31

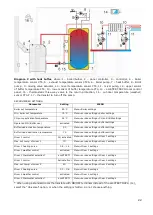

Wiring diagram of control of the switching valve in

the reserve boiler, where: 1 – ecoMAX regulator,

2 – reserve boiler, 3 – relay, 5 – switching valve

servo (with limit switches). Note: terminals

22,21,24 have to be galvanically insulated from

terminals 12,11,14.

13.14

Connection of alarm signalling

Regulator may announce alarm conditions by

activating an external device (e.g. a bell or

GSM device to send a text message).

Alarm signalling may be deactivated by

setting the H-output function to alarms.

Service Settings

→

H-output

→

H-output

function

Connection of an external alarm annunciator. 1-

regulator , 2 – external alarm annunciator, 3 –

relay

.

13.15

Connection of mixer

When connecting mixer servo,

take due care to prevent boiler

overheating, which may occur

when the flow of boiler water is

limited. You are advised to get

familiar with the position of the

valve

corresponding

to

its

maximum

opening

before

commencement of work so that

you may ensure heat collection

from the boiler at any time it is

required by opening it completely.

The regulator works only with mixing valve

servos equipped with limit switches. Use of

other servos is not allowed. The servos of full

turn time from 30 to 255 s may be used.

Description of mixer connection:

Description of mixer connection:

- connect mixer temperature sensor, -

connect mixer pump wiring,

- switch on the regulator and select proper

mixer support

in the service menu

Service settings

Mixer 1 Settings

- enter the proper

Valve Opening Time

in

Service Settings (this time should be

indicated on servo rating plate e.g. 120 s).

- connect power supply to the regulator and

switch on the regulator to start the mixer

pump,

- determine direction of servo closing/

opening. For this purpose, set the selector

Summary of Contents for ecoMAX860P2-T

Page 2: ...2...

Page 6: ......

Page 7: ...REGULATOR INSTRUCTION MANUAL ecoMAX860P2 T...

Page 19: ...19 CONTROLLER INSTALLATION AND SERVICE SETTINGS MANUAL ecoMAX860P2 T...

Page 43: ......

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......