3A-60 - 454 C.I.D. (7.4L) / 502 C.I.D. (8.2L)

90-823224--2 796

b. Index front bearing (as explained in “Impor-

tant” above), and drive it into position with

tool. Check position of oil hole(s) in bearing to

ensure bearing is positioned correctly.

c. Install rear bearing in same manner, being

sure to index bearing correctly.

3. Install a new camshaft rear plug.

IMPORTANT: Plug must be installed flush to 1/32

in. (0.8 mm) deep and must be parallel with rear

surface of cylinder block.

4. Install crankshaft and camshaft as outlined.

Cylinder Block

Cleaning and Inspection

1. Remove all engine components as previously

outlined.

2. Wash cylinder block thoroughly in cleaning sol-

vent and clean all gasket surfaces.

3. Remove oil gallery plugs and clean all oil pas-

sages.

4. Remove expansion plugs.

NOTE:These plugs may be removed with a sharp

punch, or they may be drilled and pried out.

5. Clean and inspect water passages in cylinder

block.

6. Inspect cylinder block for cracks in cylinder walls,

water jacket valve lifter bores and main bearing

webs.

7. Measure cylinder walls for taper, out-of-round or

excessive ridge at top of ring travel. This should

be done with a dial indicator or inside micrometer.

Carefully work gauge up and down cylinder to de-

termine taper and turn it to different points around

cylinder wall to determine out-of-round condition.

If cylinders exceed specifications, boring and/or

honing will be necessary.

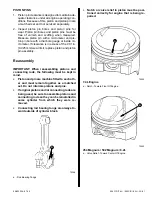

72385

b

a

b

a

Cylinder Measurement

a - Equal To Right Angle To Centerline Of Engine

b - Parallel to Centerline Of Engine ”Out Of Round” Equals

The Difference Between A and B

At Top Of Cylinder Bore and A

Measurement At Bottom Of Cylinder Bore

72570

Measuring Cylinder Bore