19

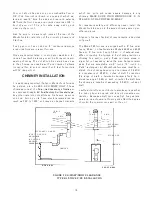

When using approved factory built metal chimneys, you

must have at least 2" of clearance when going through

a wall or next to a wall. A typical factory chimney instal-

lation is shown on figure 9.

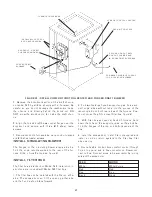

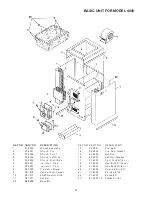

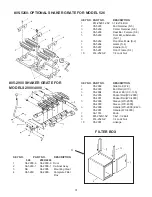

INSTALLING YOUR WOODCHUCK

Most of the Woodchuck furnace is factory assembled.

The factory assembly should be located as detailed in

the PLACEMENT AND MINIMUM CLEARANCES sec-

tion and on figure 7.

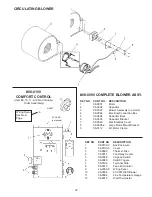

Remaining assembly will consist of mounting the con-

trols, draft and circulating blowers, filter box if used, and

electrical connection. These details will be provided af-

ter stove pipe and air duct installation.

STOVE PIPE INSTALLATION

Install your Wood/Coal unit as close to the chimney as

possible with a minimum of elbows. We recommend no

more than two elbows. The maximum horizontal run

should not exceed 6 feet with a 1/2" rise per foot. The

pipe should maintain a minimum of a 1/2" rise per foot

and NEVER be installed closer than 18" from combusti-

bles. Exceeding these recommendations normally rep-

resents creosote build-up, a smoking furnace, or one

with poor draft.

When connecting stove pipe, all joints should be se-

cured with at least three #10 sheet metal screws.

NOTE:

If it is absolutely necessary to make a run

greater than 6 feet (not recommended), use extra sup-

port brackets every 3 ft.

The connection to the wood furnace’s collar must also

be more than just a snug fit. Drill holes through the

Woodchuck’s collar and secure with sheet metal

screws. Mark each connection for cleaning. This will

prevent frustration when matching up your hole pattern

again.

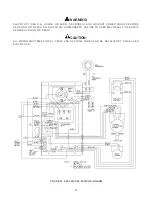

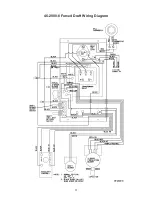

DAMPERS IN STOVE PIPES

A manual damper may be installed at a safe convenient

place between the barometric damper and the chimney.

In the event of chimney fire, it can quickly be closed

reducing draft to the chimney. See figure 10.

INSTALLATION OF A BAROMETRIC

DRAFT

Some codes and NFPA require draft regulators in the

chimney connector of wood or coal furnaces and boil-

ers, and manufacturers recommend their use with some

stoves. There is some doubt among wood heat experts

as to whether use of barometric draft regulators is wise.

Draft regulators limit the draft-the suction pulling air into

the appliance. A pivoted, counter-balanced flap is

pulled open by the draft when the draft reaches a criti-

cal amount (figure 10). This permits air to enter the

chimney, thus preventing the draft in the appliance from

rising any higher.

Use of draft regulators with oil-fired equipment is com-

mon. One objective is to keep the oil flame from being

blown out by excessive draft. This is more an annoy-

ance than a safety problem since most oil burners have

primary safety controls which stop the fuel flow into the

burner whenever the flame goes out, and modern

flame-retention burner design makes draft regulation al-

most unnecessary for this objective.

A second objective is to limit the amount of air passing

through the system in order to maintain high heat trans-

fer efficiency. Another desirable consequence is a de-

crease in peak chimney temperatures due to the added

air entering through the regulator.

High draft does not blow out the flames but fans them in

wood and coal burning equipment. An especially hot

fire can result. Control of the fire may be difficult, partic-

ularly if the wood burner is not airtight. Energy efficien-

cies may be adversely affected, and chimney fires may

be ignited. A barometric draft regulator can alleviate

these problems by limiting the flow of combustion air

into the appliance and by adding cooling air to the hot

flue gases.

However the cooling air may result in more creosote

accumulation, and if a chimney fire does start, it will be

more intense because of the draft regulator. Large

flows of air into the regulator will fan the fire in the

chimney. Thus the net effect of barometric draft

regulators is unclear-they help in some aspects, and

hurt in others. Note, though, that if a chimney is clean

so that chimney fires are impossible, a draft regulator

does no harm, and does help limit the intensity of the

fire in the appliance, and it helps prevent the flue gases

in the chimney from getting too hot. Barometric draft

regulators are recommended by JFPA for hand fired

thermostatically controlled solid fuel furnaces.

SUGGESTED TYPE

DAMPER

AIR HOLES