1 and T2 for 5s and then button T1, the pause time is set at 40s.

5.1.2

Checking the Adjustments with the Radio Transmitter

Table 9

Parameter

Action

Pause time

Press button T1 and hold it down

Pedestrian gate

Press button T2 and hold it down

Motor force

Press button T3 and hold it down

"OPEN" function

Press button T4 and hold it down

5.2

Optional Accessories

In addition to the devices featured in WG20, other ones are available as

optional accessories designed to enhance the automation system.

PR1

: 24V buffer battery for supply in the event of power failure. It guar-

antees at last 5 complete cycles. When the system is powered by the

battery, the manoeuvre takes place only in "slow" speed mode.

PT50:

Pair of 500 mm posts with one photocell

PT100:

Pair of 1000 mm posts with two photocells

For information on the new accessories, refer to the MHOUSE catalogue

or visit the site www.mhouse.biz.

5.3

Adding or Removing Devices

Devices can be added to or removed from the WG20 automation sys-

tem at any time.

Do not add any devices until you have made sure that they are

perfectly compatible with WG20; for further information contact

MHOUSE Customer Service.

5.3.1

ECSBus

ECSBus is a system that allows you to connect the ECSBus devices

using only two wires which carry both the power supply and the com-

munication signals. All the devices are connected in parallel on the 2

wires of the ECSBus itself; each device is individually recognized

because a univocal address is assigned to it during the installation.

The photocells, as well as other devices that adopt this system, can be

connected to ECSBus, such as safety devices, control buttons, sig-

nalling lights etc. For information on the ECSBus devices, refer to the

MHOUSE catalogue or visit the site www.mhouse.biz.

The CL20 control unit recognizes to recognize all the connected devices

individually through a suitable recognition process, and can detect all the

possible abnormalities with absolute precision. For this reason, each

time a device connected to ECSBus is added or removed the control

unit must go through the recognition process; see paragraph 5.3.3

"Recognition of Other Devices".

5.3.2

STOP Input

STOP is the input that causes the immediate interruption of the

manoeuvre (with a short reverse run). Devices with output featuring

normally open "NO" contacts (like the KS1 selector switch) and devices

with normally closed "NC" contacts, as well as devices with 8.2K

Ω

constant resistance output, like sensitive edges, can be connected to

this input.

Multiple devices, even of different type, can be connected to the STOP

input if suitable arrangements are made.

To do this, proceed as described in the following table:

Note 1. The NO and NC combination can be obtained by placing the two

contacts in parallel, and placing in series to the NC contact an 8.2K

Ω

resistance (therefore, the combination of 3 devices is also possible: NO,

NC and 8.2K

Ω

).

Note 2. Any number of NO devices can be connected to each other in

parallel.

Note 3. Any number of NC devices can be connected to each other in

series.

Note 4. Only two devices with 8.2K

Ω

constant resistance output can be

connected in parallel; if needed, multiple devices must be connected "in

cascade" with a single 8.2K

Ω

termination resistance.

Warning: if the STOP input is used to connect devices with safety

functions, only the devices with 8.2K

Ω

constant resistance output

guarantee the fail-safe category 3.

During the recognition stage the control unit, like ECSBus, recognizes

the type of device connected to the STOP input; subsequently it

commands a STOP whenever a change occurs in the learned status.

Table 10

1st device type:

NO

NC

8,2k

Ω

2nd device type

NO

In parallel

(note 2)

(note 1)

In parallel

NC

(note 1)

In series

(note 3)

In series

8,2k

Ω

In parallel

In series

in parallel

(note 4)