16

OPERATION MANUAL

5. MAINTENANCE

• A visual inspection must be made before each use of the press, checking for leaking

hydraulic fluid and damaged, loose, or missing parts.

• Owners and/or users should be aware that repair of this equipment requires specialized

knowledge and facilities. It is recommended that a thorough annual inspection of the press

be made and that any defective parts be replaced with genuine Metalmaster parts.

• Any press which appears to be damaged in any way, is found to be badly worn, or operates

abnormally SHOULD BE REMOVED FROM SERVICE until the necessary repairs are made.

• If the press is not to be used for any length of time, store it with the ram retracted and the

operating handle in the lowered position to protect the moving parts.

5.1 INSPECTION SCHEDULE

• Check the press frame to make sure all bolts are tight and inspect for cracked welds, bent,

loose or missing parts.

• Check the hydraulic connections for leaks. Replace or properly repair any damaged or

leaking hydraulic components before using. In the event of leaking seals, oil can be topped

up via the plug on the end of the pump. Oil should be level with the bottom of the hole. If

necessary top up with hydraulic oil, This task is carried out with the ram fully retracted.

• If any rust is apparent it must be removed completely and the paint restored

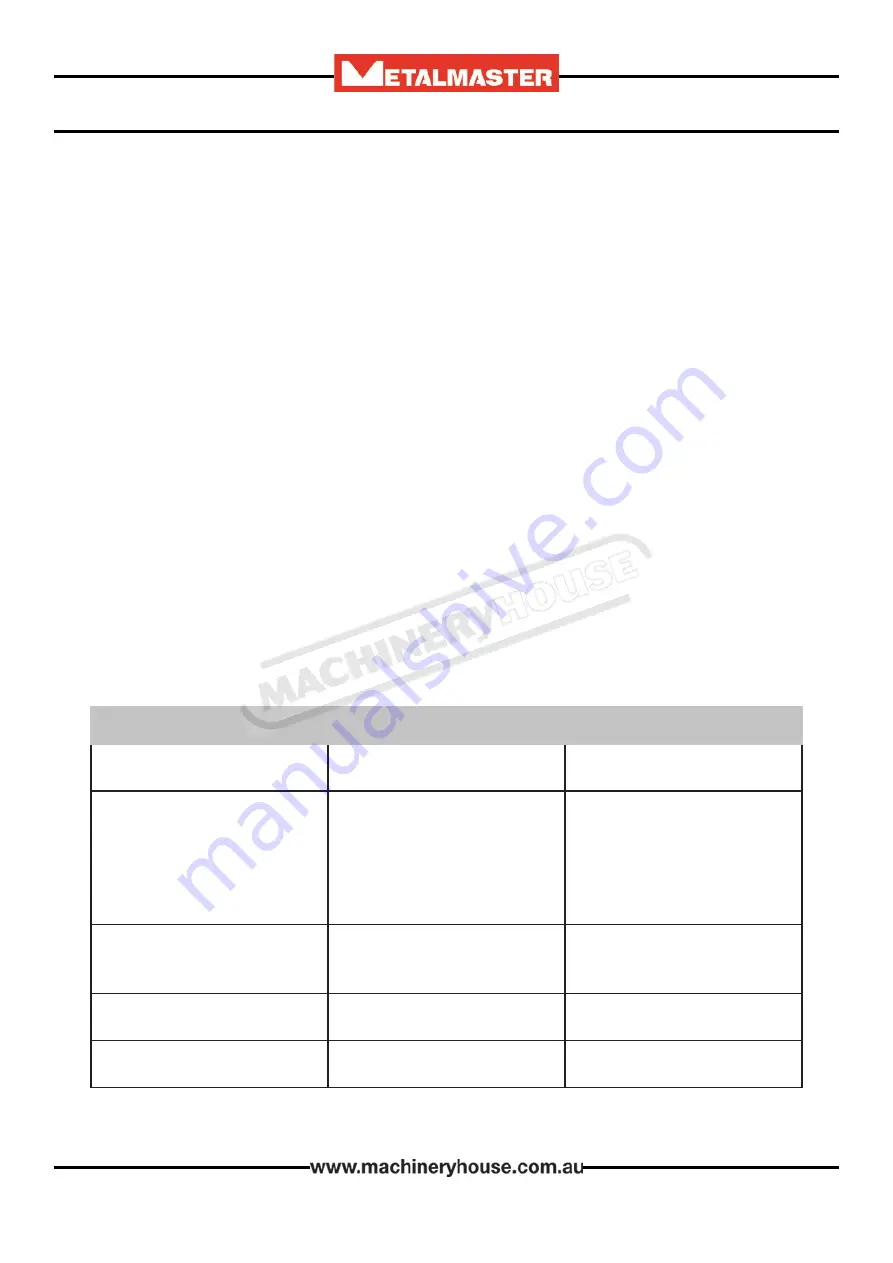

Problem

Probable Cause

Remedy

Pump unit will not work

Dirt on the valve seat/worn

seals

Bleed pump unit or have unit

overhauled with new seals

Pump will not produce

pressure. Pump feels hesitant

under load. Pump will not

lower completely

Air-lock

Open the release valve and

remove the oil filler plug.

Pump the handle a couple

of full strokes and close the

release valve.

Replace the filler plug.

Pump will not deliver

pressure

Reservoir could be overfilled

or have low oil level

Check oil level by removing

the filler plug and topping up

to the correct level.

Pump feels hesitant under

load

Pump cup seal could be worn

out

Have the cup seal replaced.

Pump will not lower

completely

Air-lock

Release air by removing the

filler plug

5.2 TROUBLESHOOTING