Page 12

Locker Controller ELS ASSIGN Touch Technical Manual

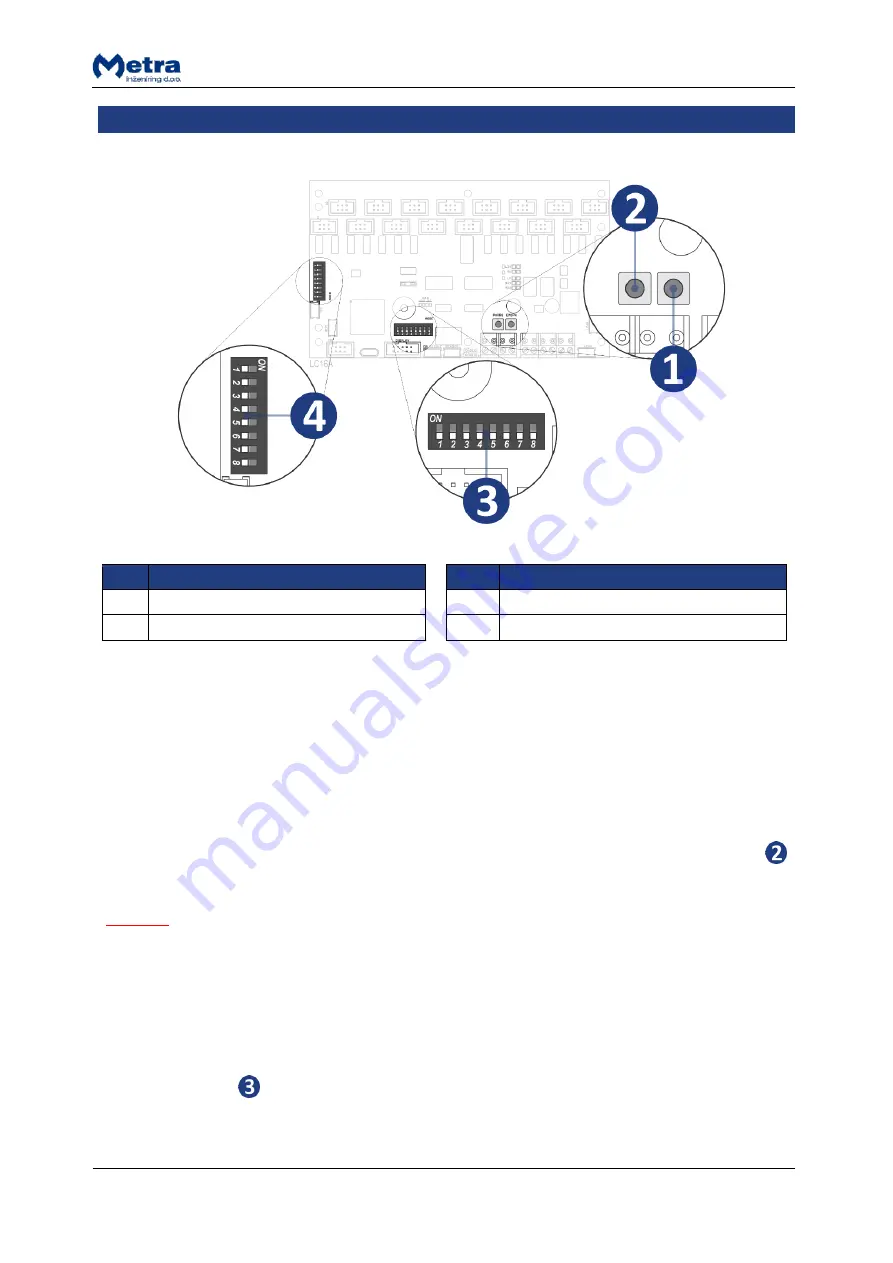

DIP switch settings

#

description

#

description

1

Emergency open pushbutton

3

Network Address DIP switch

2

Parameters request button

4

Operating Mode DIP Switch (Not used)

To change between different pins positions, use a small flat headed screwdriver or similar object to

push DIP switch pins to desired position.

STANDALONE CONFIGURATION:

After each address change power off and back on the device for the

new settings to take effect.

FULL NETWORK CONFIGURATION:

After each address change power off and back on the device for

the new settings to take effect. Operating parameters are obtained through the Metra NET Network.

The server, Display Touch and ELS Assign application on the display Touch must be set up and

running for that purpose. To obtain operating parameters, press the PARAMETERS REQUEST

button.

NOTE

Network based functionality will be present only if the server and Display Touch are running and the

Locker Controller has been properly configured.

Network address

After installation is complete, the device’s network address must be set by changing the Network

Address DIP Switch

pins positions.