25

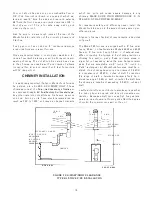

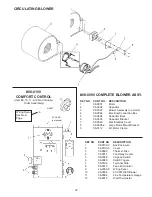

FIGURE 20 INSTALL COMFORT CONTROL CENTER AND FORCED DRAFT BLOWER

THERMOCOUPLE WIRE

INSTALL ALL CONTROL

AND HANDLE KNOBS

KNOCKOUT IN DRAFT

CHANNEL REMOVED

FORCED DRAFT

BLOWER

COMFORT CONTROL CENTER

FAN/LIMIT CONTROL

SECURE CONDUIT WITH

CONDUIT CLAMPS AND

#10 SHEET METAL SCREW

PRE-WIRED FLEXIBLE CONDUIT

TO CIRCULATING BLOWER

5. Remove the knockout section of the draft channel

on model 526 by striking sharply with a hammer. Be

careful so you do not damage the mechanism inside

the channel and directly behind the knock-out. DO

NOT allow the knock-out to fall inside the draft chan-

nel.

6. Align the forced draft blower outlet flange over the

knockout and secure with three #10 sheet metal

screws.

7. Secure conduit to furnace side using conduit clamps

and #10 sheet metal screws.

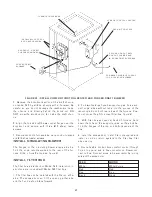

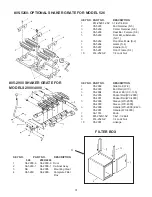

INSTALL CIRCULATING BLOWER

The flanges on the circulating blower simply slide be-

hind the angle mounts welded to the rear of the fur-

nace. Slide in from the top side, figure 21.

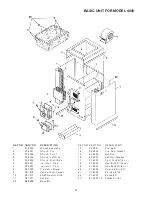

INSTALL FILTER BOX

The filter boxis standard on Model 526. Installation in-

structions are included with Model 526 filter box.

1. The filter boxcan be installed with the filter on either

side. The access door will fit the opening either side

and the handle should face forward.

2. Find two factory shipped support angles. Force sup-

port angle sides without tabs into the groove of the

mounting strip on both rear sides of the furnace. Posi-

tion at correct height to accept filter box, figure 21.

3. With filter boxset against back of furnace, bend

down the tabs on the support angles so they lock be-

hind the flanges of the top and bottom panels of the

box.

4. Install the access door. Install filter not supplied and

install a cold air return system to the filter boxfilter

side opening.

5. Route flexible conduit from comfort control through

hole in top panel and to boxconnector on blower con-

nection box. Connect wires to blower motor by joining

wires of the same color.

FEED

MOTOR

White

White/Purple

Red

Red

Blue

Blue

Black

Black