37

6.2.

Residual risks assessment for operation and daily servicing of the

loader

Follow these rules:

1.

Carefully read and fully understand the operating instructions.

2. Do not allow any bystanders to come near the arm at work.

3.

Do not allow children to come near the machine at work.

4.

Use the machine only as intended.

5.

Wear fitted clothes only, i.e. without any loose parts.

6.

Only the operator (after thoroughly understanding the operating instructions and the

safety regulations) is allowed to operate the loader.

7.

Inspections and repairs shall be carried out by trained personnel only.

8.

Securing the machine for the duration of repairs and daily servicing will preclude risks

to the user.

Warning! The residual risks arise if you fail to thoroughly understand

the restrictions and guidelines!

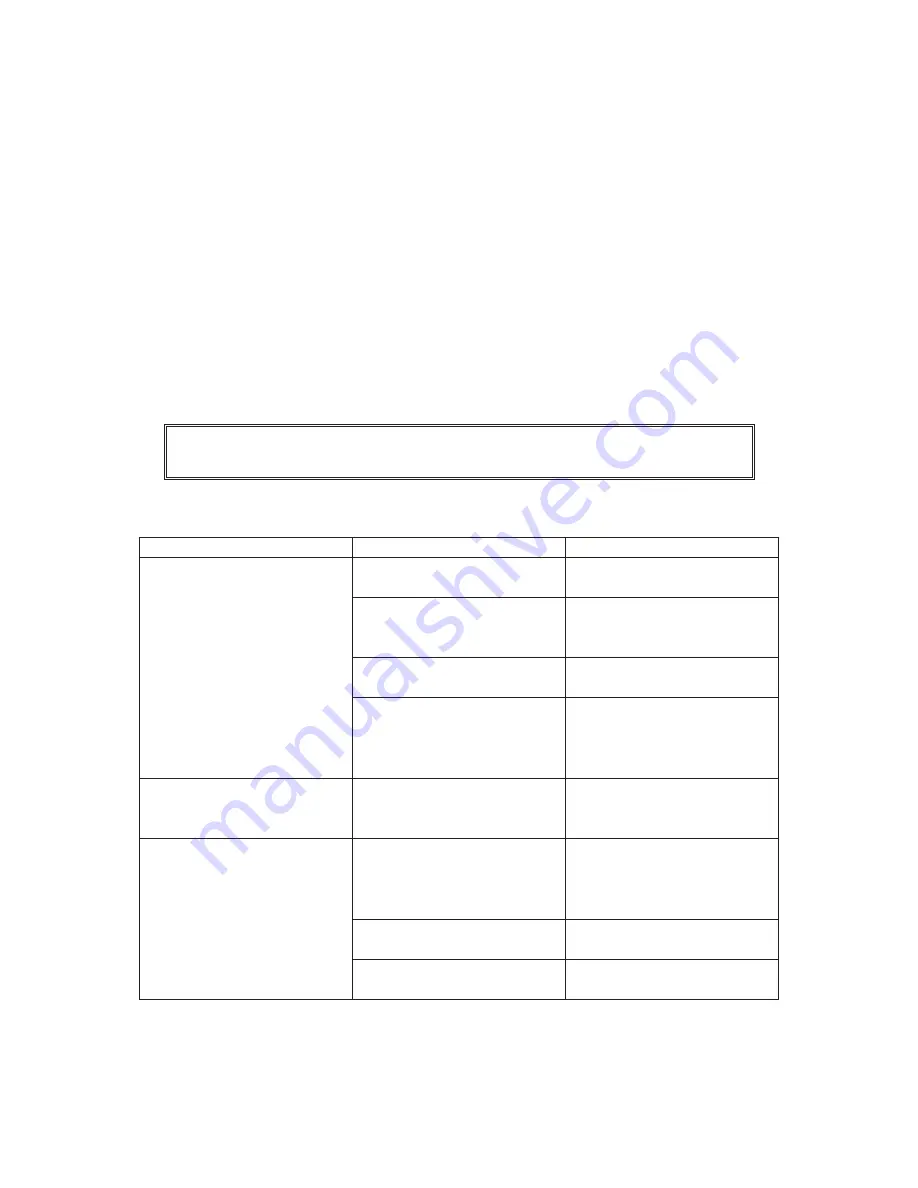

Troubleshooting

Problem

Possible cause

Remedy

Hydraulic cylinders of the

loader work incorrectly.

Not enough oil in the tractor's

hydraulic system.

Check the oil condition in the

tractor and refill if necessary.

Oil pressure in the tractor's

hydraulic system is too low.

Check pressure in the tractor's

hydraulic system with a

pressure gauge (min. 16 MPa).

Lever of the external circuit

set incorrectly.

Turn on the pump drive.

Damaged actuator.

Check the actuator's

condition, replace it with

a new one or contact the

loader's manufacturer.

The arm runs too slowly.

Not enough oil in the tractor's

hydraulic system. Low pump

capacity.

Check the oil condition and

refill if necessary.

The loader arm does not lift

loads.

Damaged actuator.

Check the actuator's

condition, replace it with

a new one or contact the

loader's manufacturer.

Not enough oil in the tractor's

hydraulic system.

Check the oil condition and

refill if necessary.

Oil pressure in the tractor's

hydraulic system is too low.

The pump is damaged or its

capacity is too low.